steel frame roll forming machine factory

The Rise of Steel Frame Roll Forming Machines in Modern Construction

In the rapidly evolving construction industry, efficiency and innovation are paramount. One technology that has significantly impacted the sector is the steel frame roll forming machine. These machines have revolutionized the way steel structures are manufactured, enabling faster production, reduced waste, and enhanced precision. As global demand for reliable and robust building materials continues to rise, the role of steel frame roll forming machines in factories has never been more crucial.

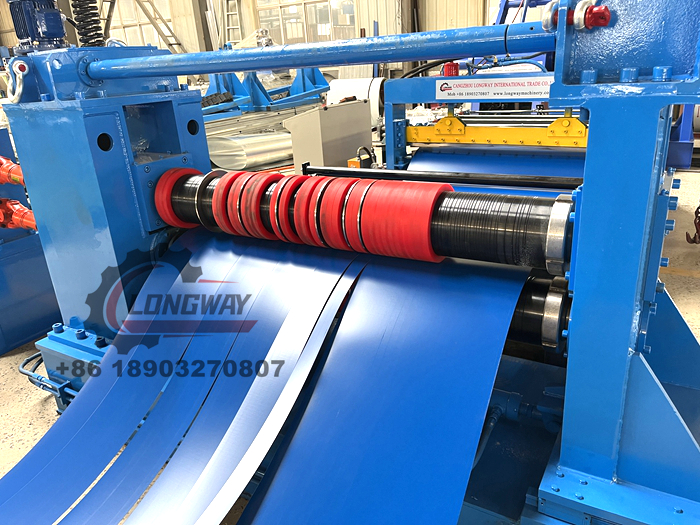

Understanding Steel Frame Roll Forming Machines

Steel frame roll forming machines are specialized equipment used to convert steel coils into various shapes and profiles. The process involves a series of rollers that gradually shape the steel into the desired configuration. This technique is particularly useful for producing steel frames, which are essential in modern architecture due to their strength, durability, and lightweight properties.

The primary advantage of using roll forming technology is its ability to create consistent profiles with high tolerances, which is critical for structural integrity. Moreover, these machines can swiftly produce long lengths of material without joints, reducing the need for additional structural support and welding.

Advantages of Steel Frame Roll Forming Machines

1. Efficiency and Speed Traditional methods of steel framing often require significant manual labor and time. In contrast, roll forming machines can operate continuously, producing large volumes of steel frames in a fraction of the time. This efficiency translates to faster construction times and enables builders to meet tight deadlines.

2. Cost-Effectiveness By minimizing manual labor and material waste, roll forming machines can significantly reduce production costs. The automated nature of these machines ensures that manufacturers can achieve economies of scale, leading to lower prices for the end products.

3. Customization Steel frame roll forming machines can be designed or adjusted to produce various profiles suited for different applications. This flexibility allows manufacturers to respond quickly to market demands and produce customized solutions for specific projects.

4. Sustainability With growing concerns about environmental impact, the construction industry is increasingly focusing on sustainable practices. Steel is 100% recyclable, and the efficient production processes employed by roll forming machines minimize waste. By optimizing the use of materials, manufacturers can significantly reduce their carbon footprint.

steel frame roll forming machine factory

Factors Driving Adoption in the Industry

Several factors contribute to the growing adoption of steel frame roll forming machines in construction factories

1. Increased Infrastructure Projects As urbanization accelerates and cities expand, there is a burgeoning demand for infrastructure development. Steel structures are favored for their strength and adaptability, creating a robust market for roll forming machines.

2. Technological Advancements Advances in technology have enhanced the capabilities of roll forming machines. Features such as computer numerical control (CNC) allow for greater precision and automation, making these machines more appealing to manufacturers.

3. Economic Factors Global economic growth has led to increased investments in construction. With a rising number of projects, the ability to produce steel frames efficiently and cost-effectively gives manufacturers a competitive edge.

4. Regulatory Compliance Building codes and regulations increasingly emphasize structural integrity and safety. Steel frames produced through roll forming meet stringent requirements, making them a preferred choice for compliance-conscious builders.

Conclusion

The steel frame roll forming machine is transforming the construction landscape by offering a faster, more efficient, and environmentally friendly alternative to traditional building methods. As technology continues to advance and market demands evolve, these machines are likely to become even more integral to construction practices worldwide. Factories equipped with steel frame roll forming technology are poised to lead the way in developing the robust infrastructure of the future while ensuring sustainability and cost-effectiveness.

In conclusion, the adoption of steel frame roll forming machines marks a significant step forward in the construction industry, combining innovation with practicality to meet the challenges of modern building projects. As we move towards a more industrialized and automated future, these machines will play a vital role in shaping our built environment.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025