Steel Frame Roll Forming Machine Manufacturer for Durable Construction Solutions

The Evolution and Significance of Steel Frame Roll Forming Machines

In the realms of modern manufacturing, steel frame roll forming machines have emerged as pivotal equipment in the construction and fabrication industries. These machines are designed to shape sheet metal into specific profiles through a continuous bending process that follows a predetermined set of rolls, making them essential for producing various structural components efficiently and accurately. As companies worldwide seek ways to enhance productivity and reduce material waste, the adoption of steel frame roll forming machines has become increasingly widespread.

Understanding the Process

The roll forming process involves feeding flat sheets of metal, typically steel, through a series of rollers that progressively shape the material into the desired profile. This method offers numerous advantages over traditional methods, including improved precision, quicker turnaround times, and broader versatility in terms of the profiles that can be produced. Steel frame roll forming machines can create complex shapes required for modern buildings, including C-channels, Z-channels, and U-shaped beams, all of which play critical roles in providing structural integrity.

Design and Technology

Modern steel frame roll forming machines incorporate advanced technology to improve performance and efficiency. Automation has become a key feature, with many machines utilizing computerized controls that allow for easy adjustments of the cutting lengths, angles, and profiles. Additionally, some machines are equipped with real-time monitoring systems that track production metrics, ensuring that even large-scale projects can maintain consistency and quality throughout the manufacturing process.

Furthermore, the materials utilized in these machines are chosen for durability and strength. High-quality steel components in the construction of the rollers and frames help withstand the intense pressure and stress encountered during operation. This not only extends the lifespan of the machines but also ensures that they maintain precision even after extensive use.

Advantages Over Traditional Manufacturing

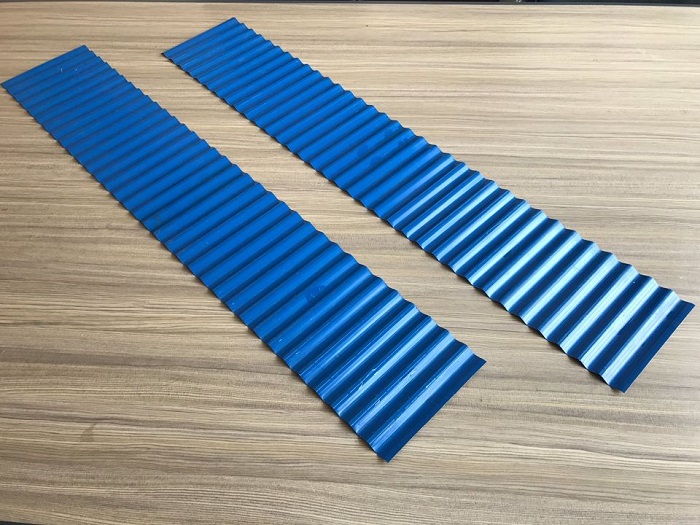

steel frame roll forming machine factory

One significant advantage of steel frame roll forming machines lies in their ability to minimize waste. Traditional cutting methods often lead to significant scrap material, whereas roll forming generates minimal waste due to its continuous operation. The efficiency gained through this process also translates to cost savings for manufacturers, allowing them to allocate resources to other critical areas of their operations.

Additionally, the ability to produce varying lengths of steel frames on demand set roll forming apart. Customization becomes more feasible, enabling producers to deliver specific designs tailored to client needs. This flexibility is invaluable in today’s fast-paced construction environment, where customer demands can change rapidly.

Applications in Construction

The construction industry has seen a substantial shift toward the use of steel frame structures, owing to their strength, durability, and rapid construction capabilities. Steel frame roll forming machines provide the necessary components for these structures, facilitating the production of roof trusses, wall panels, and even entire building frames.

Moreover, these machines are not limited to large-scale projects; they can also cater to smaller construction needs, making them ideal for various applications, from residential to commercial buildings. As sustainability continues to be a focal point of design and construction practices, steel's recyclability further elevates its status as a preferred choice for modern construction.

Conclusion

In conclusion, steel frame roll forming machines symbolize the innovation and efficiency that modern manufacturing brings to the construction industry. By streamlining the process of producing high-quality steel components, these machines not only enhance productivity but also support a shift toward more sustainable practices. As the demand for steel structures continues to grow, investment in advanced roll forming technology remains crucial for manufacturers looking to maintain competitiveness and meet evolving market needs. The future of construction is undoubtedly intertwined with the capabilities offered by steel frame roll forming machines, marking a significant evolution in how we build our environments.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025