Steel Deck Roll Forming Machine for Durable Floor Solutions and Efficient Production

The Evolution and Importance of Steel Floor Deck Roll Forming Machines

The construction industry is continuously evolving, driven by technological advancements and the need for efficient, cost-effective building solutions. One of the most significant innovations in this sector is the steel floor deck roll forming machine. This piece of equipment greatly enhances the efficiency and quality of floor systems in modern buildings, playing an essential role in the fabrication of steel floor decking.

Understanding Steel Floor Decking

Steel floor decking refers to a series of structural panels used in the construction of floors and roofs. These panels, typically made of steel, provide a sturdy framework that supports concrete slabs and other building materials. They ensure durability, safety, and longevity in a variety of applications, from residential buildings to commercial high-rises.

The integration of steel floor decking into construction projects can help reduce overall weight, allowing for more efficient structural designs and the potential to lower material costs. Precisely, the cold-formed steel floor deck panels can carry substantial loads while being lightweight, which is crucial for modern construction practices.

The Role of Roll Forming Machines

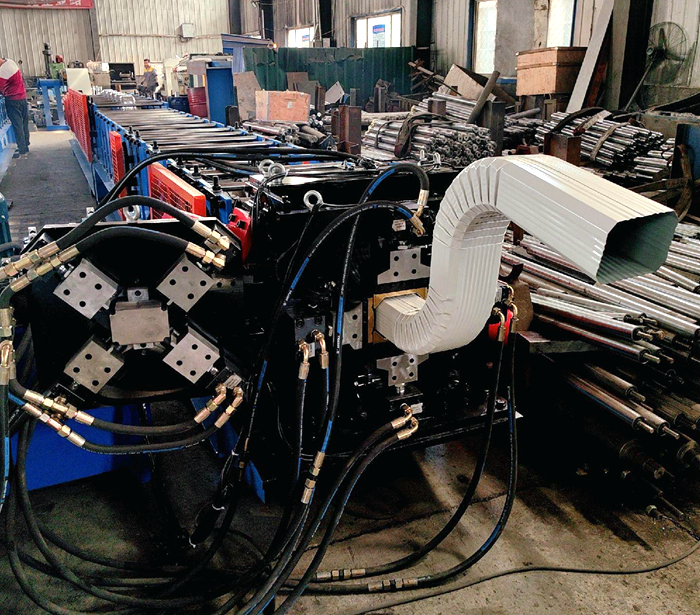

Steel floor deck roll forming machines are specialized equipment designed to produce these floor decking panels in a fast and economical manner. The roll forming process involves feeding a continuous sheet of steel through a series of rollers that gradually shape it into the desired profile. This method is highly efficient, allowing for the production of long lengths of decking with minimal waste.

One of the standout features of roll forming technology is its ability to produce custom profiles tailored to specific project needs. This flexibility enables manufacturers to cater to a diverse range of requirements, whether it’s for a commercial building with unique load requirements or residential projects needing standard specifications.

Advantages of Using Steel Floor Deck Roll Forming Machines

1. Efficiency and Speed The automated processes involved in roll forming significantly reduce production time. These machines can produce panels much faster than traditional manufacturing methods. This increase in speed translates to quicker turnaround times for construction projects, ultimately enhancing productivity.

steel floor deck roll forming machine

2. Precision and Consistency Modern roll forming machines are equipped with advanced technology that ensures high precision and uniformity in the produced panels. This consistency is vital for maintaining structural integrity and ensuring that building codes and regulations are met.

3. Cost-Effectiveness By reducing labor costs and minimizing material waste, steel floor deck roll forming machines contribute to lower production costs. Additionally, the durability and long lifespan of the steel panels can lead to cost savings over the life of a building.

4. Sustainability Steel is a sustainable material, and its recyclability makes it an eco-friendly choice for construction. Roll forming machines allow for efficient use of materials, further promoting sustainable practices within the industry.

5. Customization With the ability to create various profiles and sizes, these machines support a wide range of applications, accommodating specific architectural designs and structural requirements.

The Future of Roll Forming Technology

As the construction industry continues to embrace innovative technologies, the future of steel floor deck roll forming machines looks promising. Advances in automation, artificial intelligence, and machine learning may further enhance these machines’ capabilities, leading to even more efficient production processes.

Moreover, as sustainability becomes a focal point in construction practices worldwide, the demand for steel and eco-friendly manufacturing processes will likely see an upward trend. Roll forming machines will be central in meeting these demands, maintaining their relevance in an increasingly competitive market.

Conclusion

Steel floor deck roll forming machines represent a significant leap forward in manufacturing technology within the construction industry. Their ability to produce high-quality, consistent, and customizable steel decking efficiently makes them indispensable for modern construction practices. As technology continues to evolve, these machines' enhancements will play a critical role in shaping the future of building design and construction. With ongoing innovation, we can expect even greater advancements in efficiency and sustainability in the manufacturing processes of the materials that shape our built environment.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025