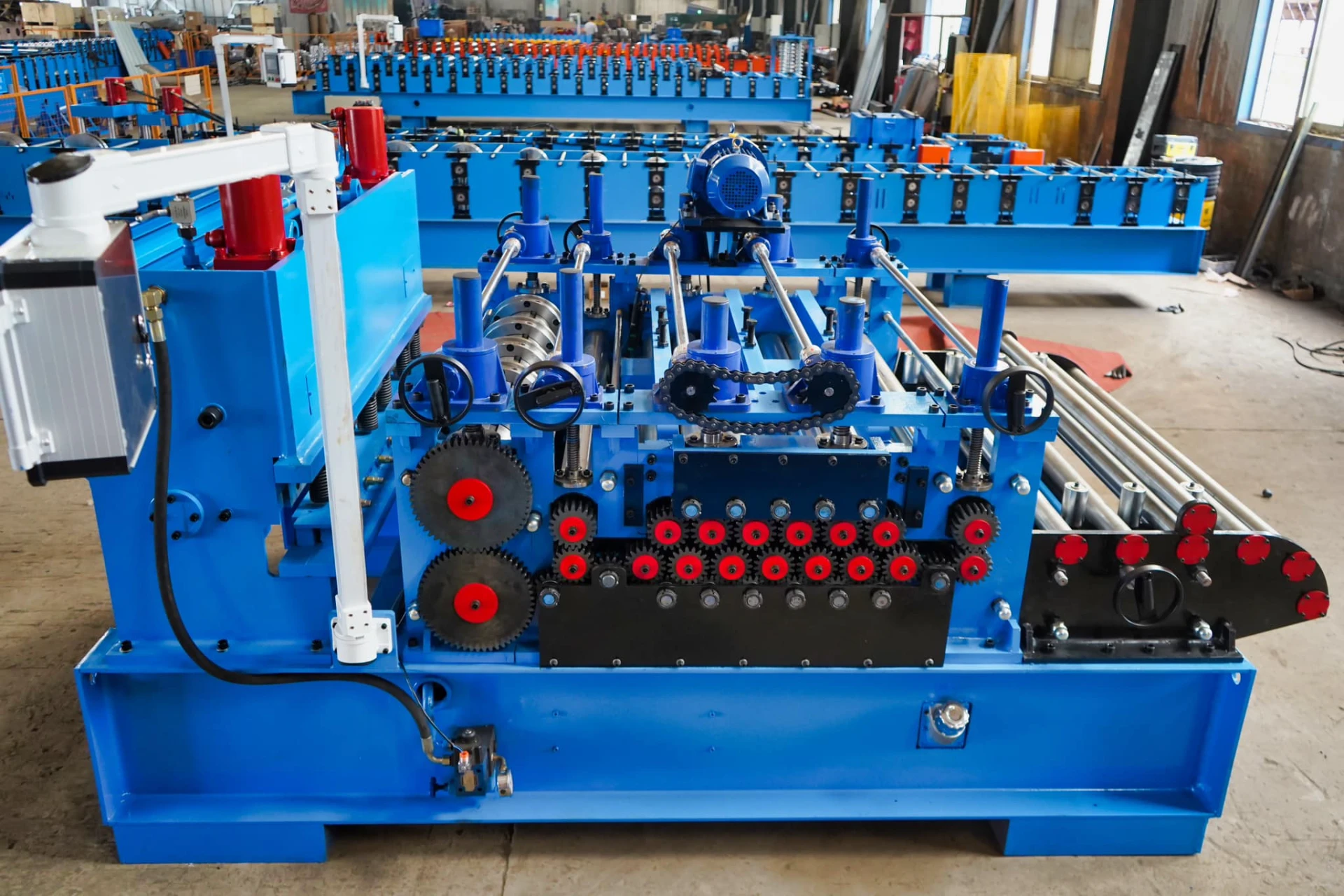

steel coil slitting machine

Understanding Steel Coil Slitting Machines An Essential Tool in Metal Processing

In the realm of metal processing, steel coil slitting machines play a pivotal role in transforming wide coils of steel into narrower strips. These machines are essential for industries where steel is a crucial component, including automotive manufacturing, construction, and appliance production. This article delves into the significance, operation, and benefits of steel coil slitting machines.

What is a Steel Coil Slitting Machine?

A steel coil slitting machine is a device designed to cut wide steel coils into narrower pieces of predetermined widths. The process involves unwinding a large coil, passing it through a series of circular blades, and then rewinding the narrower strips into new coils. These machines are automated and can handle various steel grades, thicknesses, and widths, making them versatile tools for metal fabricators.

How Does a Slitting Machine Work?

The operation of a steel coil slitting machine can be broken down into several steps

1. Uncoiling The process starts with a large coil mounted on an uncoiler, which unwinds the steel strip, ensuring a smooth and controlled flow as it enters the slitting area.

2. Slitting The unwound steel strip passes through a series of circular cutting blades mounted on a slitting head. These blades slice the steel into smaller widths according to the desired specifications. The number of blades used can vary depending on the number of strips required.

3. Rewinding After the slitting process, each narrower strip is wound onto individual reels or coils. This is typically done using a recoiler, which carefully winds the newly cut strips to prevent tangling or damage.

steel coil slitting machine

4. Quality Control Throughout the process, quality assurance measures are implemented to ensure that the dimensions and surface quality of the strips meet industry standards. Some machines are equipped with sensors and cutting-edge technology to monitor these parameters.

Benefits of Using Steel Coil Slitting Machines

1. Efficiency One of the most significant advantages of using slitting machines is their efficiency. These machines can process large coils quickly, producing numerous strips in a short amount of time. This high throughput is critical for manufacturers that need to maintain rapid production schedules.

2. Precision Modern slitting machines are designed for precision. Automated controls allow for accurate adjustments in width, ensuring that each strip meets the required specifications. This precision reduces waste and enhances the overall quality of the output.

3. Versatility Steel coil slitting machines can handle a variety of materials, including different grades of steel, stainless steel, and even non-ferrous metals. Their adaptability means that manufacturers can use a single machine to produce multiple products, saving space and investment costs.

4. Cost-Effectiveness By producing narrow strips from wide coils, slitting machines help minimize material waste. This efficient use of materials translates to significant cost savings for manufacturers, allowing them to remain competitive in the market.

5. Customization Steel coil slitting machines offer the ability to customize strip widths, allowing manufacturers to produce tailor-made products for specific applications. This flexibility is particularly advantageous in industries where custom dimensions are frequently required.

Conclusion

Steel coil slitting machines are integral to the metal processing industry, providing a streamlined solution for converting wide coils into narrower strips. Their efficiency, precision, versatility, cost-effectiveness, and customization capabilities make them indispensable for various industrial applications. As technology continues to advance, we can expect even more improvements in slitting machine performance, further enhancing their role in manufacturing processes. In a world that increasingly demands high-quality metal products, the significance of steel coil slitting machines will only continue to grow, solidifying their position as key players in the metalworking sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025