Steel Channel Framing Roll Forming Machine for Efficient Construction Solutions

The Versatility and Efficiency of Steel Channel Framing Roll Forming Machines

In today's construction and manufacturing landscape, the demand for durable and efficient materials is ever-increasing. Among the formidable options available, steel channel framing has emerged as a prime choice due to its outstanding strength-to-weight ratio, versatility, and cost-effectiveness. At the heart of this modern framing solution lies the innovative technology of steel channel framing roll forming machines.

Understanding Steel Channel Framing

Steel channel framing consists of C-shaped steel channels that provide structural support in various applications, including buildings, bridges, and industrial structures. These channels are not only robust but also lightweight, making them easier to handle and install compared to traditional framing materials. The channels exhibit excellent resistance to bending and deformation, ensuring long-lasting stability in various environmental conditions.

The Role of Roll Forming Machines

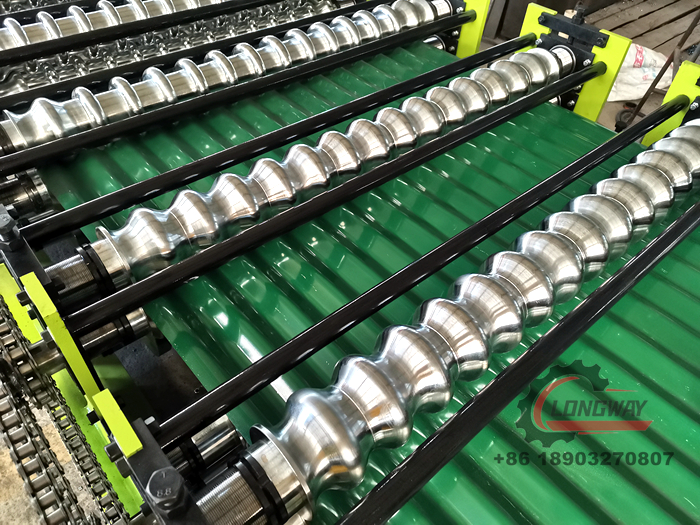

Roll forming is a continuous bending operation in which a long strip of metal is passed through consecutive pairs of rollers to create specific shapes. Steel channel framing roll forming machines are engineered to produce channels efficiently and consistently. These machines allow for intricate designs and custom lengths, catering to the diverse needs of construction projects.

The process begins with a flat steel sheet, which is fed into the machine. As the sheet moves through the rollers, it undergoes a series of bending operations to form the channel shape. The advantages of using roll forming in producing steel channels include reduced waste, high production speeds, and the ability to create complex profiles with precision.

Efficiency and Cost-Effectiveness

One of the standout features of steel channel framing roll forming machines is their ability to produce large volumes of channels in a short amount of time. This rapid production capability significantly reduces labor costs and minimizes lead times in project schedules. Moreover, the automation and precision of these machines ensure uniformity in every channel produced, leading to fewer errors and less scrap material.

steel channel framing roll forming machine

The cost-effectiveness of steel channel framing is further enhanced by its long lifespan and low maintenance requirements. Steel’s natural resistance to corrosion, especially when galvanized or treated, minimizes the need for replaceable components in the long run, making it an economically sound investment.

Applications in Construction

Steel channel framing has found a place in various sectors, including residential, commercial, and industrial construction. In residential settings, it serves as a lightweight alternative for framing walls and ceilings, thereby speeding up the building process. For commercial buildings, steel channels are essential in supporting larger structures and maintaining overall stability and safety.

Furthermore, in industrial applications, the robust nature of steel channels is ideal for creating supporting frameworks for heavy machinery and equipment. This versatility allows construction companies to utilize steel channel framing across a wide array of projects, from simple residential homes to complex industrial facilities.

Innovations in Roll Forming Technology

The evolution of roll forming technology has seen significant advancements in recent years. Modern steel channel framing roll forming machines are equipped with computer numerical control (CNC) systems for enhanced precision and customization. These innovations allow manufacturers to adjust dimensions and designs with ease, meeting specific project requirements without sacrificing quality.

Additionally, developments in material science have led to the creation of stronger and lighter steel alloys, further improving the performance of steel channel framing. The integration of smart technologies, such as IoT sensors, allows for real-time monitoring of machine performance and maintenance needs, optimizing operational efficiency.

Conclusion

Steel channel framing roll forming machines symbolize the convergence of innovation, efficiency, and versatility in construction technologies. As the industry continues to embrace advancements in manufacturing processes, the reliance on steel channel framing is likely to grow. With its robust characteristics and efficient production methods, steel channel framing is poised to be a cornerstone of modern construction, supporting projects that rise towards the future with strength and stability. The ongoing developments within this field ensure that both manufacturers and builders can meet the rising demands of a dynamic market while upholding quality and sustainability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025