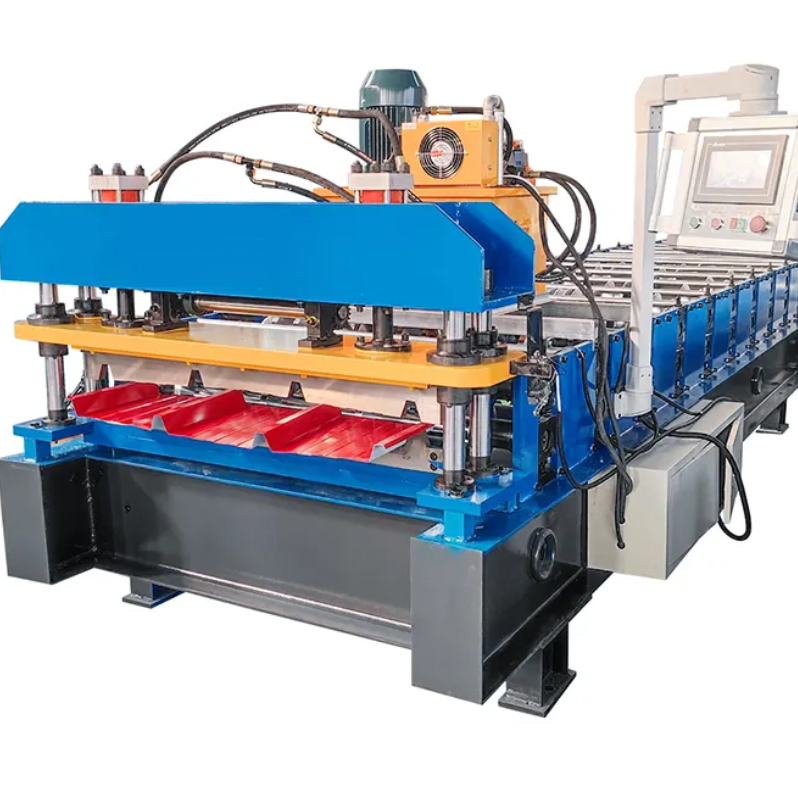

steel angle roll forming machine manufacturer

Steel Angle Roll Forming Machine Manufacturers An Overview

In the modern manufacturing landscape, the demand for high-quality steel products has significantly increased, leading to innovations in production processes. One of the essential machines that cater to these requirements is the steel angle roll forming machine. These machines are designed to produce various steel components, particularly steel angles, which are widely used in construction, automotive, and various industrial applications.

Understanding Steel Angle Roll Forming

Steel angle roll forming is a continuous process that shapes steel sheets into angular profiles. The process involves feeding flat steel sheets into a series of rollers that progressively form the steel into the desired angle. The efficiency and precision of this method make it a preferred choice for manufacturers looking to produce consistent and high-quality steel angles.

The Role of Manufacturers

Manufacturers of steel angle roll forming machines play a crucial role in ensuring that the production process is efficient and meets industry standards. These manufacturers design and engineer machines that cater to specific customer needs, offering a range of features such as adjustable speed, automatic feeding systems, and advanced control panels. This customization allows businesses to optimize their production capabilities and meet varying market demands.

steel angle roll forming machine manufacturer

Key Features of Quality Machines

When sourcing a steel angle roll forming machine, buyers should consider several key features 1. Durability Quality machines are built to withstand the rigors of continuous production. Manufacturers use high-grade materials and robust engineering practices to ensure longevity. 2. Precision The ability to produce steel angles with exact dimensions is critical. Advanced machines incorporate technologies that enhance precision in forming processes. 3. Automation Modern machines often come equipped with automated controls, reducing labor costs and increasing efficiency. Features like programmable logic controllers (PLCs) enable operators to manage the production process with greater ease. 4. Versatility The best manufacturers offer machines that can handle a variety of steel grades and thicknesses, allowing businesses to adapt to different project requirements. 5. Service and Support A reliable manufacturer provides comprehensive support, including installation, maintenance, and training services, ensuring that businesses can maximize the utility of their machines.

Choosing the Right Manufacturer

Selecting a steel angle roll forming machine manufacturer can be a daunting task, given the numerous options available on the market. It's essential to conduct thorough research, considering factors such as the manufacturer's experience, product range, customer reviews, and after-sales support. Engaging with previous customers can also provide insights into the manufacturer's reliability and the quality of their machines.

Conclusion

Steel angle roll forming machines are essential tools in the manufacturing sector, providing the efficiency and precision needed to meet the growing demands for steel products. By partnering with reputable manufacturers, businesses can enhance their production capabilities, ensuring high-quality outputs that comply with industry standards. The right machine can significantly impact a company's operational efficiency, making the selection process critical for long-term success.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025