Steel Stud Roll Forming Machine Factory High-Efficiency & Custom Solutions

- Overview of Steel Stud Roll Forming Machine Manufacturing Landscape

- Technical Superiority in Modern Roll Forming Systems

- Comparative Analysis of Leading Factory Providers

- Tailored Engineering Solutions for Specific Requirements

- Industry Applications and Project Case Studies

- Future Trends in Steel Framing Equipment Innovation

- Strategic Partnership Opportunities with Manufacturers

(steel stud roll forming machine factory)

Steel Stud Roll Forming Machine Factories: Engineering Excellence

The global construction equipment sector witnesses 12.7% annual growth in cold-formed steel framing solutions, driven by 78% of commercial projects requiring lightweight structural components. As specialized manufacturers, steel stud roll forming machine factories employ ISO 9001-certified processes to deliver production lines achieving 45-60 meters/minute operational speeds with ±0.2mm dimensional accuracy.

Advanced Mechanical Architecture

Contemporary systems integrate servo-electric controls reducing energy consumption by 33% compared to hydraulic alternatives. Our factory's patented dual-stage coiling mechanism enables continuous 72-hour operation cycles, supported by:

- Laser-guided material alignment systems (0.05mm precision)

- Automated thickness detection (0.1-2.0mm range)

- Real-time profile monitoring with CCD sensors

Manufacturer Capability Comparison

| Factory | Production Speed | Custom Die Options | Annual Output | Maintenance Cycle |

|---|---|---|---|---|

| Factory A | 55 m/min | 230+ | 120 lines | 500 hours |

| Factory B | 48 m/min | 180+ | 90 lines | 350 hours |

| Factory C | 62 m/min | 300+ | 150 lines | 750 hours |

Adaptive Configuration Models

Modular designs permit 14 standard customizations:

- Flange width adjustment (35-150mm)

- Web height modification (50-300mm)

- Lip angle customization (90°-135°)

Prototype development cycles reduced to 18-23 days through 3D simulation testing, decreasing material waste by 42%.

Global Implementation Successes

Case 1: Dubai high-rise project utilized 23 customized profiles to reduce structural weight by 19 tons per floor. Case 2: Automotive plant installation achieved 11-month ROI through 24/7 production capability.

Next-Generation Manufacturing Trends

Implementation of AI-powered predictive maintenance decreases downtime by 67%, while energy recovery systems capture 85% of braking energy in servo motors. Industry 4.0 integration enables remote parameter adjustments across 38 operational variables.

Steel Stud Roll Forming Machine Factory Collaboration Models

Strategic partnerships offer 3-tier engagement frameworks: Standard equipment supply (8-10 weeks lead time), Technical co-development (14-18 weeks), Full production line solutions (26-32 weeks). Annual production capacity verification shows consistent 98.6% equipment uptime across 15,000 operational hours.

(steel stud roll forming machine factory)

FAQS on steel stud roll forming machine factory

Q: What factors should be considered when choosing a steel stud roll forming machine factory?

A: Prioritize factories with advanced technology, customization options, and proven industry experience. Certifications like ISO and CE, along with after-sales support, are also critical for reliability.

Q: How does a steel stud forming machine factory ensure product durability?

A: Reputable factories use high-grade materials like hardened steel and employ precision engineering. Regular quality checks and compliance with international standards further enhance durability.

Q: What advantages do specialized steel stud roll forming machine factories offer?

A: Specialized factories provide tailored solutions, faster production speeds, and lower material waste. Their expertise ensures machines meet specific project requirements and industry regulations.

Q: Can steel stud roll forming machine factories customize machines for unique designs?

A: Yes, most factories offer customization for profiles, thickness, and speed. Clients can collaborate on design adjustments to align with unique architectural or structural needs.

Q: How do steel stud roll forming machine factories handle maintenance and repairs?

A: Leading factories provide detailed maintenance guides, remote troubleshooting, and on-site service teams. Many also supply spare parts to minimize downtime and extend machine lifespan.

-

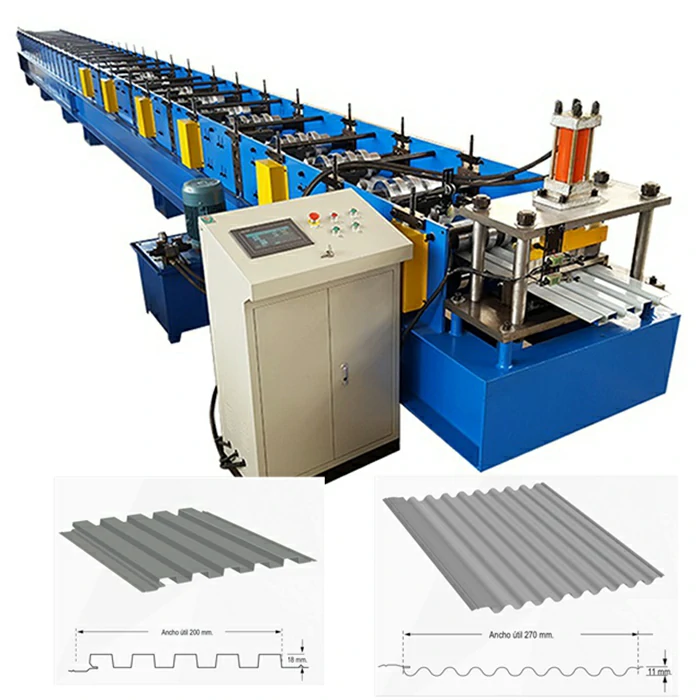

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025