Jul . 08, 2024 01:50

Back to list

Steel manufacturer specializing in roll forming for various applications in construction and manufacturing industries.

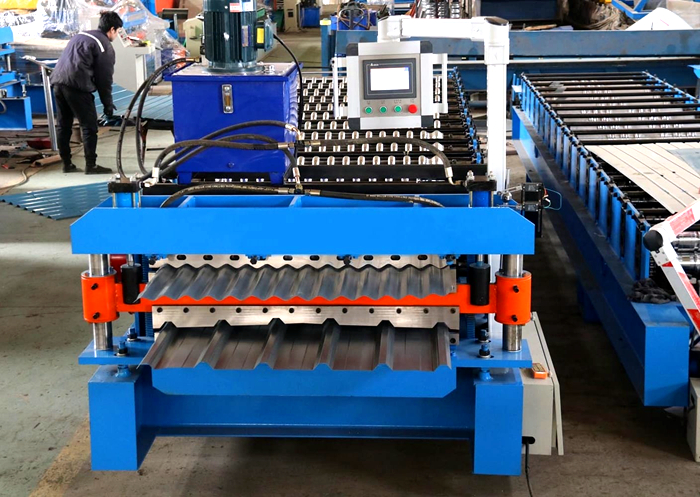

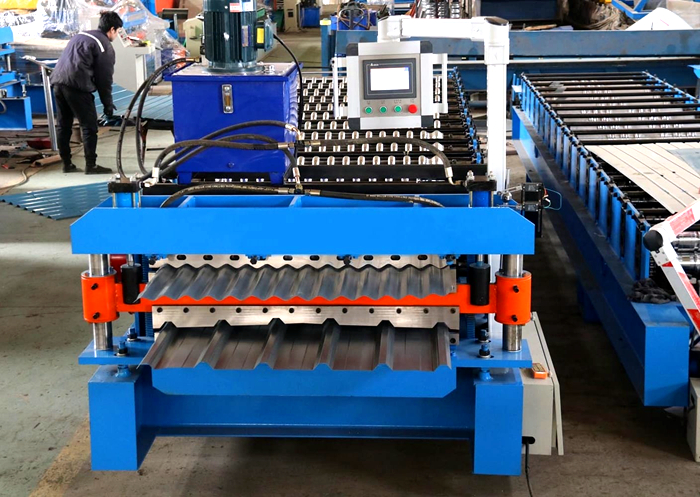

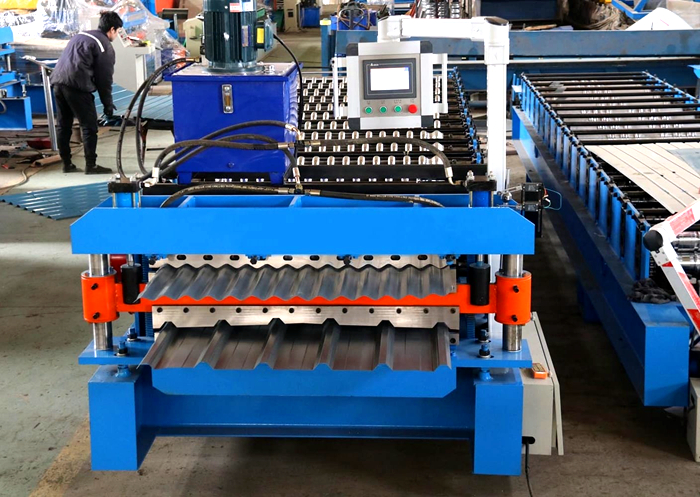

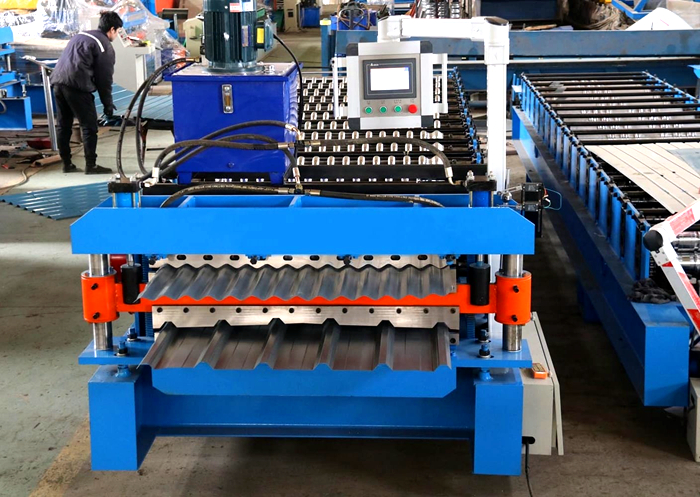

Roll forming is a cost-effective and efficient metal fabrication process that involves continuously bending a long strip of sheet metal into a desired cross-section shape. This process is often used in the manufacturing of various products, including automotive parts, building materials, and appliances. When it comes to roll forming steel, finding a reliable and experienced manufacturer is crucial for producing high-quality products.

A roll forming steel manufacturer specializes in creating custom steel profiles using the roll forming process. These manufacturers have the expertise and equipment necessary to produce precise and complex shapes from different grades of steel. With their advanced machinery and skilled technicians, they can seamlessly transform flat sheets of steel into finished products with tight tolerances and consistent quality.

One of the key advantages of working with a reputable roll forming steel manufacturer is their ability to handle large production volumes efficiently. By utilizing automated roll forming lines, they can quickly mass-produce steel components while maintaining accuracy and consistency. This makes them an ideal choice for companies looking to streamline their manufacturing processes and meet tight deadlines.

Furthermore, roll forming steel manufacturers can also offer a wide range of customization options to meet specific design requirements. They can work closely with clients to develop custom tooling and design profiles that suit their exact specifications. This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition

This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition roll forming steel manufacturer.

Quality control is another important aspect of working with a professional roll forming steel manufacturer. These companies have strict quality assurance procedures in place to ensure that every product meets industry standards and customer expectations. From raw material inspection to final product testing, manufacturers meticulously monitor every step of the production process to guarantee the highest level of quality.

In addition to producing high-quality steel products, a reliable manufacturer will also provide excellent customer service and support. They will work closely with clients to understand their needs and offer solutions that align with their budget, timeline, and quality requirements. With their technical expertise and industry experience, manufacturers can provide valuable insights and recommendations to help clients achieve their project goals.

In conclusion, choosing the right roll forming steel manufacturer is essential for companies looking to produce top-quality steel products efficiently and cost-effectively. By partnering with a reputable manufacturer, businesses can benefit from advanced technology, custom solutions, rigorous quality control, and exceptional customer service. With the help of a trusted manufacturer, companies can take their roll forming projects to the next level and stay ahead of the competition in today's competitive market.

roll forming steel manufacturer.

Quality control is another important aspect of working with a professional roll forming steel manufacturer. These companies have strict quality assurance procedures in place to ensure that every product meets industry standards and customer expectations. From raw material inspection to final product testing, manufacturers meticulously monitor every step of the production process to guarantee the highest level of quality.

In addition to producing high-quality steel products, a reliable manufacturer will also provide excellent customer service and support. They will work closely with clients to understand their needs and offer solutions that align with their budget, timeline, and quality requirements. With their technical expertise and industry experience, manufacturers can provide valuable insights and recommendations to help clients achieve their project goals.

In conclusion, choosing the right roll forming steel manufacturer is essential for companies looking to produce top-quality steel products efficiently and cost-effectively. By partnering with a reputable manufacturer, businesses can benefit from advanced technology, custom solutions, rigorous quality control, and exceptional customer service. With the help of a trusted manufacturer, companies can take their roll forming projects to the next level and stay ahead of the competition in today's competitive market.

This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition

This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition This level of flexibility allows manufacturers to produce unique and innovative steel products that set their clients apart from the competition roll forming steel manufacturer.

Quality control is another important aspect of working with a professional roll forming steel manufacturer. These companies have strict quality assurance procedures in place to ensure that every product meets industry standards and customer expectations. From raw material inspection to final product testing, manufacturers meticulously monitor every step of the production process to guarantee the highest level of quality.

In addition to producing high-quality steel products, a reliable manufacturer will also provide excellent customer service and support. They will work closely with clients to understand their needs and offer solutions that align with their budget, timeline, and quality requirements. With their technical expertise and industry experience, manufacturers can provide valuable insights and recommendations to help clients achieve their project goals.

In conclusion, choosing the right roll forming steel manufacturer is essential for companies looking to produce top-quality steel products efficiently and cost-effectively. By partnering with a reputable manufacturer, businesses can benefit from advanced technology, custom solutions, rigorous quality control, and exceptional customer service. With the help of a trusted manufacturer, companies can take their roll forming projects to the next level and stay ahead of the competition in today's competitive market.

roll forming steel manufacturer.

Quality control is another important aspect of working with a professional roll forming steel manufacturer. These companies have strict quality assurance procedures in place to ensure that every product meets industry standards and customer expectations. From raw material inspection to final product testing, manufacturers meticulously monitor every step of the production process to guarantee the highest level of quality.

In addition to producing high-quality steel products, a reliable manufacturer will also provide excellent customer service and support. They will work closely with clients to understand their needs and offer solutions that align with their budget, timeline, and quality requirements. With their technical expertise and industry experience, manufacturers can provide valuable insights and recommendations to help clients achieve their project goals.

In conclusion, choosing the right roll forming steel manufacturer is essential for companies looking to produce top-quality steel products efficiently and cost-effectively. By partnering with a reputable manufacturer, businesses can benefit from advanced technology, custom solutions, rigorous quality control, and exceptional customer service. With the help of a trusted manufacturer, companies can take their roll forming projects to the next level and stay ahead of the competition in today's competitive market. Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products