steel coil slitting machine

The Importance of Steel Coil Slitting Machines in Modern Manufacturing

In the contemporary landscape of manufacturing, efficiency and precision are paramount. One of the critical processes that contribute to achieving these goals is the slitting of steel coils. Steel coil slitting machines play a vital role in converting large rolls of steel into narrower strips, providing manufacturers with materials tailored to specific applications. This article explores the significance of steel coil slitting machines, their operational mechanisms, and their impact on various industries.

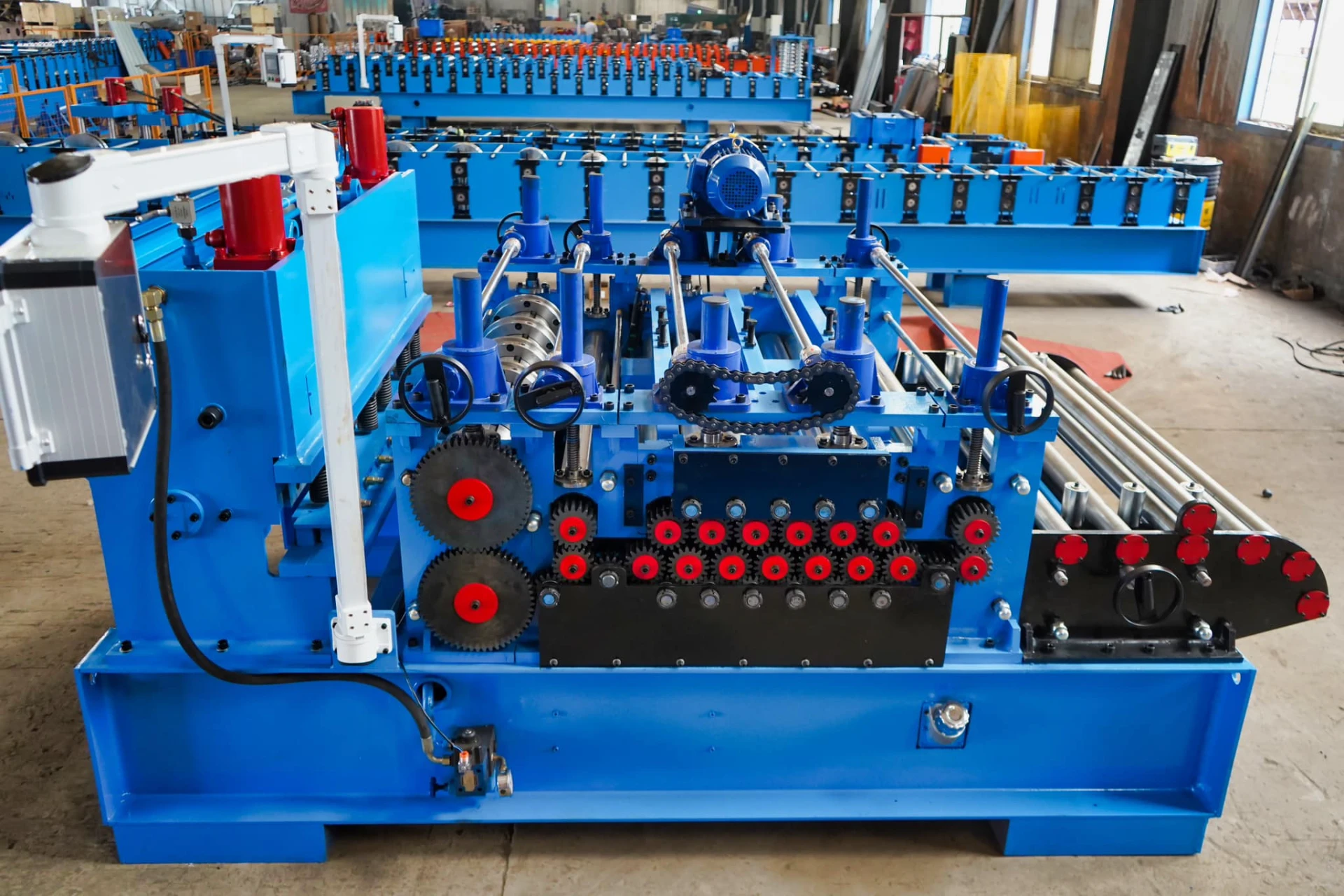

Steel coil slitting machines are specialized equipment designed to cut large coils of steel into smaller widths. These machines operate by feeding large sheets or coils into a system equipped with sharp blades that slice the material into the desired dimensions. The process involves several key components, including the entry guide, slitting heads, and rewinding system. These machines can handle various steel grades and thicknesses, making them versatile for different production requirements.

One of the primary advantages of utilizing slitting machines is the increase in operational efficiency. Traditionally, the manual process of cutting steel was labor-intensive and often led to inconsistencies in product quality. With the introduction of automated slitting machines, manufacturers can enhance their production lines by reducing manual intervention, minimizing waste, and improving overall productivity. High-speed slitting machines can process coils at remarkable rates, enabling manufacturers to meet the rising demand for steel products in a timely manner.

steel coil slitting machine

Moreover, the precision offered by steel coil slitting machines cannot be overlooked. Modern machines are equipped with advanced technologies such as computer numerical control (CNC), which ensures accurate cutting tolerances and uniform strip widths. This level of precision is critical for industries that require specific material specifications, such as automotive, construction, and appliance manufacturing. Consistency in the quality of steel strips helps manufacturers maintain compliance with industry standards and enhance the performance of their end products.

In addition to efficiency and precision, steel coil slitting machines contribute to the overall cost-effectiveness of production. By enabling manufacturers to create customized widths and lengths, these machines allow for better inventory management and reduced scrap material. Businesses can optimize their steel usage and reduce the costs associated with excess material, leading to enhanced profitability. Furthermore, the availability of specialized strips opens up opportunities for manufacturers to explore new market segments and applications.

As industries continue to evolve, the demand for high-quality steel products remains robust. Steel coil slitting machines are essential tools that empower manufacturers to adapt to this dynamic landscape. Their ability to provide tailored solutions, coupled with advanced technologies, positions them as a cornerstone of modern manufacturing. As manufacturers strive for excellence in production, the role of steel coil slitting machines will only become more significant.

In conclusion, steel coil slitting machines are indispensable assets in the manufacturing sector. They enhance efficiency, precision, and cost-effectiveness, making them vital for industries reliant on steel products. As technology advances, these machines will continue to evolve, ensuring that manufacturers can meet future challenges and demands head-on. Investing in high-quality slitting machines will undoubtedly pay dividends in productivity and competitiveness for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025