standing seam roofing machine factory

The Evolution and Importance of Standing Seam Roofing Machines

In the world of construction and architecture, roofing is a critical component that significantly contributes to the durability and aesthetic appeal of a building. Among the various types of roofing systems available, standing seam roofing has gained immense popularity, particularly in residential and commercial sectors. To manufacture high-quality standing seam roofs, advanced technology is necessary – and that's where standing seam roofing machines come into play.

Understanding Standing Seam Roofing

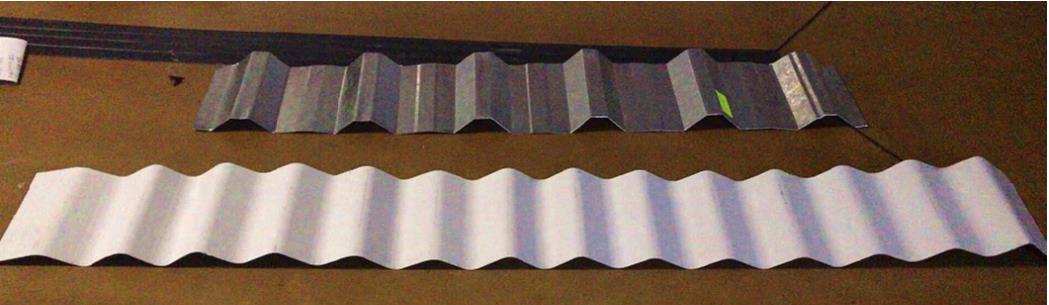

Standing seam roofing consists of vertical panels that are interlocked at the seams, which are raised above the plane of the roofing material. This design creates a distinctive visual appeal while also providing functional benefits, such as superior water shedding capabilities and enhanced durability. Standing seam roofs are typically made from metal materials, including steel, aluminum, and copper. The sleek lines and modern aesthetic have made this type of roofing increasingly sought after, especially in contemporary architectural designs.

The Role of Standing Seam Roofing Machines

Standing seam roofing machines are specialized equipment designed to manufacture the metal panels required for this roofing system. These machines have revolutionized the way roofing materials are produced and have made it easier for manufacturers to meet the increasing demand for standing seam roofs. They are equipped with cutting-edge technology that allows for precision fabrication, providing consistency and quality in the finished product.

The machines typically perform several key functions, including cutting, bending, and forming metal sheets into the desired panel shape. Modern standing seam roofing machines are capable of producing panels of various widths and lengths, accommodating the specific requirements of different projects. The efficiency of these machines reduces production time, which ultimately lowers costs and increases profitability for manufacturers.

Advancements in Technology

standing seam roofing machine factory

Over the years, standing seam roofing machines have undergone significant advancements. The introduction of computer numerical control (CNC) technology has enabled manufacturers to achieve unprecedented accuracy in their productions. These automated systems allow for programmable settings, which means that manufacturers can create unique panel designs to suit specific architectural styles quickly.

Furthermore, many modern machines incorporate features like automatic material handling, which streamlines the production process. This not only enhances efficiency but also minimizes the risk of errors during the manufacturing process. Additionally, innovations in mobile standing seam machines have made it possible for contractors to fabricate panels on-site, further reducing delivery times and costs while ensuring a perfect fit.

Environmental Considerations

Sustainability is a growing concern in the construction industry, and standing seam roofing machines play a role in promoting eco-friendly practices. Metal roofs are known for their longevity and recyclability, and advancements in manufacturing processes have further enhanced their environmental benefits. The production of standing seam roofs can now be done using recycled materials, and the energy required for manufacturing has been significantly reduced with modern technologies.

Furthermore, standing seam roofs are often more energy-efficient than traditional roofing systems. They can be designed to accommodate reflective coatings that minimize heat absorption, thus reducing energy costs for heating and cooling buildings. This aligns with the increasing demand for sustainable construction practices and energy-efficient designs.

Conclusion

In conclusion, standing seam roofing machines are pivotal in the construction and manufacturing of one of the most sought-after roofing systems today. Their evolution has been marked by technological advancements that have enhanced production efficiency, precision, and sustainability. As the demand for aesthetically pleasing and durable roofing solutions continues to grow, the importance of standing seam roofing machines in the industry will undoubtedly increase. By streamlining production processes and promoting environmentally friendly practices, these machines are not only transforming the way roofs are made but also paving the way for a more sustainable future in construction. Whether for residential homes or commercial buildings, the role of standing seam roofing and the machines that produce them cannot be understated.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025