standing seam roofing machine

Standing Seam Roofing Machine Revolutionizing Roofing Systems

Standing seam roofing systems have gained immense popularity in recent years, primarily due to their durability, energy efficiency, and aesthetic appeal. At the heart of this innovative roofing technology is the standing seam roofing machine, a specialized tool designed for the precise fabrication and installation of standing seam metal roofs.

Introduction to Standing Seam Roofing

Standing seam roofs are characterized by their vertical seams, which are raised above the flat sections of the roof. This design not only enhances the visual appeal of a building but also provides excellent weather resistance. The seams are typically sealed, preventing water penetration, making this type of roofing ideal for areas prone to heavy rainfall or snow. Additionally, standing seam roofs are often made from materials like aluminum, steel, or copper, which can withstand harsh weather conditions while requiring minimal maintenance.

Importance of the Standing Seam Roofing Machine

The standing seam roofing machine plays a crucial role in the efficiency and effectiveness of the installation process. This machine is capable of creating continuous lengths of standing seam panels on-site, which significantly reduces labor costs and material waste. By eliminating the need for pre-cut panels and onsite seams, roofing contractors can achieve a cleaner and more professional finish.

Key Features of the Standing Seam Roofing Machine

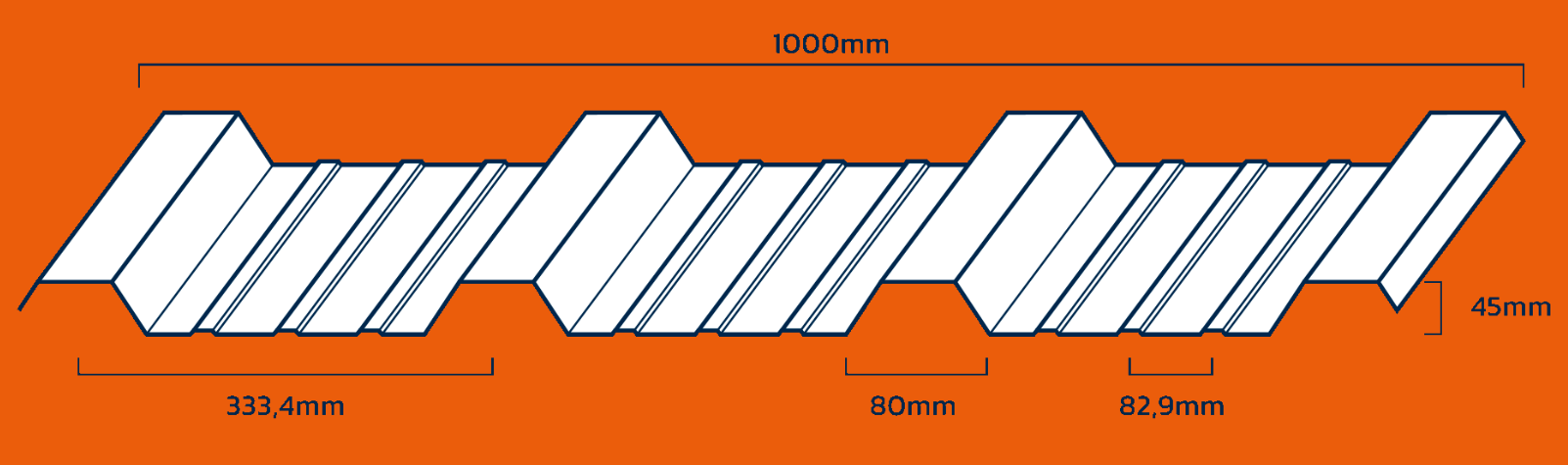

1. Versatility Modern standing seam roofing machines can accommodate a wide range of material thicknesses and profiles. This versatility allows contractors to customize the roofing system to meet specific design and structural requirements.

2. Precision Engineering These machines are engineered for precision. They ensure that each panel is cut, formed, and crimped to exact specifications, which not only enhances the roof's aesthetic but also ensures a tight fit that minimizes the risk of leaks.

standing seam roofing machine

3. Ease of Use Many standing seam roofing machines are designed with user-friendly interfaces, making them accessible even to those who may not have extensive experience with metal roofing. This feature can help reduce the learning curve for new operators.

4. Portability Many machines are designed to be portable, allowing them to be easily transported to various job sites. This portability ensures that contractors can operate efficiently, regardless of the location.

5. Durability and Reliability Given the outdoor environments in which they are often used, standing seam roofing machines are built to withstand tough conditions. Their robust construction ensures longevity and reliability over time.

The Impact on the Roofing Industry

The introduction of standing seam roofing machines has transformed the roofing industry. Contractors are now able to complete projects faster while maintaining high standards of quality. The ability to produce custom panels on-site allows for greater design flexibility, enabling home and building owners to achieve their desired look without compromise.

Additionally, the increased efficiency and precision have led to enhanced customer satisfaction. With a more secure and aesthetically pleasing roofing system, homeowners can feel confident in their investment.

Conclusion

Standing seam roofing machines represent a significant advancement in roofing technology. Their versatility, precision, and ease of use make them indispensable for contractors looking to capitalize on the growing demand for standing seam roofing systems. As technology continues to evolve, we can expect further innovations in roofing machinery that will enhance efficiency and sustainability in the construction industry. For those in the roofing profession, investing in a standing seam roofing machine is not just a choice; it’s a commitment to quality, reliability, and excellence in service.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025