standing seam roll forming machine manufacturers

Standing Seam Roll Forming Machine Manufacturers An Overview

In the evolving landscape of the manufacturing industry, standing seam roll forming machines have emerged as a critical technology for producing high-quality metal roofing and wall panels. These machines are specifically designed to create standing seam profiles that are known for their durability, aesthetic appeal, and weather-resistant properties. As the demand for sustainable and energy-efficient building materials continues to rise, the role of standing seam roll forming machine manufacturers becomes increasingly significant.

What is a Standing Seam Roll Forming Machine?

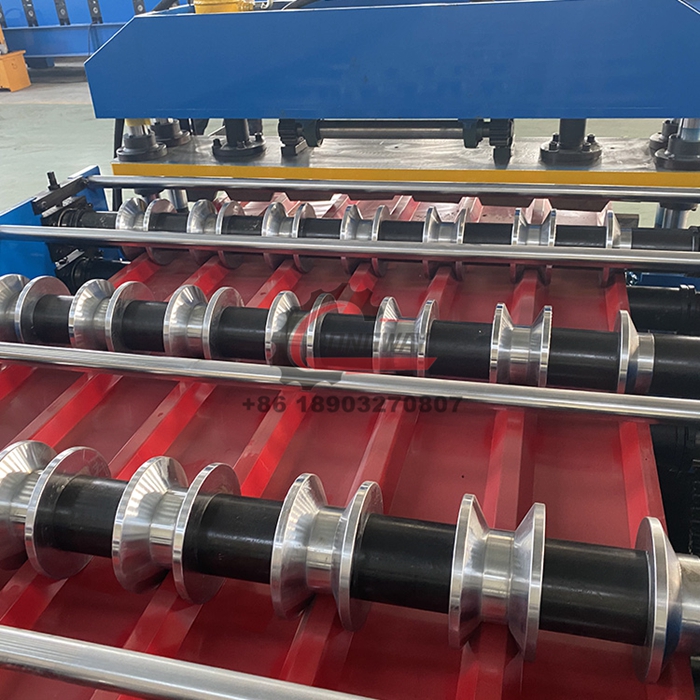

A standing seam roll forming machine is an advanced piece of equipment used to produce seamless metal panels that interlock at the edges. These machines operate on the principle of continuous roll forming where metal sheets are fed through a series of rollers to be shaped into the desired profile. The final product—standing seam panels—are widely used in commercial and residential roofing applications due to their ability to withstand harsh weather conditions and provide excellent thermal insulation.

The Importance of Quality Manufacturing

The effectiveness of standing seam roll forming machines hinges on precision engineering and quality manufacturing. Manufacturers must utilize high-grade materials and adhere to stringent quality control processes to ensure that their machines can deliver consistent results. Key aspects to consider when evaluating manufacturers include

1. Technology The adoption of advanced technologies such as computer numerical control (CNC) and automation can significantly enhance the efficiency and accuracy of roll forming machines. Manufacturers that invest in cutting-edge technology can produce complex profiles with minimal waste.

2. Customization Each project has unique specifications, and the ability to customize machines to meet these needs is essential. Reputable manufacturers often offer tailored solutions, enabling clients to produce various profiles and sizes suited to their specific requirements.

3. Durability and Maintenance A robust machine that requires minimal repairs is indispensable for manufacturers focusing on reducing downtime. Companies should choose manufacturers known for producing durable machinery and offering comprehensive maintenance support.

standing seam roll forming machine manufacturers

4. After-Sales Support The relationship between the manufacturer and the client does not end with the sale. Manufacturers that provide exceptional after-sales support—including training, troubleshooting, and spare parts—tend to foster long-term partnerships with their clients.

Notable Manufacturers in the Industry

The standing seam roll forming machine market is competitive, with several manufacturers standing out for their reliability and innovation. Here are a few notable names in the industry

1. Metform Known for its high-quality roll forming machines, Metform combines innovation with customization to meet various client needs. Their standing seam machines are recognized for their advanced technology and precision.

2. B&K Metal Fabrication This manufacturer specializes in producing roll forming machines that are user-friendly and highly efficient. Their focus on customer satisfaction and product reliability makes them a preferred choice for many.

3. Hekimoglu Operating on an international scale, Hekimoglu offers a range of standing seam roll forming machines recognized for their performance and durability. They emphasize sustainable practices in their manufacturing processes.

4. Schlebach Based in Germany, Schlebach is well-respected for its engineering expertise and high-quality machines. Their standing seam roll formers are designed to meet the rigorous demands of the metalworking industry.

Conclusion

Standing seam roll forming machines play a vital role in the production of modern roofing solutions. As the architecture and construction industries continue to evolve, the manufacturers of these machines face the challenge of delivering innovative, efficient, and durable solutions. Partnering with reputable manufacturers ensures that businesses can produce high-quality, long-lasting standing seam panels that meet the needs of today’s discerning clients. Investing in a reliable roll forming machine is not just a purchase; it’s a strategic decision that can significantly impact a company’s productivity and bottom line. As the demand for energy-efficient and aesthetically pleasing building materials grows, the role of standing seam roll forming machine manufacturers will undoubtedly expand, paving the way for new opportunities in this dynamic sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025