standing seam profiling machine factory

Understanding Standing Seam Profiling Machines A Brief Overview

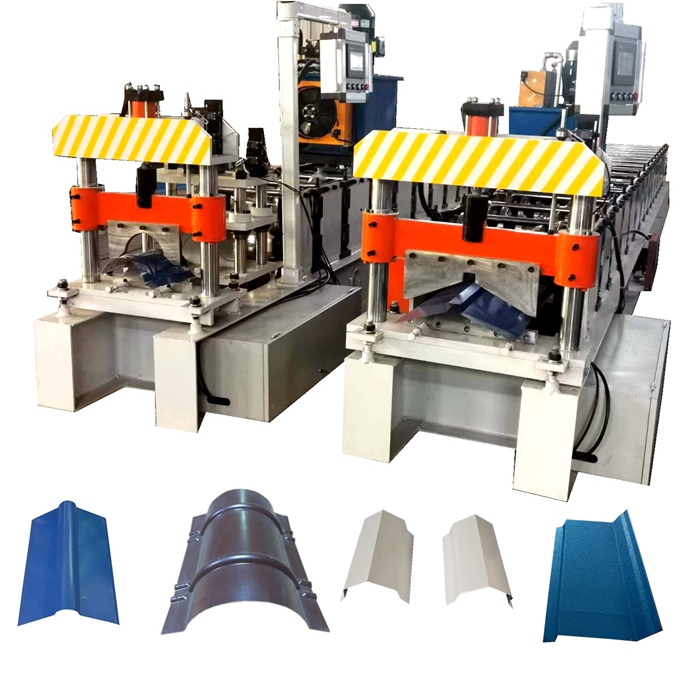

Standing seam roofing systems have gained popularity in both commercial and residential constructions due to their durability, aesthetic appeal, and superior weather resistance. At the heart of this roofing technology are standing seam profiling machines, specialized equipment designed to produce the distinctive panels required for these roofs. This article delves into the importance of these machines and their function in the manufacturing process.

A standing seam profiling machine is engineered to create metal panels with interlocking seams that rise above the plane of the roof. These seams not only improve the structural integrity of the roof but also ensure effective water drainage, making them an ideal choice for locations prone to heavy rainfall or snowfall. The machines come in various configurations, including manual, semi-automatic, and fully automatic systems, catering to diverse production needs.

The process begins with metal coils, usually made of steel or aluminum, which are fed into the machine. The profiling machine shapes the coils into panels using a series of rollers that form the desired profile. For standing seam roofs, the machine typically creates ribs along the length of the panel, which are essential for the interlocking mechanism. The precision in shaping not only affects the aesthetic quality of the final product but also influences its performance and longevity.

standing seam profiling machine factory

Modern standing seam profiling machines are equipped with advanced technology, including programmable controls and automated features that enhance efficiency and accuracy. This automation enables manufacturers to produce panels of varying lengths and widths while maintaining consistent quality. Additionally, some machines offer the capability to perform multiple profiles, allowing for greater versatility in production and customization options for clients.

Investment in a standing seam profiling machine is a strategic move for manufacturers looking to expand their product offerings in the metal roofing sector. With the growing demand for environmentally sustainable building solutions, metal roofing provides an excellent option due to its recyclability and energy efficiency. Profiling machines play a crucial role in meeting this demand by enabling high-quality production that aligns with green building practices.

Furthermore, with increasing competition in the roofing industry, manufacturers must focus on reducing lead times and maximizing output. The efficiency of a standing seam profiling machine can significantly impact a company’s ability to meet tight deadlines without compromising on quality. By leveraging advanced manufacturing technologies, companies can enhance their market position while satisfying customer needs for reliable and attractive roofing solutions.

In conclusion, standing seam profiling machines are vital in producing high-quality roofing panels that contribute to the architectural and functional integrity of buildings. Their advanced features, combined with the growing market for metal roofing, make them an indispensable asset for manufacturers aiming to thrive in the construction industry. As demand continues to rise, so too will the importance of these innovative machines in shaping the future of roofing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025