Leading Manufacturer of High-Quality Standing Seam Panel Production Machines

Standing Seam Panel Machine Manufacturers An Overview of Industry Leaders and Innovations

Standing seam metal roofs have become increasingly popular due to their durability, weather resistance, and aesthetic appeal. As a result, the demand for standing seam panel machines has surged, leading to several manufacturers emerging as leaders in this specialized field. This article provides a comprehensive overview of the standing seam panel machine market, focusing on key manufacturers, the technology behind the machines, and future trends shaping the industry.

Understanding Standing Seam Panel Machines

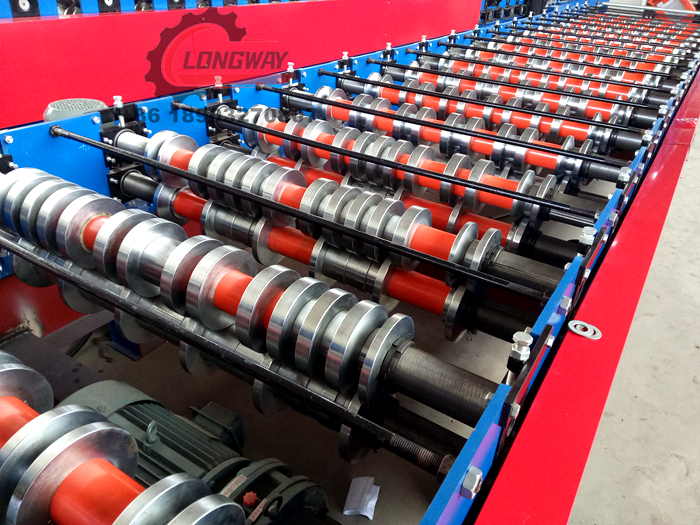

Standing seam panel machines are specialized equipment designed to fabricate metal roofing panels with raised seams. These machines utilize advanced technology to roll-form metal sheets into panels that interlock at the seams. The result is a weather-tight seal that provides enhanced protection against wind and rain. Manufacturers of these machines employ various steel and metal substrates, allowing for customization based on project requirements.

Key Manufacturers in the Industry

1. SMP Machinery Known for its high-quality rolling machines, SMP Machinery has established itself as a cornerstone in the standing seam panel machine industry. Their machines are designed for high efficiency and precision, capable of handling various metal gauges. SMP’s commitment to innovation includes the integration of smart technology, enabling real-time monitoring and adjustments during the production process.

2. Baileigh Industrial Baileigh Industrial focuses on providing robust and reliable metalworking machinery, including standing seam panel machines. Their equipment is widely recognized for its durability, making it ideal for both small and large-scale operations. Baileigh’s advanced features, such as programmable controls and variable-speed options, offer users greater flexibility in production.

3. Formtek Formtek is another major player in the standing seam panel machine market, with a strong focus on customization. They offer machines that can produce a variety of panel widths and profiles, catering to the diverse needs of contractors and manufacturers. Formtek’s commitment to quality is evident in their rigorous testing processes and exceptional customer support.

4. Metform Metform has garnered a reputation for its high-performance standing seam panel machines that prioritize speed and precision. Their innovative designs allow for quick changeovers between different panel profiles, which is essential for manufacturers looking to maximize productivity. Metform also emphasizes energy efficiency in its machinery, allowing users to reduce operational costs over time.

standing seam panel machine manufacturer

Technological Advancements

The standing seam panel machine industry has witnessed remarkable technological advancements in recent years. Many manufacturers are integrating automation and smart technology into their machines. Features such as computer numerical control (CNC) systems enable precise panel fabrication with minimal human intervention. Moreover, the incorporation of IoT (Internet of Things) technology facilitates real-time data collection, which helps optimize production processes and predict maintenance needs.

Another significant trend is the shift towards sustainability. Manufacturers are increasingly focusing on energy-efficient machines that use less power during operation and generate less waste. This is not only beneficial for the environment but also helps companies reduce costs in the long run.

Future Trends

As the construction industry continues to evolve, the demand for standing seam panel machines is expected to rise. Factors such as increased awareness of energy-efficient building practices and the growing popularity of metal roofing in residential and commercial projects will drive this demand. Additionally, the ongoing advancements in materials science, including the development of lighter and stronger metals, will likely contribute to the evolution of standing seam panel machines.

Moreover, manufacturers that prioritize customer feedback and adapt their products to meet changing market demands will thrive. Customization, speed, and efficiency will remain pivotal in providing quality solutions that meet the needs of contractors and builders.

Conclusion

Standing seam panel machines are essential in the evolving landscape of metal roofing. With several leading manufacturers at the forefront, the industry is poised for continued growth and innovation. As technology advances and sustainability becomes more critical, the standing seam panel machine market is likely to see exciting developments that will reshape how roofing solutions are produced and installed. Whether you are a contractor, manufacturer, or builder, staying informed about these advancements is key to success in the competitive construction arena.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025