standing seam metal roof machine for sale companies

Understanding Standing Seam Metal Roof Machines and Their Importance in the Roofing Industry

Standing seam metal roofs have gained immense popularity in both residential and commercial construction due to their durability, energy efficiency, and aesthetic appeal. As more builders and homeowners recognize the benefits of this roofing style, the demand for standing seam metal roof machines is on the rise. This article delves into the significance of these machines, the key players in the market, and what to consider when looking for one.

What are Standing Seam Metal Roof Machines?

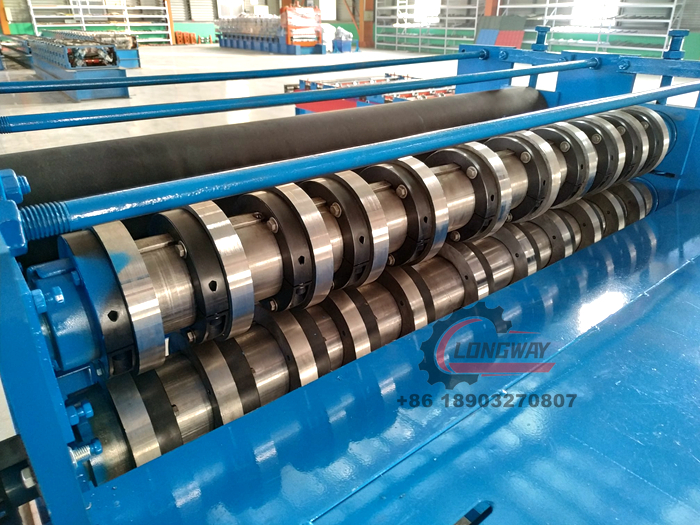

Standing seam metal roof machines are specialized equipment designed to fabricate metal panels that are used in standing seam roofing systems. These machines can form, cut, and sometimes even roll the metal sheets into the desired profile, allowing for seamless installation. They are essential in ensuring that panels are correctly shaped, which is critical in achieving water resistance and structural integrity.

Advantages of Standing Seam Metal Roofs

Before exploring the machines further, it’s essential to understand why standing seam metal roofs have become a preferred choice. These roofs provide superior weather resistance, which is crucial in areas prone to harsh climates. Additionally, they have a sleek, modern look that enhances aesthetic appeal. Standing seam roofs also reflect solar heat, leading to energy savings, making them an environmentally friendly choice.

Key Players in the Market

Several companies manufacture standing seam metal roof machines, each offering a range of models suitable for different scales of production. Established manufacturers such as Olsen Manufacturing, RoboFold, and Metform are known for their innovative designs and reliability. Additionally, many companies offer customizable options to satisfy niche market needs. When choosing a machine, buyers should evaluate their production capacity, the type of metals they wish to work with, and the level of automation they require.

Factors to Consider When Purchasing a Standing Seam Metal Roof Machine

standing seam metal roof machine for sale companies

1. Production Capacity Consider how many panels you need to produce daily or weekly. This will help determine whether a small, standalone machine will suffice or if a full production line is necessary.

2. Material Compatibility Ensure the machine is compatible with the types of metal you intend to use. Common materials include aluminum, steel, and copper, each requiring different handling.

3. Automation Level Fully automated machines can significantly increase efficiency but may come with a higher upfront cost. Semi-automated or manual machines could be more economical if you're just starting or working on smaller projects.

4. Investment and Budgeting Determine your budget not just for the initial machine purchase but also consider operational costs, maintenance, and potential upgrades in the future.

5. Supplier Reputation Partner with reputable suppliers to ensure that you receive quality after-sales support, including maintenance, repairs, and spare parts.

6. Training and Support Investing in a machine also means investing in the training of your staff to operate it effectively. Check whether the manufacturer offers training as part of the purchase package.

Conclusion

As the construction industry continues to evolve, standing seam metal roofs have carved out a significant niche due to their numerous benefits. The machines that facilitate their production play an essential role in meeting this growing demand. By considering factors such as production capacity, material compatibility, automation level, and supplier reputation, builders can make informed decisions about investing in standing seam metal roof machines. In turn, this will enhance their operations and ensure they deliver quality roofing solutions that stand the test of time. Investing in the right machinery not only adds efficiency to production but also reflects positively on the overall quality of construction projects.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025