standing seam metal machine manufacturer

Standing Seam Metal Machine Manufacturers Revolutionizing Metal Roofing Solutions

The construction industry has seen significant advancements over the years, particularly in roofing technology. Among these innovations, standing seam metal roofing has emerged as a favored choice among architects, builders, and homeowners alike. This trend has given rise to a specialized sector within manufacturing, specifically focusing on standing seam metal machines. These manufacturers are crucial players in the metalworking industry, providing essential tools and equipment that facilitate the installation of this efficient roofing system.

Understanding Standing Seam Metal Roofing

Before diving into the realm of standing seam metal machines, it’s important to understand what standing seam metal roofing entails. This type of roofing consists of interlocking metal panels that are raised at the seams, providing a sleek and modern aesthetic. The vertical seams that are elevated help to manage water flow, significantly reducing the chances of leaks, which is critical in ensuring the longevity of a building. This roofing system is often made from materials such as aluminum, steel, or copper, all of which offer durability and resistance to extreme weather conditions.

The Role of Standing Seam Metal Machines

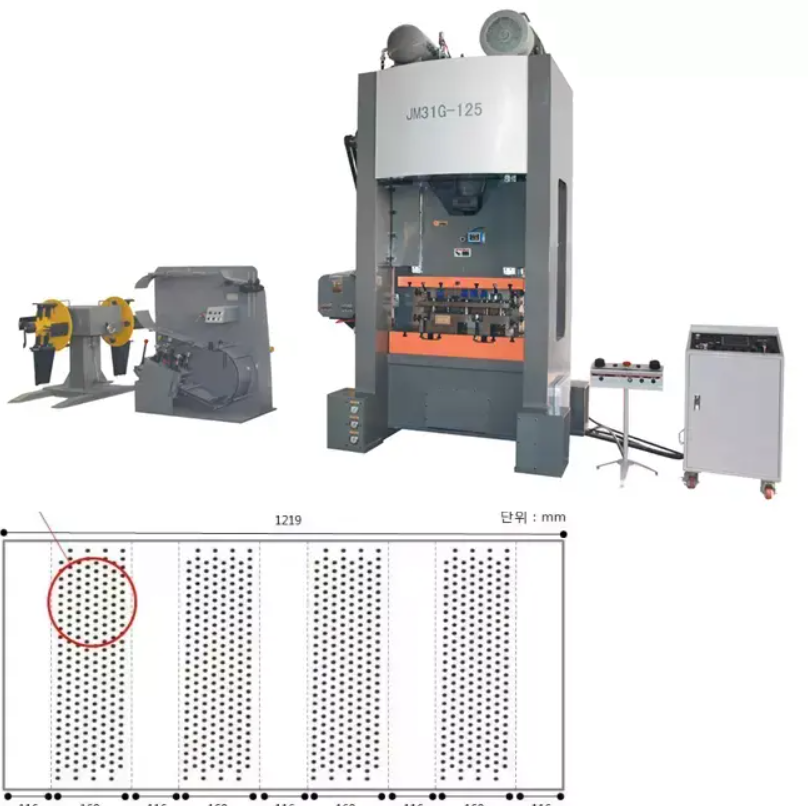

Standing seam metal machines are specialized equipment designed to produce and install the panels required for this type of roofing. These machines have evolved in response to the growing demand for metal roofing systems. The main functions of these machines include cutting, shaping, and forming metal sheets into precise dimensions. Manufacturers of these machines focus on enhancing efficiency, accuracy, and ease of use.

The primary categories of standing seam machines include roll formers, which create the panels from flat sheets of metal, and seamers, which are used to lock the seams together securely. Advanced models may also incorporate features such as automated controls, which allow for greater precision and reduce labor costs. The market for standing seam metal machines is incredibly diverse, with manufacturers constantly innovating to produce more effective and user-friendly equipment.

Choosing the Right Machine Manufacturer

standing seam metal machine manufacturer

Selecting a reputable manufacturer is paramount for anyone looking to invest in a standing seam metal machine. Quality is key, as the reliability of the machines can significantly impact productivity and the final product's quality. A good manufacturer will offer not only high-quality machines but also excellent customer service, training, and support to ensure that users can operate their equipment efficiently.

When researching potential manufacturers, consider their experience in the industry, the range of equipment they offer, and any available warranties or service agreements. Additionally, reading customer reviews and testimonials can provide valuable insight into the reliability and performance of their machines.

The Future of Standing Seam Metal Machines

The future of standing seam metal machines appears bright, with technological advancements driving improvements in efficiency and sustainability. As the construction industry shifts towards more environmentally friendly practices, manufacturers are integrating eco-friendly materials and processes into their machines. This might include the use of recycled metals and energy-efficient production methodologies.

Moreover, as buildings evolve into more complex structures, standing seam metal machines will likely incorporate features that enhance their flexibility and adaptability. Innovations such as robotic automation and artificial intelligence may play a pivotal role in shaping the future landscape of metal roofing machinery.

Conclusion

Standing seam metal machines are at the forefront of a crucial trend in the construction industry that emphasizes durability, efficiency, and aesthetic appeal. As manufacturers continue to innovate and improve their offerings, they are not only enhancing the capabilities of metal roofing systems but also contributing to the overall sustainability of the construction sector. For builders and contractors, investing in high-quality standing seam metal machines translates into better roofing solutions and ultimately more satisfied customers. As we look ahead, the synergy between technology and manufacturing in this domain promises to revolutionize the way we think about roofing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025