Innovative Mechanical Seaming Solutions for Standing Seam Roofing Systems

The Advancements in Standing Seam Mechanical Seamers Transforming the Metal Roofing Industry

In the realm of metal roofing, the efficiency and durability of installation are paramount. One of the most innovative tools in this domain is the standing seam mechanical seamer. As the demand for high-quality roofing solutions continues to rise, so does the importance of utilizing advanced technology in the installation process. This article delves into the significance of standing seam mechanical seamers and how they are revolutionizing the metal roofing industry.

Understanding Standing Seam Roofing

Standing seam roofing is a type of metal roofing system characterized by vertical panels with raised seams that interlock. This design not only facilitates efficient water drainage but also enhances the durability and aesthetics of the roof. A major advantage of standing seam roofing is its ability to expand and contract with temperature fluctuations, making it ideal for various climates. However, the effectiveness of this roofing system significantly depends on the quality of installation, which is where mechanical seamers come into play.

The Role of Mechanical Seamers

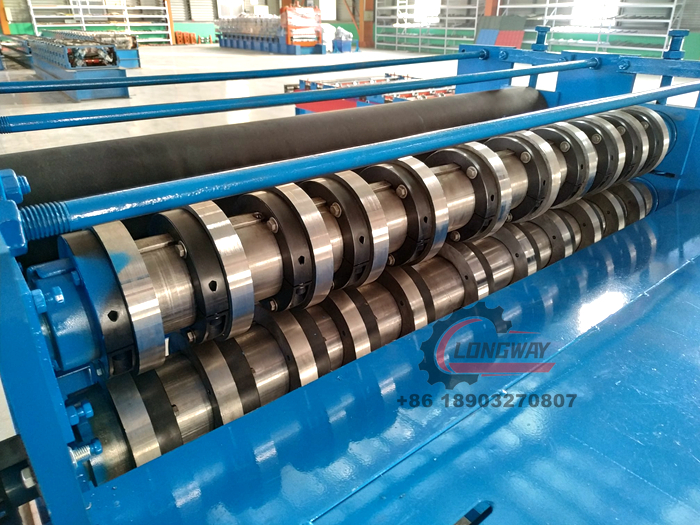

Mechanical seamers are specialized tools designed to fold and lock the seams of standing seam panels securely. This process creates a watertight seal that is essential for preventing leaks and ensuring the longevity of the roof. Mechanical seamers offer several advantages over manual seams, including increased speed, consistency, and precision.

Enhancements in Technology

Recent advancements in mechanical seamer technology have made these tools more efficient and user-friendly. Modern seamers are equipped with powerful motors and adjustable settings, allowing operators to customize the seaming process based on the specific requirements of each project. Wireless capabilities and battery-operated models have also increased portability, enabling contractors to work in various settings without being tethered to power sources.

standing seam mechanical seamer company

One of the most significant improvements is the reduction of physical strain on workers. Traditional methods often required significant manual effort, leading to fatigue and potential injuries. Mechanical seamers alleviate this concern, allowing operators to achieve high-quality seams without the physical toll. The ergonomic design of new models ensures that contractors can work more comfortably and efficiently, enhancing overall productivity.

Quality and Precision

Quality control is critical in roofing projects, and standing seam mechanical seamers address this need effectively. The precision offered by mechanical seamers ensures that seams are uniformly tight, significantly reducing the risk of leaks caused by improperly sealed joints. This consistency is essential not only for the durability of the roof but also for preserving the aesthetic appeal of metal roofing installations.

Moreover, many manufacturers have introduced features such as built-in diagnostic tools, which provide real-time feedback on seam integrity. This innovation allows contractors to address any potential issues immediately, minimizing rework and ensuring that every project meets the highest standards.

The Industry’s Shift Towards Automation

As the construction industry shifts towards automation, standing seam mechanical seamers represent a crucial step forward. The integration of automation allows for faster installation times and reduced labor costs, making projects more economically viable. Additionally, as more contractors adopt these advanced tools, the overall quality of metal roofing installations improves, benefiting homeowners and commercial property owners alike.

Conclusion

In conclusion, standing seam mechanical seamers have become indispensable in the metal roofing industry. Their ability to improve efficiency, quality, and worker safety is transforming the way roofing projects are approached. As technological advancements continue to evolve, these tools will undoubtedly play a pivotal role in shaping the future of roofing installations, ensuring that they meet the demands of durability and functionality that modern buildings require. As more contractors embrace these innovations, the standard for metal roofing installation will continue to rise, ultimately benefiting the entire industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025