Understanding the Benefits of Using a Standing Seam Mechanical Seamer for Roofing Projects

Understanding Standing Seam Mechanical Seamers An Overview

Standing seam roofs have gained immense popularity in modern architecture due to their durability, aesthetic appeal, and energy efficiency. A critical component in the installation of standing seam roofing systems is the use of a mechanical seamer. This article will delve into the significance of standing seam mechanical seamers, exploring their functionality, advantages, and considerations during installation.

What is a Standing Seam Mechanical Seamer?

A standing seam mechanical seamer is a specialized tool designed to join adjacent panels of standing seam roofing. The standing seam consists of vertical legs that interlock at the seams, creating a water-tight barrier. The mechanical seamer bends and folds the edges of the panels together, ensuring a secure and durable seam. This process can be performed either during the installation or as part of maintenance to reinforce existing seams.

How it Works

The operation of a mechanical seamer involves placing the tool over the seam of two adjacent panels and applying mechanical pressure to fold the seams together. Depending on the design of the seamer, this may involve a variety of mechanisms, including hydraulic or electric power systems. There are typically three key steps in the seaming process

1. Positioning The seamer is positioned over the seam, ensuring that the edges align perfectly. 2. Seaming The operator engages the seamer, allowing it to apply pressure and fold the seams together. This process may vary depending on the type of mechanical seamer being used, whether it's a hand-held, portable version or a larger, more industrial model.

3. Inspection After the seaming process, the seam is inspected for any gaps or irregularities. A properly sequenced seam should result in a smooth, continuous line, effectively sealing the roof against water intrusion.

Advantages of Using Mechanical Seamers

1. Durability Mechanical seamers create strong and lasting seams, which significantly reduce the risk of leaks. The precision of the folds enhances the roof's longevity, ensuring that it can withstand extreme weather conditions.

2. Efficiency Utilizing a mechanical seamer facilitates a faster installation process compared to traditional hand-seaming methods. This efficiency translates into lower labor costs and shorter project timelines.

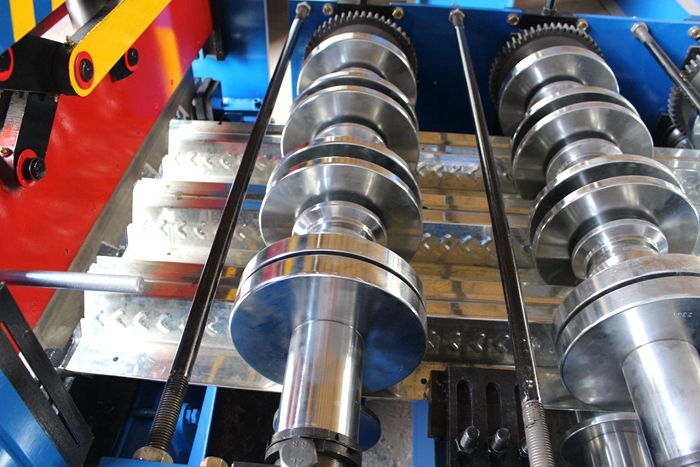

standing seam mechanical seamer

3. Consistency Mechanical seamers provide a uniform seam quality throughout the installation, reducing the likelihood of human error associated with manual seaming methods.

4. Versatility Mechanical seamers are designed to handle various types of metal roofing materials, including aluminum, steel, and copper. This versatility allows contractors to adopt a single tool for multiple projects.

Considerations During Installation

While mechanical seamers offer numerous benefits, there are several considerations to keep in mind during installation

- Training Operators should be adequately trained in the use of mechanical seamers to prevent damage to the roofing panels or seamer itself.

- Material Compatibility It is essential to select the right seamer for the specific type of metal being used, ensuring compatibility for optimal performance.

- Environmental Conditions Installation should take place in dry and moderate weather conditions to prevent complications related to temperature and moisture, which can affect the performance of the seams.

- Regular Maintenance Proper maintenance of the mechanical seamer is crucial for its longevity and effectiveness. Regular checks and servicing can prevent unanticipated breakdowns during critical installations.

Conclusion

Standing seam mechanical seamers play a vital role in the efficiency and durability of standing seam roofing systems. Their ability to create strong, uniform seams not only enhances the aesthetic appeal of a roof but also ensures long-lasting protection against the elements. As the demand for quality roofing solutions grows, understanding and utilizing the capabilities of mechanical seamers will continue to be essential for roofing professionals. By investing in the right tools and training, contractors can provide superior roofing solutions that stand the test of time.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025