standing seam machine price factory

Understanding the Pricing of Standing Seam Machine from Factories

In recent years, the construction industry has seen a growing demand for metal roofing systems, particularly standing seam roofs. They are known for their durability, energy efficiency, and aesthetic appeal. Consequently, the demand for standing seam machines, which are used in the production and installation of such roofing systems, has also risen. This article explores various factors that influence the pricing of standing seam machines from factories.

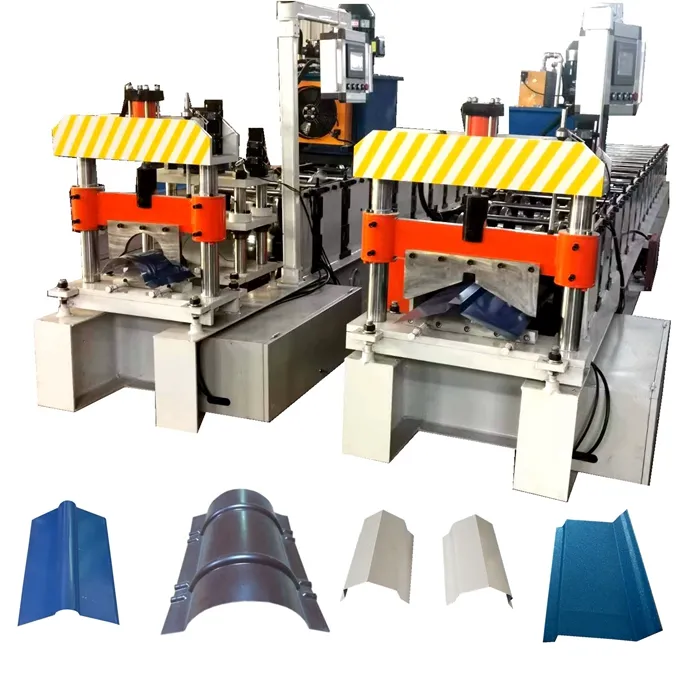

1. Types of Standing Seam Machines

Standing seam machines come in various types, each designed to cater to different needs and budgets. From portable machines used for small-scale projects to larger, heavy-duty models for industrial usage, the price can vary significantly. Basic models might start at lower price points, while advanced machines equipped with numerous features, such as automated cutting and forming capabilities, can command much higher prices.

2. Features and Specifications

The specifications of the standing seam machine play a crucial role in determining its price. Machines designed to produce a wider range of profiles, with higher production speeds, and enhanced precision tend to be more expensive. Automatic vs. manual operation is another consideration; automatic machines often result in higher labor efficiency but come with a substantial upfront investment. Additionally, features such as adjustable roll forming speeds, quality of materials used, and the inclusion of technology for easier operation also influence pricing.

The geographical location of a factory influences the price of standing seam machines. Countries with lower labor costs can offer machines at a more competitive price. However, buyers must be cautious; lower initial costs might come at the expense of quality. Machines produced in regions with strict manufacturing standards and higher-quality materials may be pricier but are often more reliable in the long term.

standing seam machine price factory

4. Supplier Reputation and Service

The reputation of the manufacturer's brand can significantly influence the price. Established suppliers with a proven track record of quality and after-sales service often charge a premium. Buyers are more likely to invest in machines from reputable brands to ensure they receive support, warranties, and maintenance services that come with the purchase. Investing in a standing seam machine from a reliable supplier can prevent future problems and maintenance costs, making it a worthwhile consideration.

5. Customization Options

Customization can lead to a significant increase in the cost of standing seam machines. Businesses may prefer machines tailored to their specific requirements, including size, profiles, and features. This bespoke approach often results in a higher price tag. However, the benefits of having a machine designed to meet precise specifications can lead to increased productivity and efficiency, potentially offsetting the initial costs.

6. Market Trends and Demand

Market trends also play a significant role in influencing the pricing of standing seam machines. When demand for roofing materials rises, so do the prices of the machinery required to produce them. Furthermore, fluctuations in raw material prices, such as steel and aluminum, can lead to changes in machine pricing. Keeping abreast of market conditions can help buyers time their purchases for the best possible prices.

Conclusion

Purchasing a standing seam machine is a significant investment that requires careful consideration of various factors. From machine types and specifications to manufacturer reputation and market trends, each element plays a crucial role in determining the final price. While it may be tempting to opt for the lowest-priced machine, it’s essential to consider the long-term value, durability, and efficiencies offered by higher-quality options. By understanding these dynamics, businesses can make informed decisions that align with their production needs and financial constraints, ultimately leading to profitable investments in the growing field of metal roofing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025