standing seaming roof panel roll forming machine

The Standing Seam Roof Panel Roll Forming Machine An Essential Tool for Modern Roofing Solutions

In the ever-evolving sector of construction and architecture, the demand for efficient and durable roofing solutions has surged. One of the standout innovations that cater to this requirement is the standing seam roof panel roll forming machine. This advanced piece of equipment plays a pivotal role in the production of metal roofing panels that are not only aesthetically pleasing but also extremely functional.

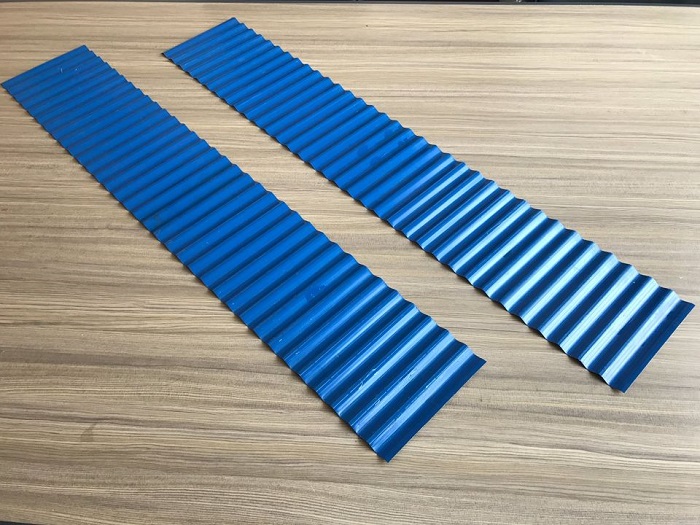

Standing seam roofs are characterized by their vertical legs and flat spaces in between, creating raised seams that can effectively channel water away from the roof. The design promotes both durability and energy efficiency, making it a preferred option among architects and builders. The roll forming machine is instrumental in this process, providing an automated method for creating these panels with precision.

The operation of a standing seam roof panel roll forming machine begins with the feeding of metal coils into the machine

. These coils are typically made from high-quality materials such as galvanized steel or aluminum, known for their strength and resistance to corrosion. As the coil is fed into the machine, rollers shape the metal into the desired profile, creating interlocking seams that enhance the roof's weatherproofing capabilities.One of the significant advantages of using a roll forming machine is its ability to produce custom lengths of roofing panels. This flexibility reduces waste and labor costs, as the panels can be generated on-site and tailored to specific project requirements. Moreover, the precision of the manufacturing process ensures that each panel fits seamlessly with others, essential for maintaining the integrity of the roofing system.

standing seaming roof panel roll forming machine

Another notable feature of modern standing seam roof panel roll forming machines is their ability to produce a variety of panel profiles. Different architectural styles may call for unique seam configurations, and these machines can accommodate such variations without sacrificing efficiency. This versatility positions roll forming as a vital asset for contractors who need to adapt to diverse project demands.

In addition to versatility and customizability, standing seam roof panel roll forming machines are engineered for speed and efficiency. With the capability to produce large volumes of panels in a short timeframe, these machines help meet tight deadlines commonly faced by contractors. As a result, they contribute to faster project completions, ultimately improving customer satisfaction.

The significance of standing seam roofs goes beyond aesthetics and functionality; they also play a role in environmental sustainability. Metal roofs are highly recyclable and can significantly reduce energy costs when properly installed. By utilizing a roll forming machine, manufacturers can produce high-quality roofing systems that support eco-friendly building practices.

In conclusion, the standing seam roof panel roll forming machine exemplifies the intersection of innovation and practicality in modern roofing solutions. Its ability to produce customized, durable, and energy-efficient roofing panels positions it as an indispensable tool in the construction industry. As the demand for sustainable and durable roofing continues to grow, investing in such machinery will undoubtedly remain a wise choice for manufacturers and contractors alike, paving the way for a more resilient future in architecture.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025