standing seam forming machine

The Standing Seam Forming Machine An Overview

In the realm of modern construction, the standing seam roof system has gained significant popularity due to its sleek appearance and durability. Essential to the production of these roofs is the standing seam forming machine, a specialized tool that streamlines the manufacturing process and ensures high-quality results.

Understanding Standing Seam Roofing

Standing seam roofs are characterized by raised seams that interlock different panels, providing a waterproof solution that is also aesthetically pleasing. These panels are typically made from metal, such as aluminum, steel, or copper, making them resistant to harsh weather conditions and corrosion. The seamless integration of these panels results in a clean, uniform look, appealing to architects and builders alike.

The Importance of the Forming Machine

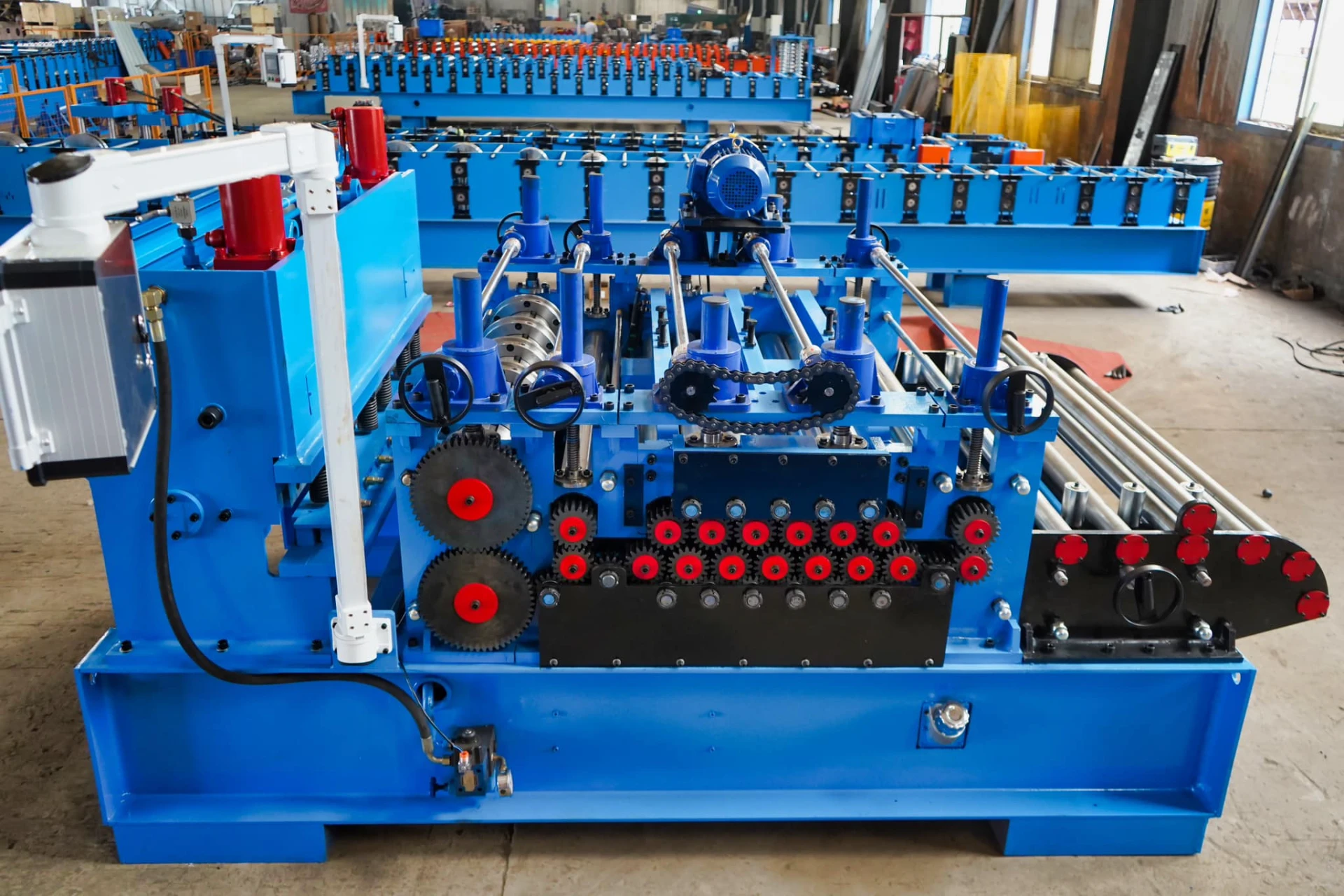

The standing seam forming machine plays a crucial role in the fabrication of these roofing panels. This machine is designed to convert flat metal sheets into tightly locked, watertight panels through a series of precise forming processes. The key advantage of using a standing seam forming machine is its efficiency; manufacturers can generate large quantities of panels in a fraction of the time it would take to create them manually.

How It Works

The standing seam forming machine operates through a multi-step procedure. Initially, flat metal sheets are fed into the machine, which uses rollers to progressively shape the metal. These rollers bend and fold the metal to create the desired seam profile, which is essential for interlocking the panels securely. The precision of the machinery ensures that each panel is consistent in dimensions and mold, which is vital for proper installations.

Moreover, some advanced models include automatic features that enhance usability, such as digital controls and integration with software for design customization. This allows manufacturers to adjust specifications quickly based on project requirements without extensive downtime. The incorporation of technology into these machines not only improves efficiency but also significantly reduces the margin for error in panel production.

standing seam forming machine

Advantages of Using a Standing Seam Forming Machine

Utilizing a standing seam forming machine offers several benefits

1. Efficiency The automation and speed of the machine reduce labor costs and time needed for production, allowing manufacturers to meet tight deadlines and increasing output.

2. Quality Control Consistent production of high-quality panels helps maintain the integrity of the roofing system. Unlike manual processes, the machine reduces variances that can lead to potential failures or leaks in seams.

3. Versatility These machines can be designed to form panels of different widths and seam styles, catering to a wide range of architectural needs and preferences.

4. Durability Standing seam roofs manufactured with these machines are designed to withstand extreme weather conditions, providing longevity and sustained visual appeal, which ultimately benefits property owners.

Conclusion

The standing seam forming machine is an essential component in the modern building materials industry. By enhancing the efficiency, consistency, and quality of standing seam panels, these machines enable manufacturers to meet the growing demand for durable and attractive roofing solutions. As technology continues to advance, we can expect further innovations in these machines, further revolutionizing the way standing seam roofs are produced and installed. In adopting such machinery, companies position themselves for success in a competitive market, ensuring they can deliver high-quality results to their clients while keeping pace with evolving building trends.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025