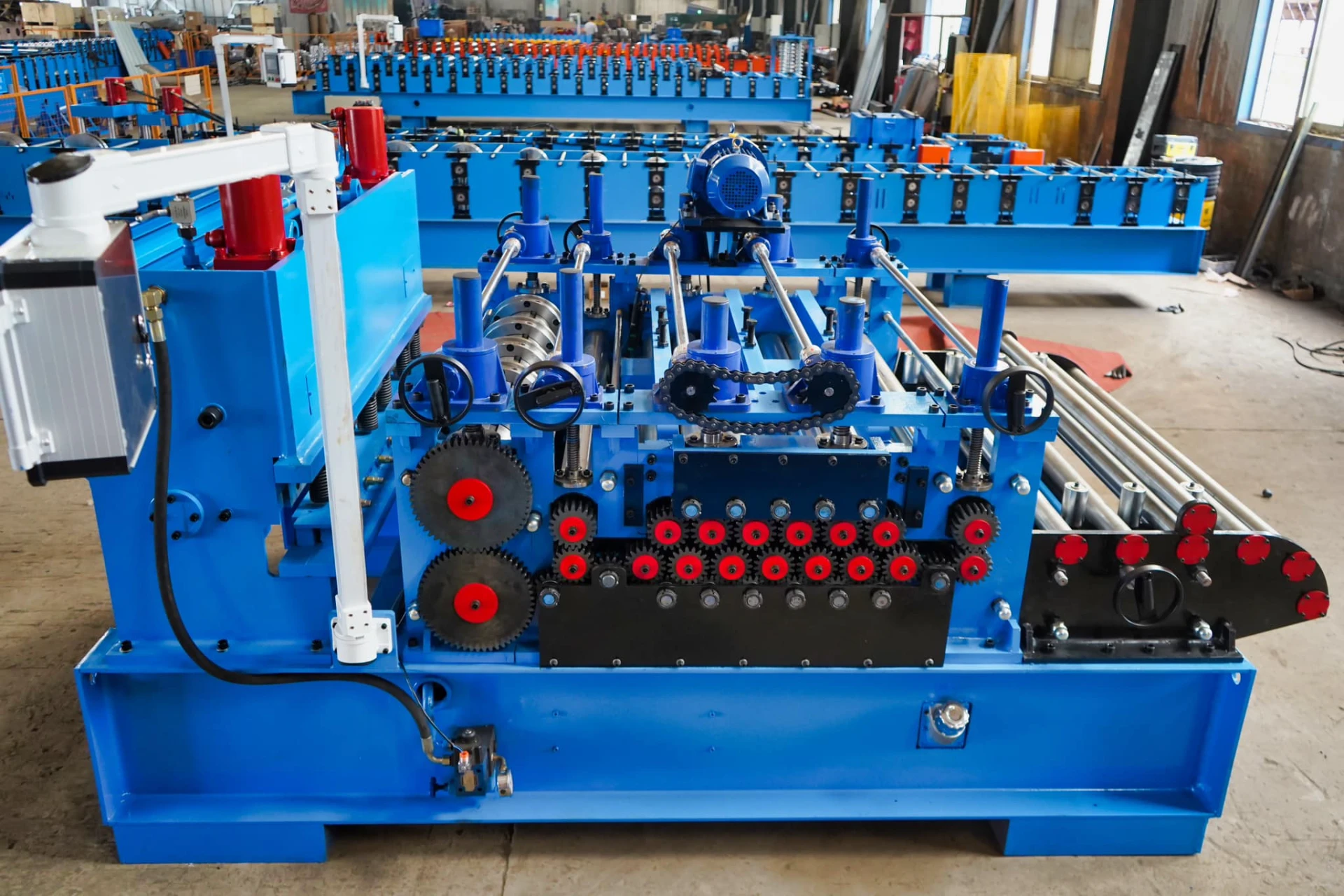

stainless steel coil slitting machine

Exploring the Advantages of Stainless Steel Coil Slitting Machines

In the modern manufacturing landscape, efficiency and precision are key components in the production process. One of the essential tools in the metalworking industry is the stainless steel coil slitting machine. This advanced piece of equipment is designed to cut large coils of stainless steel into narrower strips, enabling manufacturers to meet specific requirements for various applications.

Stainless steel is favored for its corrosion resistance, strength, and aesthetic appeal, making it a popular choice across multiple industries, including automotive, construction, and food processing

. The importance of precision in processing this material cannot be overstated, and this is where the stainless steel coil slitting machine proves invaluable.These machines are engineered to handle coils of different thicknesses and widths, allowing for versatility in production. The slitting process involves feeding the stainless steel coil through a series of blades that accurately cut the material to the desired specifications. This method not only ensures a clean cut but also minimizes waste, which is a critical consideration in today’s environmentally conscious manufacturing practices.

stainless steel coil slitting machine

One of the key advantages of using a stainless steel coil slitting machine is the significant reduction in processing time. Compared to manual cutting methods, these machines can operate at high speeds, producing high volumes of finished strips in a fraction of the time. This efficiency translates to lower labor costs and increased productivity, allowing manufacturers to respond swiftly to market demands.

Moreover, modern slitting machines are equipped with advanced technology that enhances precision and control. Features such as adjustable blade spacing, automated feeding systems, and digital monitoring ensure that manufacturers can achieve consistent results. This reliability is crucial for businesses that require uniformity in their products, as it meets customer expectations and maintains quality standards.

Maintenance is also facilitated by these state-of-the-art machines. With proper care, stainless steel coil slitting machines can provide years of uninterrupted service. Regular maintenance routines, which include blade replacement and system checks, keep the machinery operating efficiently and minimize downtime.

In conclusion, the stainless steel coil slitting machine is an indispensable asset in metal manufacturing. Its ability to efficiently produce high-quality strips while reducing waste and labor costs makes it a preferred choice for many industries. As technology continues to advance, these machines are likely to become even more efficient, further revolutionizing the way stainless steel is processed. For manufacturers seeking to enhance their production capabilities, investing in a reliable slitting machine is a wise decision that promises long-term benefits.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025