stainless steel coil slitting machine

Stainless Steel Coil Slitting Machine An Essential Tool in Metal Processing

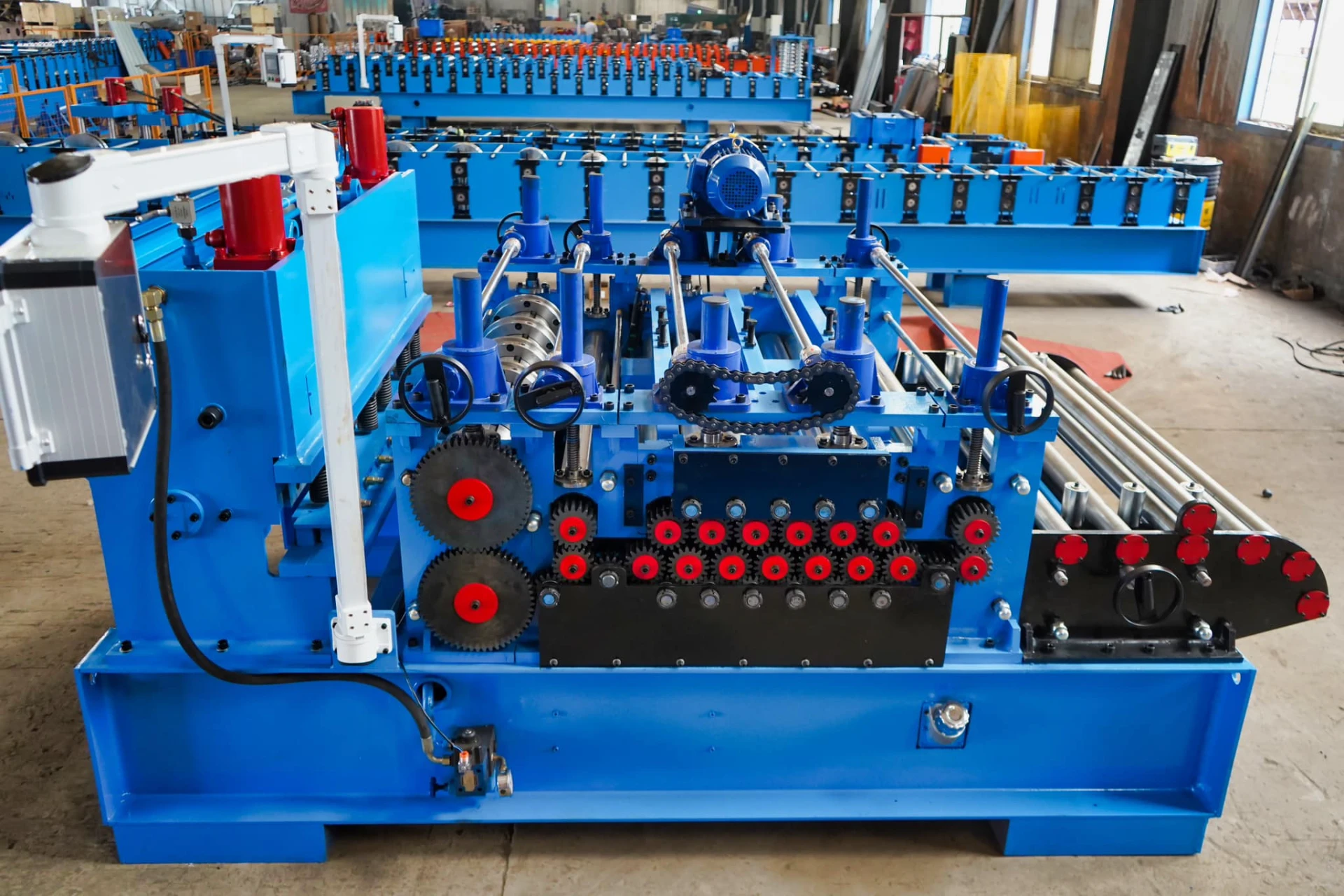

In the world of metal processing, efficiency and precision are paramount. Among the various tools available today, the stainless steel coil slitting machine stands out as a vital piece of equipment for fabricators and manufacturers. This machine transforms large rolls of stainless steel into narrower strips, allowing for greater versatility in application and enhancing the manufacturing process.

Understanding the Slitting Process

The slitting process involves feeding a wide coil of stainless steel into the machine, where it is cut into narrower strips. This is accomplished using sharp rotary knives that make quick and effective cuts along the coil’s length. The result is multiple narrower coils that can be used in various applications, ranging from automotive parts to kitchenware, and even architectural components. This flexibility is one of the key reasons metal processors invest in high-quality slitting machines.

Benefits of Stainless Steel Coil Slitting Machines

1. Precision Cutting One of the primary advantages of using a stainless steel coil slitting machine is the high level of precision it offers. The accurate cutting capabilities ensure that the final products maintain consistent dimensions, which is crucial for subsequent manufacturing processes. Precision also minimizes material waste, as manufacturers can be assured that they are only using what they need.

stainless steel coil slitting machine

2. Enhanced Efficiency In a fast-paced production environment, time is of the essence. Modern slitting machines are designed for high-speed operations, allowing for the processing of large volumes of material in a shorter timeframe. This increase in efficiency translates to higher productivity, enabling manufacturers to meet tight deadlines and respond swiftly to market demands.

3. Versatile Applications Stainless steel is renowned for its durability and resistance to corrosion, making it an ideal material for a wide array of applications. With a slitting machine, manufacturers can create customized widths of stainless steel strips tailored to their specific needs. Whether needed for construction, automotive, or consumer goods, the versatility of slitting completed by these machines ensures that numerous industries can benefit.

4. Cost-Effective Operations Investing in a stainless steel coil slitting machine can significantly reduce operational costs. By producing narrower strips in-house, companies can effectively reduce material handling costs and eliminate the need for additional processing steps. Furthermore, the efficiency gained from using these machines can lead to labor cost savings.

5. Quality Control The integration of advanced technology in modern slitting machines allows for real-time monitoring and control of the slitting process. This capability equips manufacturers with the ability to detect any deviations from the desired specifications immediately, thus maintaining high standards of quality throughout production.

Conclusion

In conclusion, the stainless steel coil slitting machine is an indispensable asset in metal processing industries. With its ability to provide precision cutting, enhance efficiency, and accommodate versatile applications, it stands as a testament to modern manufacturing technology. As industries continue to evolve and demand increasingly specialized products, the importance of reliable and efficient slitting machines will only continue to grow. For anyone involved in the fabrication or manufacturing sectors, investing in a high-quality stainless steel coil slitting machine is not just an option; it is an essential step towards remaining competitive in an ever-evolving marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025