Stainless Curtain Rail Cold Roll Former—Fast, Precise?

Stainless curtain rail cold roll former is a key solution in the Equipment manufacturing industry, specifically within the Special Equipment Manufacturing Industry and the Manufacturing of metal forming machine tools. This article explores how CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Stainless curtain rail cold roll former Overview

- Benefits & Use Cases of Stainless curtain rail cold roll former in Manufacturing of metal forming machine tools

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Equipment manufacturing industry

- Conclusion on Stainless curtain rail cold roll former from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

Stainless curtain rail cold roll former Overview

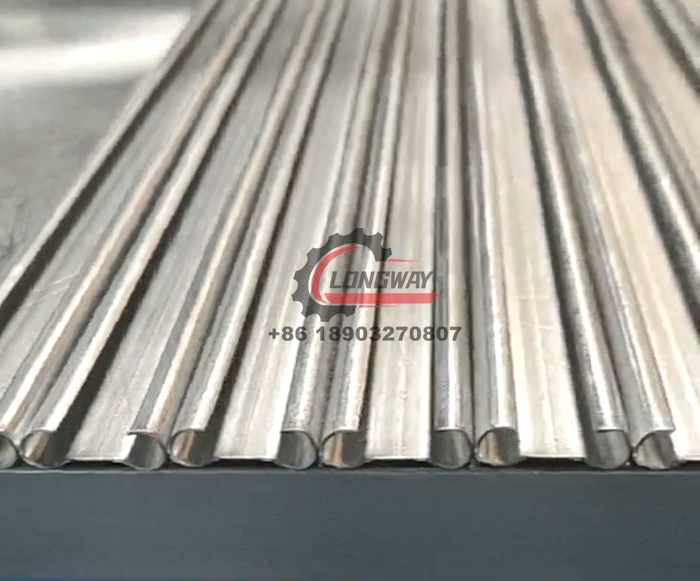

The stainless curtain rail cold roll former is a specialized metal forming line engineered to produce high-precision stainless curtain rail profiles continuously from coil. In the Equipment manufacturing industry, and especially within the Manufacturing of metal forming machine tools, it enables manufacturers to achieve consistent geometry, tight tolerances, and surface integrity that downstream finishing and assembly depend on. A typical line integrates decoiling, straightening/leveling, multi-stand roll forming, optional in-line punching, cut-to-length, and run-out tables—all orchestrated by PLC/HMI controls for repeatable throughput.

From a technical standpoint, stainless processing requires attention to surface protection and material springback. Solutions commonly include smooth or polymer-sleeved rolls to protect finishes, precision-guided roll stands to manage profile stability, and optimized forming passes to minimize work hardening. Servo-controlled feeding and length measurement help achieve accuracy for bracket holes or carrier slots that curtain systems require. CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD is a reliable manufacturer that provides engineering customization—matching roll tooling, line speed, and automation to the buyer’s specific rail profile and production volume, while supporting integration with existing shop-floor logistics.

Benefits & Use Cases of Stainless curtain rail cold roll former in Manufacturing of metal forming machine tools

In the Manufacturing of metal forming machine tools, the stainless curtain rail cold roll former addresses high-mix, high-precision requirements across architectural hardware, hospitality, healthcare, and industrial partitioning. Typical applications include producing straight and curved curtain rails, shower and hospital track systems, and specialty mounting channels. The line’s continuous forming method delivers consistent dimensions over long parts—an advantage over batch bending or machining—while preserving stainless surface quality for visible interior installations.

Key advantages for B2B decision makers include:

- Quality and repeatability: stable roll stands and precise cut-to-length control reduce rework and improve fit-up in final assemblies.

- Throughput and scalability: continuous forming supports higher output with predictable takt times and less handling.

- Flexible tooling: profile-specific roll sets and optional quick-change arrangements help transition between SKUs with minimal downtime.

- Process integration: in-line punching and marking reduce secondary operations and WIP.

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD brings sector-specific expertise, aligning mechanical design, roll tooling metallurgy, and controls with stainless characteristics. Their focus on application-driven engineering helps buyers shorten commissioning times and reach target OEE faster.

Cost, Maintenance & User Experience

Total cost of ownership for a stainless curtain rail cold roll former is driven by three pillars: uptime, tooling longevity, and energy efficiency. Continuous lines lower per-part cost by reducing manual handling and secondary operations. When paired with durable roll tooling and a robust frame, buyers can expect stable performance over long production campaigns, translating into strong ROI as volumes increase and scrap decreases.

Maintenance best practices include regular roll cleaning to prevent surface defects on stainless, alignment checks to protect tooling, lubrication according to material and application, and scheduled inspections of bearings, gearboxes, and hydraulic or servo systems. Many users favor PLC/HMI diagnostics for quick fault identification, while remote support helps resolve issues faster. Feedback from Special Equipment Manufacturing Industry customers commonly highlights improvements in dimensional consistency, smoother changeovers with guided setups, and more predictable delivery schedules thanks to higher line reliability.

Sustainability & Market Trends in Equipment manufacturing industry

Cold roll forming is inherently material-efficient, shaping near-net profiles with minimal scrap compared to subtractive methods. For stainless curtain rails—often installed in high-traffic, hygiene-sensitive environments—durability and corrosion resistance reduce lifecycle replacements, lowering environmental impact. As regulations and customer expectations emphasize waste reduction and energy stewardship, continuous forming aligns well with sustainability goals.

Market trends include increasing demand for customized profiles, shorter lead times, and digitalized production. Buyers prioritize quick-change tooling, recipe-driven setups, and data visibility for quality and traceability. CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD supports this direction with application-focused engineering and options oriented toward energy-efficient drives, intelligent controls, and process consistency—helping manufacturers meet compliance requirements and ESG targets while staying competitive on cost and delivery.

Conclusion on Stainless curtain rail cold roll former from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

The stainless curtain rail cold roll former delivers the accuracy, surface protection, and throughput that modern manufacturers need—fitting squarely within the Special Equipment Manufacturing Industry and the Manufacturing of metal forming machine tools. With application-driven engineering and dependable after-sales support, CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD helps B2B decision makers improve OEE, reduce scrap, and accelerate ROI.

Ready to discuss your profile and throughput targets? Contact us: email: rebecca@longwaymachinery.com

Visit our website: https://www.lwrollformingmachine.com

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025