Stainless Curtain Rail Cold Roll Former | High-Precision, OEM

Stainless Curtain Rail Cold Roll Former is a key solution in the Equipment manufacturing industry industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of metal forming machine tools. This article explores how CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Stainless Curtain Rail Cold Roll Former Overview

- Benefits & Use Cases of Stainless Curtain Rail Cold Roll Former in Manufacturing of metal forming machine tools

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Equipment manufacturing industry

- Conclusion on Stainless Curtain Rail Cold Roll Former from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

Stainless Curtain Rail Cold Roll Former Overview

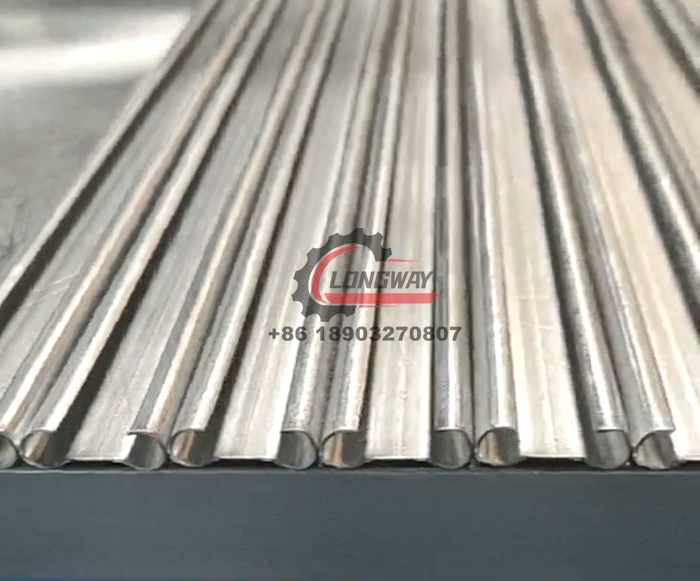

The Stainless Curtain Rail Cold Roll Former is a specialized continuous forming line engineered to produce precision stainless-steel curtain tracks and rails with consistent profiles and superior surface finish. Within the Equipment manufacturing industry—especially the Special Equipment Manufacturing Industry and the Manufacturing of metal forming machine tools segment—this machine enables OEMs and curtain hardware producers to scale output, control tolerances, and reduce scrap. Typical configurations feature a decoiler, leveling, roll forming stands, flying cut-off, run-out tables, and a PLC/HMI control suite. Options can include servo-driven feeding, quick-change cassettes, hydraulic or servo cutting, and inline punching for carriers or mounting holes. Material capabilities typically cover stainless steel strips in the 0.4–1.0 mm range, with line speeds engineered to meet throughput targets while preserving dimensional accuracy.

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD brings deep process know-how to curtain rail roll forming. Their engineering team supports profile optimization, tooling design, and commissioning, helping B2B decision makers balance CAPEX with long-term performance. With robust frames, precision-machined rollers, and brand-name electrics, the Stainless Curtain Rail Cold Roll Former is designed for stable production, repeatable quality, and simplified operator training—key factors for plants seeking to improve OEE and reduce changeover times across product variants.

Benefits & Use Cases of Stainless Curtain Rail Cold Roll Former in Manufacturing of metal forming machine tools

In manufacturing environments, this machine serves as the backbone for producing standardized and custom curtain rails for residential, hospitality, healthcare, and commercial interiors. It supports profiles for straight or curved tracks, single or double channels, and special geometries designed to improve carrier glide and load-bearing performance. Inline punching and embossing enable mounting slot creation and branding without secondary handling, streamlining takt time and reducing WIP.

Key advantages include stable forming under stainless conditions, minimized burrs for smooth carrier movement, and integrated quality control via sensors and closed-loop speed control. Quick-change tooling and recipe-based setups help producers switch between SKUs faster, while robust drives and precise roll tooling preserve profile integrity over long runs. Backed by CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD’s tooling expertise and after-sales support, the Stainless Curtain Rail Cold Roll Former becomes a scalable platform that aligns with Industry 4.0 initiatives and enterprise-level quality requirements.

Cost, Maintenance & User Experience

For B2B decision makers, total cost of ownership is driven by uptime, scrap rate, labor efficiency, and energy consumption. The Stainless Curtain Rail Cold Roll Former is engineered for durability with rigid frames, wear-resistant roll tooling, and simplified lubrication paths, helping extend service intervals. Recipe-driven controls reduce training time and setup variability, while optional quick-change cassettes and standardized spare parts minimize downtime during product transitions.

Customers in the Special Equipment Manufacturing Industry often highlight predictable quality and consistent surface finish as key benefits that reduce rework and warranty claims. With planned preventive maintenance and periodic roller reconditioning, plants can maintain line capability and protect yield. When paired with data logging and alarm histories, supervisors gain actionable insights to optimize process parameters, supporting a compelling ROI through higher OEE and faster payback horizons compared to multi-step fabrication methods.

Sustainability & Market Trends in Equipment manufacturing industry

Sustainability priorities—energy efficiency, material utilization, and recyclability—are reshaping metal forming investments. Stainless steel’s recyclability and corrosion resistance align with green building standards and lifecycle cost goals. Roll forming, by nature, supports near-net-shape production with low scrap, and modern drives with VFD/servo control help trim energy use. Inline operations (punching, cutting, marking) cut handling and transport, further improving the carbon profile of the value stream.

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD positions its Stainless Curtain Rail Cold Roll Former for evolving regulations and OEM sustainability KPIs by offering options such as closed-loop lubrication management, energy-efficient motors, and data connectivity for audit-ready reporting. As demand grows for premium interior hardware in hospitality and healthcare, producers seek flexible, low-waste forming lines—an area where LONGWAY’s application engineering and turnkey project delivery help manufacturers future-proof capacity while meeting compliance expectations.

Conclusion on Stainless Curtain Rail Cold Roll Former from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

For producers in the Equipment manufacturing industry—particularly the Special Equipment Manufacturing Industry and the Manufacturing of metal forming machine tools—the Stainless Curtain Rail Cold Roll Former delivers repeatable quality, scalable throughput, and lower lifecycle costs. With robust construction, configurable tooling, and intuitive controls, it equips factories to meet demanding lead times and quality standards. CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD’s engineering support and service culture further de-risk implementation and long-term operation. Contact us: email: rebecca@longwaymachinery.com — Visit our website: https://www.lwrollformingmachine.com

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025