Square Pipe Roll Forming Machine Manufacturer for High-Quality Steel Solutions

Square Pipe Roll Forming Machine Revolutionizing Manufacturing

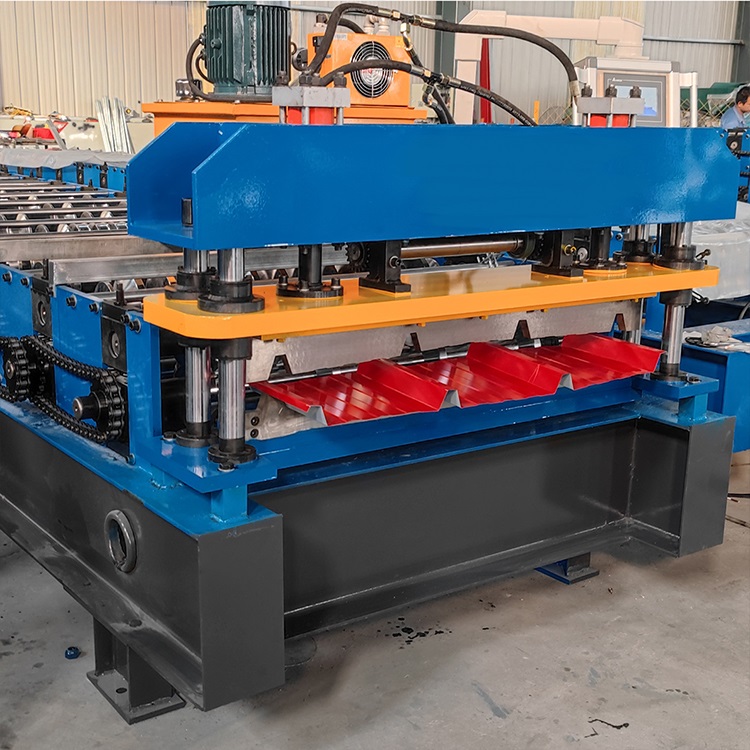

In the fast-evolving world of manufacturing, efficiency and precision are paramount. Among the various tools that facilitate these qualities, square pipe roll forming machines stand out. These advanced machines are crucial for producing square and rectangular pipes, which have become essential components across various industries, including construction, automotive, and furniture manufacturing.

A square pipe roll forming machine operates on a simple yet effective principle. It starts with a flat metal strip, usually made of steel, which is fed into a series of rollers. As the strip passes through these rollers, it undergoes a progressive shaping process. The rollers gradually form the strip into a square or rectangular profile, ensuring consistent dimensions and high-quality finishes. This method not only saves time but also minimizes waste, making it an environmentally friendly option in the manufacturing process.

One of the most significant advantages of utilizing a square pipe roll forming machine is its ability to handle varying thicknesses and sizes of metal strips. This versatility allows manufacturers to produce a wide range of square pipes tailored to specific requirements, catering to different projects and applications. Moreover, modern machines are equipped with advanced technology that ensures precision in every roll, maintaining uniformity even in large-scale production runs.

square pipe roll forming machine company

The durability of the finished products is another noteworthy benefit. Square pipes formed using these machines exhibit excellent tensile strength and structural integrity, making them ideal for load-bearing applications. This quality is particularly vital in construction, where the durability of materials directly impacts safety and longevity.

In addition to operational efficiency, investing in a square pipe roll forming machine can also enhance a company's competitiveness in the market. With the ability to produce high-quality square pipes rapidly, manufacturers can reduce lead times and respond more effectively to customer demands. This adaptability is crucial in today’s fast-paced business environment, where agility can be a significant advantage.

Moreover, ongoing innovations in this field are driving further efficiencies and functionalities. Features such as automatic adjustment systems and integrated quality control mechanisms are becoming standard, streamlining the manufacturing process and ensuring the highest quality output.

In conclusion, square pipe roll forming machines are revolutionizing the manufacturing landscape. Their efficiency, precision, and versatility make them indispensable for producing high-quality square pipes. As industries continue to evolve, these machines will undoubtedly play a crucial role in meeting the growing demands for reliable and robust metal solutions. Investing in such technology is not merely an option; it is a strategic move towards enhancing productivity and competitiveness in the manufacturing arena.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025