Efficient Square Downspout Production Machines for Durable Gutter Solutions

The Square Downspout Machine Revolutionizing Gutter Systems

In the world of construction and home improvement, innovation is a continuous process. One significant advancement that has gained traction in recent years is the square downspout machine. This specialized equipment is designed to manufacture square downspouts efficiently, catering to the growing demand for effective drainage systems. This article will delve into the importance of square downspouts, the workings of square downspout machines, and the benefits they offer to contractors and homeowners alike.

Understanding Downspouts

Before we explore the machinery, it’s essential to understand what downspouts are and their role in a building's drainage system. Downspouts are vertical pipes that guide rainwater from gutters down to the ground or drainage systems. Traditionally, round downspouts have been the go-to option for many construction projects. However, square downspouts have emerged as a popular alternative for several reasons.

Compared to their round counterparts, square downspouts offer a modern aesthetic that many homeowners and architects prefer. Additionally, they can be easier to install and maintain, especially in systems that require multiple downspouts to handle larger volumes of water. Their flat surfaces also make them suitable for various finishing styles, as they can be seamlessly integrated into the overall design of a building.

The Functionality of Square Downspout Machines

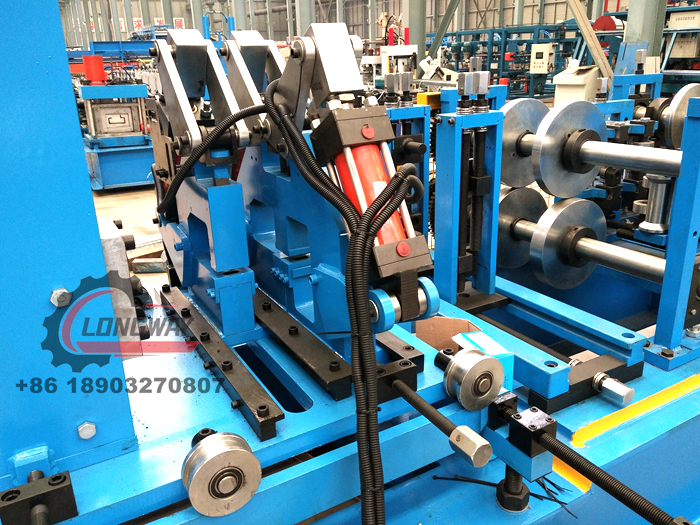

A square downspout machine is an advanced piece of equipment that creates these square downspouts from metal coils, typically aluminum or galvanized steel. The process begins with feeding a roll of metal into the machine, which then uses a series of rollers and dies to shape the material into the desired square profile. The machine can produce downspouts in various sizes and lengths, making it a versatile tool for contractors.

One of the most significant advantages of using a square downspout machine is the speed and efficiency it offers. Traditional methods of cutting and shaping downspouts can be labor-intensive and time-consuming. In contrast, modern machines can create precise downspouts in a matter of minutes, significantly reducing labor costs and project timelines.

square downspout machine

Furthermore, many of these machines are equipped with programmable settings, allowing users to customize the dimensions and specifications of the downspouts according to project requirements. This feature fosters greater flexibility and precision, ensuring that downspouts meet the unique needs of each building.

Benefits to Contractors and Homeowners

The introduction of square downspout machines has several benefits that are especially valuable to contractors and homeowners. Firstly, the ability to quickly produce custom square downspouts means that projects can be completed more efficiently. Contractors can maintain tighter schedules and potentially take on more projects due to the reduced production time.

Secondly, the quality of the finished product is significantly improved. Square downspout machines provide uniformity in shape and size, minimizing the variability often seen in manually crafted downspouts. This consistency contributes to a more polished and professional appearance, which is crucial for both new constructions and renovations.

For homeowners, the tailored options provided by these machines allow for greater personalization in their gutter systems. They can select from a range of colors, finishes, and sizes that fit their home’s architecture, enhancing curb appeal while ensuring efficient water management.

Conclusion

In conclusion, the square downspout machine represents a significant evolution in the production of drainage systems in the construction industry. Its ability to efficiently produce aesthetically pleasing and functional square downspouts caters to the modern demands of both contractors and homeowners. As the industry continues to embrace technological advancements, it is evident that tools like the square downspout machine will play a pivotal role in shaping our buildings and improving their functionality. With the right equipment, achieving a perfect blend of style and efficiency in downspout design has never been easier.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025