Innovative Solutions for Square Downspout Production Machinery and Efficiency Enhancement

Understanding the Square Downspout Machine A Key Tool for Efficient Water Management

In the world of construction and water management, the significance of effective drainage systems cannot be overstated. Among the various components of these systems is the downspout, a pipe that directs rainwater from the roof to the ground or drainage system. As the demand for structured and aesthetically pleasing building designs increases, so does the need for machinery that can create downspouts that meet specific requirements. This is where the square downspout machine comes into play.

What is a Square Downspout Machine?

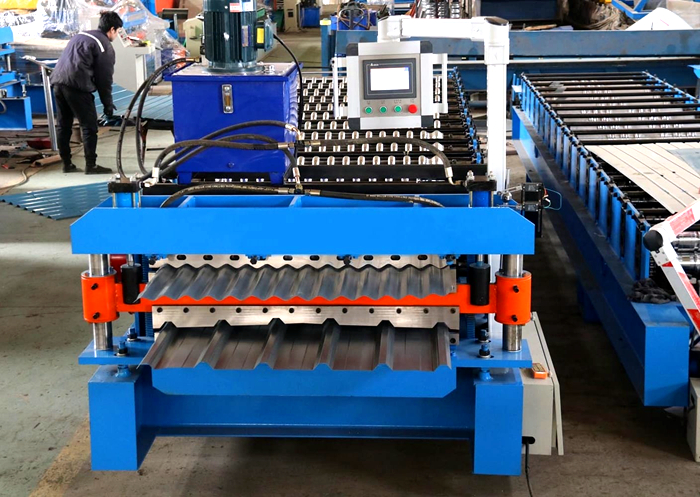

A square downspout machine is a specialized piece of equipment designed to produce square-shaped downspouts. Unlike traditional round downspouts, square downspouts offer a modern, sleek appearance that aligns well with contemporary architectural designs. This machine typically works by feeding metal sheets, such as aluminum or galvanized steel, into the machinery, which then roll-forms them into square profiles. The process is not only efficient but also allows for customization in terms of color and material, catering to the diverse needs of builders and designers.

The Importance of Square Downspouts

Square downspouts have gained popularity for several reasons. Firstly, their design is often more compatible with modern architectural styles. They can easily be integrated into buildings that have sharp lines and geometric shapes, providing a streamlined look that complements the overall aesthetic. Moreover, square downspouts can be more efficient in handling larger volumes of water, which is vital in preventing water damage during heavy rainfall.

Secondly, square downspouts can be easier to fabricate and install than their round counterparts, especially when it comes to custom sizes and designs. The square profile allows for better alignment with existing structural elements, reducing the complexity that some installations may present.

Features of a Square Downspout Machine

When it comes to selecting or understanding a square downspout machine, several features are crucial

1. Versatility Many machines are designed to accommodate different materials, enabling operators to switch between aluminum, copper, or galvanized steel depending on project requirements.

square downspout machine

2. Customization Options The best machines allow for on-the-fly adjustments, enabling users to create custom lengths and profiles as needed without extensive downtime.

3. Efficiency High-quality machines streamline the production process, significantly reducing the time it takes to produce downspouts compared to manual methods.

4. Safety Features Modern machines come equipped with various safety mechanisms to protect operators, such as automatic shut-off systems, ensuring a secure working environment.

5. Easy Maintenance As with any machinery, ease of maintenance is essential for ensuring longevity and performance. A good square downspout machine should be designed for easy access to critical components.

Applications in the Construction Industry

Square downspout machines play a crucial role in various sectors of the construction industry. They are particularly valuable in commercial construction, where large buildings with complex roofing structures require efficient and effective rainwater management systems. Additionally, residential builders increasingly turn to these machines to meet client demands for customized and stylish water drainage solutions.

Moreover, as sustainability becomes a more pressing concern in construction, there is a rising interest in downspouts that minimize water runoff and promote effective water management. Square downspout machines can be integral to these efforts, enabling builders to create systems that cater to eco-friendly practices.

Conclusion

In summary, the square downspout machine is an essential tool in modern construction and water management strategies. With their ability to produce aesthetically pleasing, efficient, and customizable downspouts, these machines help builders and designers address both functional and aesthetic requirements. As the architecture of our built environments continues to evolve, the demand for innovative solutions like the square downspout machine will only grow, underscoring its significance in sustainable construction practices and effective water management systems.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025