Square Downpipe Fabrication Machine for Efficient Roll Forming Solutions

The Square Downpipe Roll Forming Machine Revolutionizing the Production of Downpipes

In the construction and plumbing industry, efficiency and precision are paramount. As demands for innovative and eco-friendly building solutions increase, the need for high-quality downpipes has never been more pressing. The square downpipe roll forming machine is at the forefront of this evolution, providing a cutting-edge solution for manufacturers seeking to produce square downpipes with speed, accuracy, and minimal waste.

Understanding the Roll Forming Process

Roll forming is a continuous bending operation in which a long strip of metal is passed through a series of roll sets until the desired cross-section is achieved. The process allows for the production of complex shapes while maintaining high dimensional accuracy. The square downpipe roll forming machine is specifically designed to create square downpipes, which are widely used in rainwater drainage systems, enhancing both functionality and aesthetic appeal in building designs.

Key Features of Square Downpipe Roll Forming Machines

1. Advanced Technology Modern square downpipe roll forming machines are equipped with advanced technology that ensures precision in every step of the manufacturing process. Features such as automatic thickness adjustment, PLC control systems, and real-time monitoring contribute to a streamlined workflow.

2. Versatility These machines are not limited to producing only one size of downpipe. Many models come with adjustable settings that allow manufacturers to change dimensions quickly, accommodating varying project requirements without significant downtime.

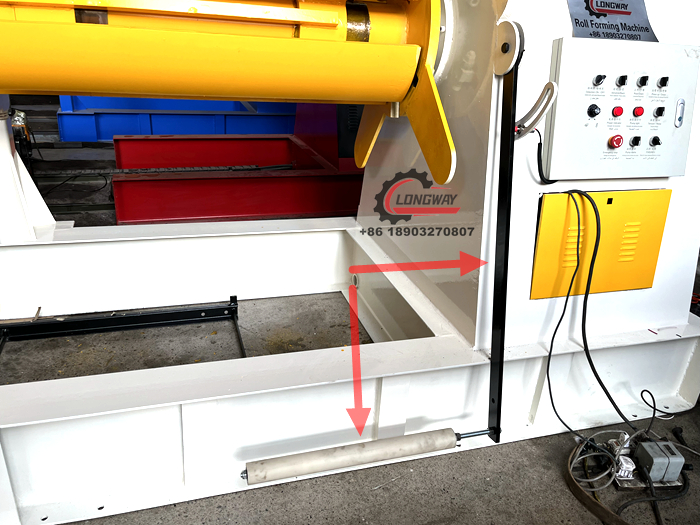

square downpipe roll forming machine

3. Durability Built with high-quality materials, square downpipe roll forming machines are designed to withstand the rigors of heavy industrial use. Their robust construction ensures longevity, reducing the costs associated with maintenance and replacement.

4. Efficiency Speed is a critical factor in any manufacturing process. Square downpipe roll forming machines are capable of producing large volumes of downpipes in a short time, helping manufacturers meet tight deadlines while reducing labor costs.

5. Eco-Friendly Production The capability of these machines to reduce material waste makes them an environmentally friendly choice. The precise cutting and forming processes minimize scrap material, aligning with global sustainability goals.

Applications in Various Industries

Square downpipes are essential components in various sectors, including residential, commercial, and industrial construction. Their design not only facilitates effective rainwater drainage but also contributes to the aesthetic aspects of a building. Moreover, with the increase in urbanization, the demand for efficient drainage systems has surged, making the square downpipe roll forming machine a vital asset for manufacturers looking to capitalize on this growing market.

Conclusion

In the fast-paced world of construction and manufacturing, the square downpipe roll forming machine stands out as a game-changing investment. By merging advanced technology with efficient production methods, it offers significant advantages that cater to the needs of modern builders and manufacturers. As sustainability becomes increasingly important, the eco-friendly nature of this machine ensures that businesses can grow while also taking care of the planet. For any manufacturer committed to quality and efficiency, integrating a square downpipe roll forming machine into their production line could very well be the key to staying competitive in a rapidly evolving industry.

-

Top Metal Roofing Machine ManufacturersNewsAug.04, 2025

-

Production Line with a Gutter Forming Machine for SaleNewsAug.04, 2025

-

Production Capacity with a Purlin Machine for SaleNewsAug.04, 2025

-

Exploring Roofing Sheets Manufacturing Machine PriceNewsAug.04, 2025

-

Drywall Roll Forming Machine for SaleNewsAug.04, 2025

-

Best Roof Panel Machine for SaleNewsAug.04, 2025

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025