Soffit Roll Forming Equipment Manufacturers and Their Innovative Solutions for Construction Needs

Understanding Soffit Roll Forming Machine Factories

Roll forming is a continuous bending operation in which a long strip of metal, usually coiled steel, is fed through consecutive pairs of rolls. In this process, the metal is gradually shaped into an elongated profile. One of the specialized applications of this technique is in the manufacturing of soffit panels, which are an essential element in building construction, particularly in residential and commercial buildings.

What is a Soffit?

A soffit is the underside of any construction element, including archways, eaves, or overhangs. It serves both functional and aesthetic purposes. Functionally, soffits help ventilate attics and provide insulation, while aesthetically, they give buildings a more finished look. Soffits protect the rafters from weather damage and contribute to the overall architectural design.

The Role of Soffit Roll Forming Machines

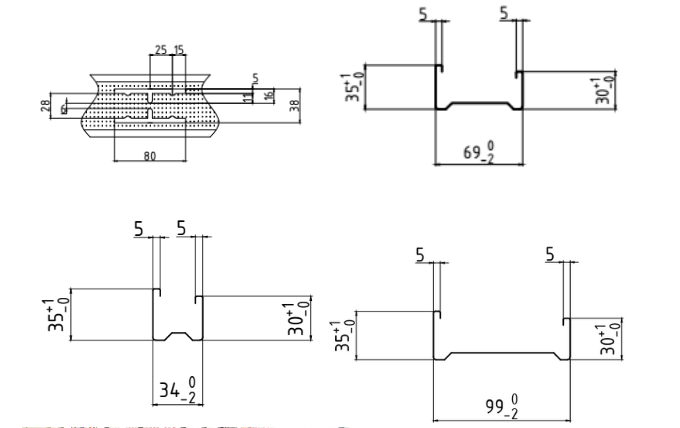

Soffit roll forming machines are specialized equipment designed to manufacture soffit panels in specific profiles. These machines operate by passing flat sheet metal through a series of rollers that gradually shape the sheet into a desired cross-section. The technology allows for mass production of uniform and consistent soffit panels, which are crucial in construction projects.

Features of Soffit Roll Forming Machines

1. Customizable Designs Many soffit roll forming machines can be tailored to produce various profiles based on customer requirements. This flexibility allows manufacturers to meet specific design criteria, accommodating different architectural styles. 2. High Efficiency The continuous operation of roll forming machines contributes to higher production rates compared to traditional manufacturing methods. This efficiency reduces lead times and meets the demands of fast-paced construction schedules.

3. Material Versatility Soffit roll forming machines can work with various metal materials, including aluminum, galvanized steel, and stainless steel. This versatility allows builders to choose materials that best fit their project's needs.

4. Cost-Effectiveness By streamlining the production process, manufacturers can lower labor costs and minimize waste. The ability to produce materials in large volumes makes roll forming a cost-effective option for many construction companies.

soffit roll forming machine factories

5. Durability and Quality The roll forming process leads to strong and durable panels that can withstand environmental stresses. The manufacturing process ensures high-quality products with minimal defects.

Importance of Factories in the Manufacturing Process

Soffit roll forming machine factories are essential for the large-scale production of soffit panels. These factories typically involve several stages of design, production, quality control, and packaging

1. Design and Prototyping Many factories start with a design phase where engineers create CAD models for different soffit profiles. Prototypes may be made for testing purposes, ensuring that the finished product meets all specifications and standards.

2. Production Line Once designs are finalized, production lines are set up with multiple roll forming machines tailored for specific profiles. This setup ensures high efficiency and swift production capabilities.

3. Quality Control Quality assurance teams are integral to the factory process. They meticulously inspect the finished products, ensuring they meet all required safety and performance standards. This inspection process includes checking dimensional accuracy, surface finish, and mechanical properties.

4. Packaging and Distribution After passing quality control, the soffit panels are packaged for shipment. Efficient packaging not only protects the products during transit but also saves space for storage.

Conclusion

Soffit roll forming machine factories play a vital role in the construction industry by providing high-quality, cost-effective, and versatile soffit panels. As building standards evolve and the demand for architectural variety increases, these factories are positioned to meet the needs of modern construction. The adoption of advanced technology in roll forming processes ensures that manufacturers can produce innovative solutions tailored to specific projects, contributing to the lasting beauty and functionality of buildings around the world. As we move into an era of sustainability, the role of these factories will likely expand, incorporating eco-friendly materials and processes to create even more efficient products for the industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025