soffit roll forming machine company

The Importance of Soffit Roll Forming Machines in Modern Construction

In today's fast-paced construction industry, efficiency, durability, and aesthetic appeal are paramount. One key player in achieving these goals is the soffit roll forming machine. Designed to create soffit panels—integral components of building architecture—these machines blend cutting-edge technology with innovative design. This article delves into the significance of soffit roll forming machine companies and their impact on modern construction practices.

Understanding Soffit and Its Role in Construction

The term soffit refers to the underside of any construction element, such as eaves, ceilings, and archways. It serves both functional and ornamental purposes, providing ventilation, concealing structural elements, and enhancing the overall aesthetic of a building. The choice of materials used for soffits can significantly influence a structure's durability and maintenance requirements. Traditionally, soffits were crafted using wood or aluminum, but advancements in technology have given rise to more efficient manufacturing processes.

The Evolution of Soffit Roll Forming Machines

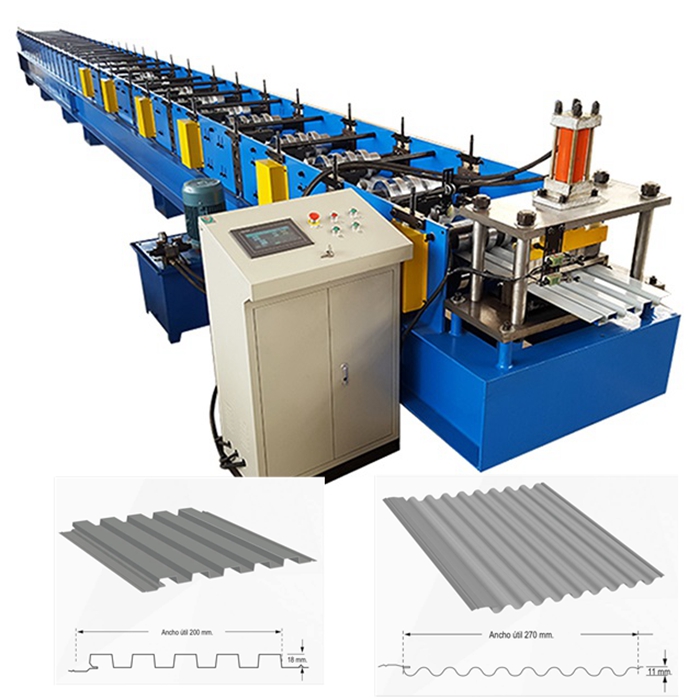

Soffit roll forming machines represent a significant innovation in the production of soffit panels. These machines utilize continuous metal sheets, which can be transformed into specific shapes and profiles through a series of rollers. The result is a consistent, high-quality product that can be customized to meet various architectural styles and structural requirements.

Initially designed for industrial use, soffit roll forming machines have evolved to include advanced features like automated controls, digital interfaces, and enhanced safety mechanisms. This evolution reflects a broader trend within the construction industry towards increased automation and efficiency, driven by the need to reduce labor costs while improving product quality.

Benefits of Using Soffit Roll Forming Machines

1. Precision Engineering One of the standout features of soffit roll forming machines is their ability to produce panels with exact specifications. This precision ensures that the panels fit seamlessly into the intended spaces, reducing waste and minimizing installation time.

soffit roll forming machine company

2. Material Versatility These machines can work with a variety of materials, including aluminum, steel, and PVC. This versatility allows construction companies to select materials that align with their project goals, whether they prioritize cost, durability, or aesthetic appeal.

3. Efficiency and Speed In a world where time is money, the speed of production that soffit roll forming machines offer cannot be overlooked. They can produce large quantities of panels in a relatively short time frame, enabling projects to stay on schedule and within budget.

4. Cost-Effectiveness While the initial investment in a soffit roll forming machine can be significant, the long-term savings are substantial. By producing panels in-house, companies can save on material costs and reduce labor expenses, ultimately lowering the overall project cost.

5. Customization Options Many soffit roll forming machine companies offer customization options, allowing clients to create unique profiles and designs that distinguish their projects. This flexibility fosters creativity and enhances the aesthetic value of buildings.

The Role of Soffit Roll Forming Machine Companies

The emergence of specialized soffit roll forming machine companies has played a crucial role in revolutionizing the construction industry. These companies not only manufacture the machines but also provide support services, including training, maintenance, and spare parts supply. Their expertise ensures that construction firms can maximize the potential of the machines, improving overall productivity.

Moreover, as sustainability becomes an increasing priority in construction, soffit roll forming machine manufacturers are adopting eco-friendly practices. Many are implementing energy-efficient technologies and sourcing sustainable materials, demonstrating a commitment to reducing the industry's environmental impact.

Conclusion

In summary, soffit roll forming machines are essential tools that contribute to the efficiency, cost-effectiveness, and quality of modern construction projects. As the industry continues to evolve, the importance of these machines—and the companies that produce them—will only grow. By embracing the advancements in soffit roll forming technology, construction professionals can ensure their projects not only meet but exceed contemporary standards of design and functionality, ultimately leading to better buildings and more satisfied clients.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025