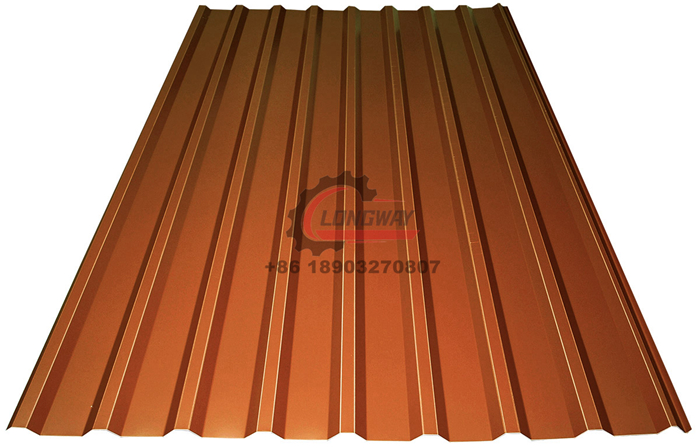

soffit roll former

Understanding Soffit Roll Formers A Key Element in Modern Construction

In the realm of modern construction, efficiency and precision are paramount. One technology that has significantly contributed to these aspects is the soffit roll former. This specialized machinery is designed to create soffit panels, which are essential elements in various architectural projects, particularly in residential and commercial buildings.

A soffit is the underside of a roof overhang, eave, or arch that provides both aesthetic appeal and functional benefits. Soffit panels serve multiple purposes, including ventilation for the attic space, protection from weather elements, and integration of insulation. The role of soffit roll formers in manufacturing these panels cannot be understated, as they allow for the continuous production of custom profiles with minimal waste.

How Soffit Roll Formers Work

Soffit roll formers utilize a process known as roll forming. This involves feeding a continuous sheet of metal, usually aluminum or galvanized steel, through a series of rollers that gradually shape it into the desired profile. The precision of this process ensures that each panel maintains consistent dimensions, which is crucial for both installation and visual appeal.

One of the key advantages of using a soffit roll former is the ability to customize the design. Builders can specify the exact profile, thickness, and finish of the material, ensuring that the final product aligns with the architectural vision of the project. This customization extends to color options as well, allowing for seamless integration with the overall aesthetics of the building.

soffit roll former

Efficiency and Cost-Effectiveness

Another significant benefit of soffit roll formers is their efficiency. These machines can produce a high volume of soffit panels in a short period, reducing labor costs and minimizing production downtime. Additionally, the roll forming process results in minimal scrap, making it a cost-effective solution for manufacturers. The reduced waste not only helps in controlling costs but also supports environmentally sustainable practices in the construction industry.

Advanced Features in Modern Roll Formers

Modern soffit roll formers come equipped with advanced features such as automated controls, digital displays, and integration capabilities with other manufacturing systems. These enhancements facilitate easy adjustments and quick setups for different soffit profiles, further streamlining the production process. Furthermore, some machines include features like coil cradle systems, which improve material handling and ensure smooth operation.

Conclusion

In conclusion, soffit roll formers play an integral role in contemporary construction, offering a perfect blend of efficiency, customization, and cost-effectiveness. As building designs evolve and the demand for high-quality materials increases, the importance of these machines will continue to grow. For contractors, builders, and manufacturers, investing in advanced soffit roll formers is not just a choice; it is a strategic decision that can significantly enhance the quality and aesthetics of modern construction projects. Their ability to produce precision-engineered soffit panels is invaluable, ensuring that structures not only meet but exceed expectations in performance and design.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025