Soffit Roll Forming Machines for Efficient Building and Construction Solutions

The Importance of Soffit Roll Formers in Modern Construction

In contemporary construction, efficiency, quality, and sustainability are paramount. Among the various tools and techniques employed in the industry, the soffit roll former stands out as an essential machine for fabricating architectural components that enhance both the functionality and aesthetic appeal of buildings. This article delves into the role of soffit roll formers, their benefits, and their applications in modern construction.

What is a Soffit Roll Former?

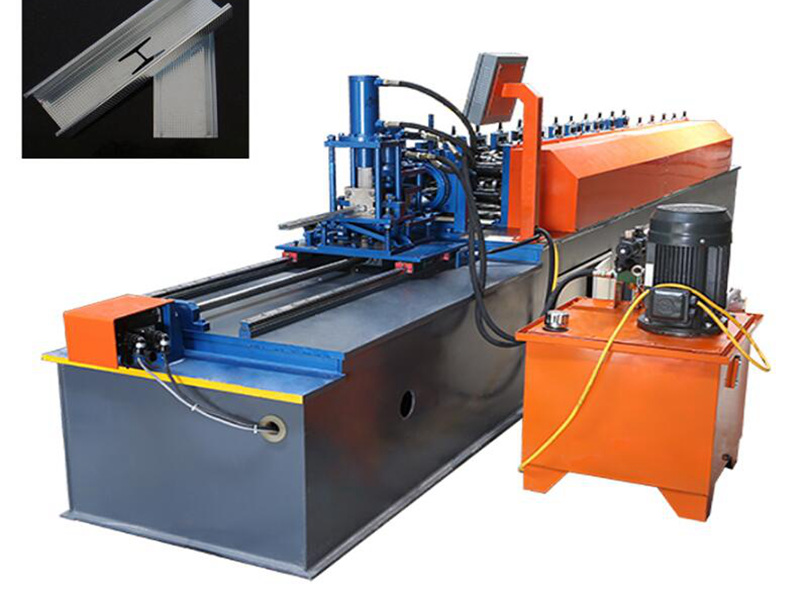

A soffit roll former is a specialized machine designed to produce soffit panels and various other metal components. Soffits are the sections beneath the eaves of a roof, providing essential ventilation and a finished look to the underside of overhangs. These panels can be made from different materials, including aluminum, steel, and vinyl. The roll former transforms flat metal coils into specified shapes through a series of rollers and dies, ensuring precision and consistency.

Benefits of Using Soffit Roll Formers

1. Precision and Customization One of the standout features of soffit roll formers is their ability to produce custom profiles. Builders can tailor dimensions, thickness, and finishes to meet specific architectural requirements. This level of customization ensures that each project maintains its unique character.

2. Efficiency in Production The automation and streamlined processes offered by soffit roll formers lead to increased production efficiency. These machines can produce large quantities of soffit panels in a shorter timeframe than traditional methods, allowing contractors to meet tight project timelines.

3. Cost-Effectiveness While the initial investment in a soffit roll former may be significant, the long-term savings can be considerable. Reduced labor costs, minimized waste, and the ability to produce materials on-site can lead to lower overall project costs. This is particularly advantageous for contractors looking to maximize their profit margins.

4. Durability and Maintenance Metal soffits created using roll forming technology are typically more durable than traditional materials. They resist warping, cracking, and fading, ensuring that the aesthetic quality of the building is maintained over time. Furthermore, metal soffits are easier to clean and maintain, contributing to the overall longevity of the structure.

soffit roll former

5. Sustainable Building Practices With a growing emphasis on sustainability in construction, soffit roll formers support green building practices. Metal can be recycled at the end of its life cycle, reducing waste in landfills. Additionally, the energy efficiency of buildings with well-ventilated soffits can lower heating and cooling costs, contributing to a smaller carbon footprint.

Applications of Soffit Roll Formers

Soffit roll formers are used in various construction applications, including

- Residential Buildings Homeowners and builders often utilize soffit roll formers to create attractive soffit panels that enhance curb appeal while providing necessary ventilation for attics.

- Commercial Structures In commercial construction, soffit panels are integral in creating a polished look for storefronts, shopping centers, and office buildings, contributing to a professional atmosphere.

- Industrial Projects Manufacturing facilities benefit from having durable metal soffits that withstand the demands of industrial environments. The resilience of metal makes it an ideal choice for such applications.

- Renovation Projects For renovations, soffit roll formers allow for easy adaptation and integration of modern features into older structures, updating their appearance while maintaining structural integrity.

Conclusion

Soffit roll formers represent an important advancement in building technology, providing architects and builders with tools to create aesthetically pleasing and functional designs. The benefits of precision, efficiency, cost-effectiveness, durability, and sustainability underscore their value in the construction industry. As the sector continues to evolve, the role of soffit roll formers is likely to become even more integral to the successful completion of modern construction projects. By embracing this innovative technology, builders can ensure they meet the challenges of contemporary architecture while adhering to the principles of efficiency and sustainability.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025