soffit panel machine factory

The Importance of Soffit Panel Machine Factories in Modern Construction

In the modern construction landscape, the demand for high-quality building materials is ever-increasing. Among these materials, soffit panels play a crucial role in enhancing both the aesthetic appeal and functional integrity of structures. As a result, the manufacturing of soffit panels has evolved into a sophisticated industry, leading to the establishment of specialized soffit panel machine factories.

Soffit panels are typically installed under the eaves of roofs to provide a finished look while allowing for ventilation and preventing moisture accumulation. They serve a dual purpose improving energy efficiency by regulating airflow and adding architectural beauty to residential and commercial buildings. With increasing awareness of sustainability and energy efficiency, the demand for these panels has surged, necessitating advanced manufacturing solutions.

The Importance of Soffit Panel Machine Factories in Modern Construction

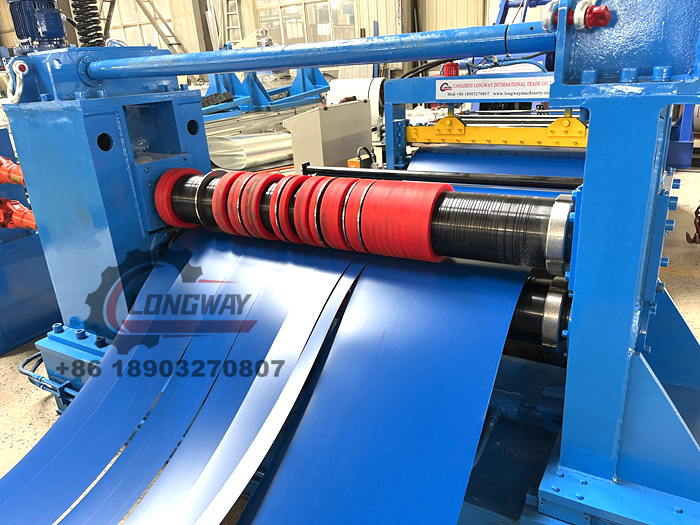

One of the key advantages of using dedicated soffit panel machines is efficiency. Automated systems streamline the production process, reducing labor costs while increasing output. High-speed cutting and molding machines can produce numerous panels in a fraction of the time it would take manual processes, significantly enhancing factory productivity. Additionally, advanced software integrated into these machines facilitates real-time monitoring and quality control, ensuring that each panel meets rigorous industry standards.

soffit panel machine factory

Moreover, the use of advanced materials technology in soffit panel production plays a vital role in enhancing the durability and longevity of the panels. For instance, modern factories often utilize materials with UV resistance and weatherproofing properties, ensuring that the soffit panels can withstand harsh environmental conditions. This longevity not only benefits homeowners by reducing the need for repairs and replacements but also contributes to sustainable construction practices.

The environmental impact of soffit panel manufacturing is also a growing concern. Many factories are adopting eco-friendly practices, such as using recycled materials and implementing waste reduction strategies. These initiatives not only align with global sustainability goals but also meet the increasing consumer demand for environmentally friendly building products. As a result, soffit panel machine factories are becoming leaders in the drive towards greener manufacturing practices.

In addition to producing high-quality panels, soffit panel machine factories must also prioritize training and development for their workforce. Skilled operators are essential for maintaining the efficiency and safety of factory operations. Investing in employee training not only enhances the overall quality of the products but also fosters a culture of innovation and continuous improvement within the factory.

In conclusion, soffit panel machine factories have become indispensable in the construction industry. Their ability to produce high-quality, customizable, and sustainable soffit panels plays a vital role in meeting the modern demands of construction. As the industry continues to evolve, these factories will undoubtedly remain at the forefront, driving innovation and quality in building materials manufacturing. With an increasing emphasis on efficiency, sustainability, and design, the future of soffit panel production looks promising, paving the way for better, more beautiful, and more energy-efficient buildings.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025