Soffit Panel Manufacturing Equipment and Production Line Solutions

The Rise of Soffit Panel Machine Factories Transforming the Construction Industry

In recent years, the construction and building materials industry has witnessed significant advancements in technology, paving the way for innovative manufacturing solutions. Among these developments, soffit panel machine factories have emerged as key players, revolutionizing the production of soffit panels. Soffit panels are essential components in modern architecture, serving both functional and aesthetic purposes when installed on the underside of roof overhangs and eaves. This article explores the significance of soffit panel machine factories, their manufacturing processes, and their impact on the construction sector.

Understanding Soffit Panels

Soffit panels serve as a protective covering for the spaces between the roofline and the exterior wall of a building. These panels play a critical role in ventilation, allowing air circulation in attics and preventing moisture buildup, which can lead to structural damage. Additionally, they enhance the visual appeal of a structure, contributing to overall architectural beauty. Traditionally made from wood, soffit panels are now manufactured from various materials such as vinyl, aluminum, and fiber cement, each offering unique benefits and characteristics.

The Role of Soffit Panel Machine Factories

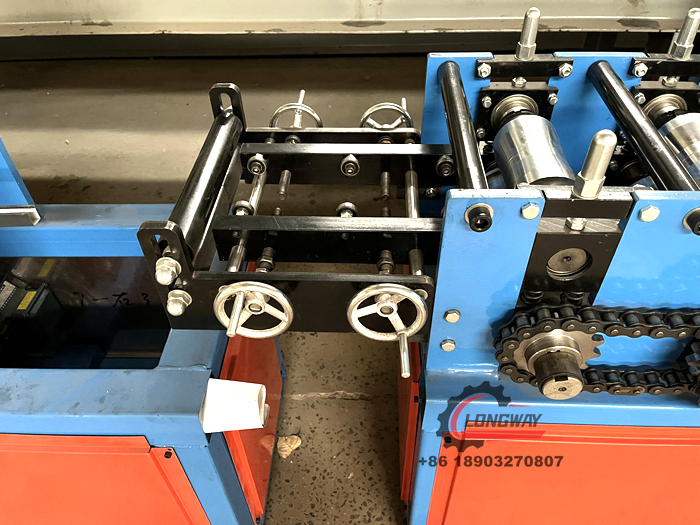

Soffit panel machine factories specialize in the production of machinery designed to manufacture these panels efficiently and accurately. The rise of automated manufacturing has transformed how soffit panels are produced, significantly increasing output while reducing labor costs. Advanced machines can handle the entire manufacturing process, from cutting and shaping raw materials to finishing and packaging. This automation leads to higher consistency in the quality of the panels produced and shortens lead times, making it easier for construction companies to obtain the materials they need promptly.

Modern soffit panel machines typically incorporate cutting-edge technology, including computer numerically controlled (CNC) systems, which enable precise cutting and detailing of panels. As the demand for customized and varied designs grows, these machines can be programmed to produce a wide range of styles and finishes, catering to diverse architectural preferences. This flexibility is crucial in a contemporary construction market that increasingly values personalization and uniqueness.

Environmental Considerations

soffit panel machine factories

With the global push toward more sustainable building practices, soffit panel machine factories are also responding by focusing on eco-friendly production methods. Manufacturers are incorporating recycled materials into their products, producing panels that are both durable and environmentally responsible. Additionally, many factories are implementing energy-efficient technologies to minimize their carbon footprint during production.

Using materials like vinyl, which can be manufactured from recycled substances and is also recyclable itself, aligns with the construction industry's growing emphasis on sustainability. Soffit panel machine factories that prioritize green manufacturing practices not only mitigate environmental impacts but also cater to the increasing number of clients who seek sustainable building solutions.

Economic Impact

The establishment of soffit panel machine factories also has significant implications for the economy. By streamlining production processes and enhancing efficiency, these factories contribute to job creation and local economic growth. The automation of manufacturing can lead to the need for skilled technicians who can oversee operations, thereby providing new employment opportunities in the region.

Moreover, by ensuring a steady supply of high-quality soffit panels, these factories support the construction industry's stability, allowing contractors to deliver projects on time without compromising on material quality. This reliability fosters greater trust and collaboration between builders, suppliers, and manufacturers.

Conclusion

Soffit panel machine factories are not merely manufacturing hubs; they represent a pivotal facet of the modern construction landscape. As they continue to evolve, these factories lead the charge in innovation, sustainability, and economic growth. With the construction industry constantly seeking efficiency and environmentally responsible practices, soffit panel machine factories will play an increasingly important role in shaping the future of building materials and architectural design. As we look forward, it is clear that the integration of advanced technology and a commitment to sustainable practices will define the next generation of manufacturing in this sector.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025