snap lock panel machine

The Snap Lock Panel Machine Revolutionizing Panel Production

In the modern manufacturing landscape, efficiency and innovation are paramount, especially within the construction and industrial sectors. One remarkable advancement that has gained significant traction in recent years is the snap lock panel machine. This machinery is designed to streamline the production of snap lock panels, which are crucial components in various applications, including roofing, wall systems, and modular buildings.

What is a Snap Lock Panel?

Before delving into the intricacies of the snap lock panel machine, it is essential to understand what snap lock panels are. These panels are designed to interlock seamlessly, creating a sturdy and weather-resistant structure. The snap lock mechanism allows for easy assembly and disassembly, making them ideal for both permanent and temporary installations. This versatility has made them a preferred choice for builders and contractors seeking efficiency and durability.

The Role of Snap Lock Panel Machines

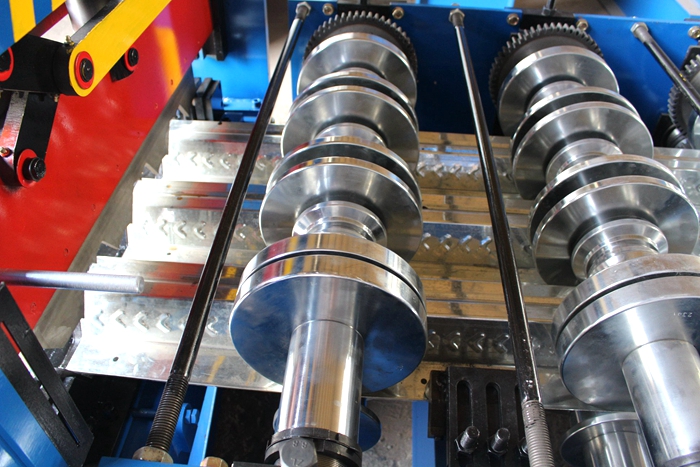

The snap lock panel machine is a specialized piece of equipment that automates the production of these panels. With the use of advanced technology, these machines significantly enhance the speed and precision of panel manufacturing. The operator inputs specific dimensions and designs, and the machine does the rest, cutting, shaping, and locking the panels into place.

One of the most significant benefits of using a snap lock panel machine is the reduction in labor costs. Traditional methods of panel production often require numerous workers and meticulous manual labor. However, a machine can accomplish the same tasks in a fraction of the time, allowing companies to allocate resources more efficiently. Furthermore, the automation of this process results in fewer errors, ensuring that each panel meets the required specifications.

snap lock panel machine

Key Features of Snap Lock Panel Machines

Snap lock panel machines come equipped with various features that enhance their functionality and ease of use. High-quality machines are built with durable materials that can withstand rigorous production demands. They often include advanced control systems that allow operators to monitor and adjust settings with precision. Additionally, many machines are designed with safety features to protect operators while maintaining efficiency in production.

One of the more advanced models incorporates automated feeding systems, which streamline the input of raw materials into the machine. This not only speeds up the production process but also minimizes waste by ensuring precise cuts and shapes. Some machines also offer the capability to produce custom panel designs, allowing manufacturers to cater to diverse client needs.

Environmental Considerations

As the construction industry moves towards more sustainable practices, the snap lock panel machine contributes by enabling the production of eco-friendly materials. The efficient use of raw materials minimizes waste, and the durability of snap lock panels means fewer replacements will be necessary over time. Moreover, many manufacturers are now utilizing recycled materials in their panels, showcasing a commitment to environmental responsibility.

Conclusion

The snap lock panel machine represents a significant evolution in the production of interlocking panels, providing crucial advantages in terms of efficiency, cost savings, and sustainability. As the demand for modular construction and innovative building solutions continues to rise, these machines are poised to play an increasingly vital role in shaping the future of the industry. By embracing technology and automation, manufacturers can meet market demands while maintaining high standards of quality and environmental consciousness.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025