slitting line

Understanding the Slitting Line Process in Metal Processing

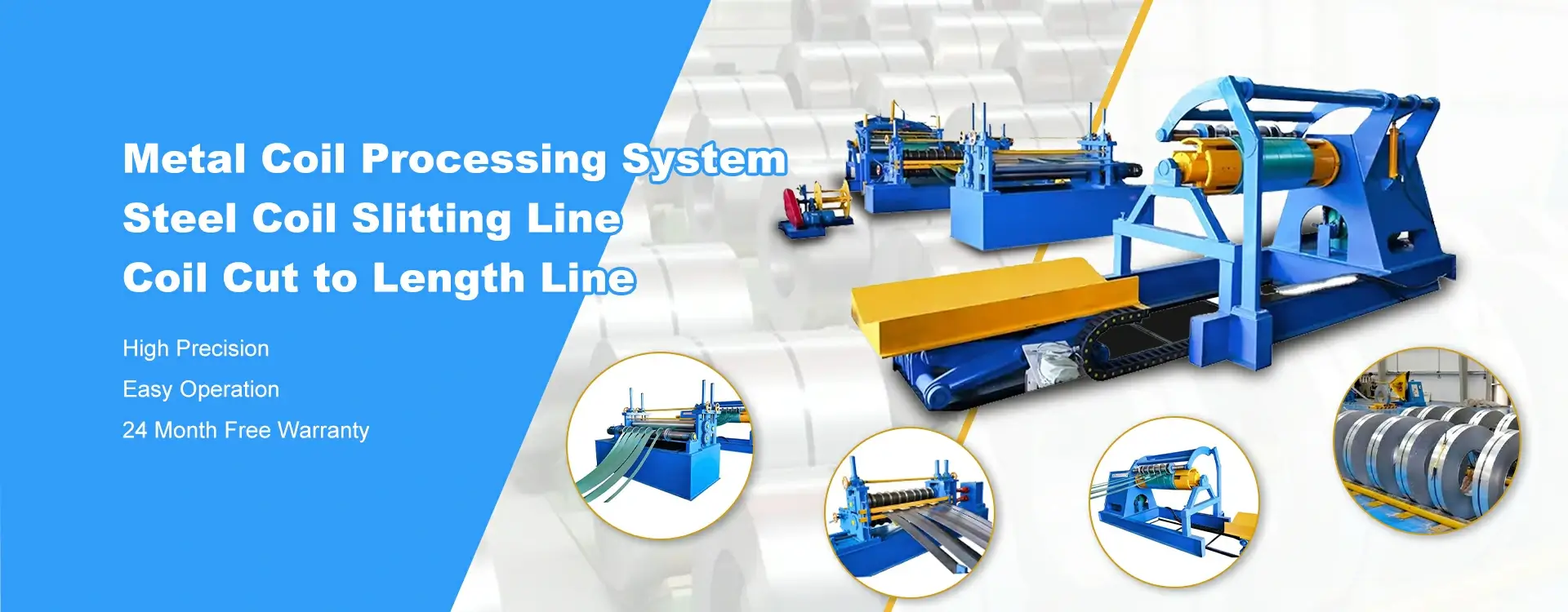

In the realm of metal processing, the slitting line plays a pivotal role, particularly in the production of narrow steel strips from wider coils. This sophisticated machinery is essential for industries that require precise dimensions and high-quality finish for their metal products. As various sectors—such as automotive, construction, and appliance manufacturing—demand specific widths of steel, the slitting line stands out as a crucial process in the supply chain.

The slitting line operates by taking a large coil of material, typically steel, and cutting it into several narrower strips according to predefined widths. The entire process starts with the uncoiling of the master coil. This requires a robust and efficient uncoiler that supports the weight and ensures a smooth unwinding of the coil. As the coil unwinds, the material passes through a series of rollers that guide it securely to the slitting section.

Once the material reaches the slitting section, a series of rotary blades are strategically positioned to slice the metal into the desired widths. The precision of the blades is critical, as any slight variance can lead to defects in the final product. Following the slitting, the newly formed strips are then carefully guided to the recoiling section. Here, each strip is wound into smaller coils or bundles, making them easier to handle and transport for further processing or delivery to customers.

slitting line

One of the significant advantages of using a slitting line is its efficiency. The process is rapid, allowing manufacturers to produce large quantities of narrow strips with minimal downtime. Furthermore, modern slitting lines are often equipped with advanced control systems that monitor various parameters—such as tension, speed, and blade sharpness—to ensure consistent quality and reduce waste.

Another important aspect is the versatility the slitting line brings to metal fabrication. Depending on the requirements, it can handle a variety of materials including stainless steel, aluminum, and even non-ferrous metals. This flexibility enables manufacturers to adapt to changing market demands and diverse customer specifications.

Quality control is also integral to the slitting line operation. Regular maintenance of the equipment, along with consistent inspection of the output strips, ensures that the final products meet industry standards. Many companies employ stringent testing procedures, such as dimensional checks and surface quality assessments, to maintain their reputation for excellence.

In conclusion, the slitting line is an essential component in the metal processing industry, delivering efficiency, precision, and versatility. As industries continue to evolve, the role of slitting lines will undoubtedly expand, driving innovation in production methodologies and meeting the ever-growing demand for specialized metal products.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025