siding panel roll forming equipment for efficient production and design customization

The Role of Siding Panel Roll Forming Machines in Modern Construction

In the ever-evolving landscape of construction and manufacturing, efficiency and reliability play crucial roles. One of the standout innovations that have significantly transformed the production of siding materials is the siding panel roll forming machine. This advanced machinery offers a multitude of benefits, making it indispensable for manufacturers and builders alike.

Understanding Siding Panel Roll Forming Machines

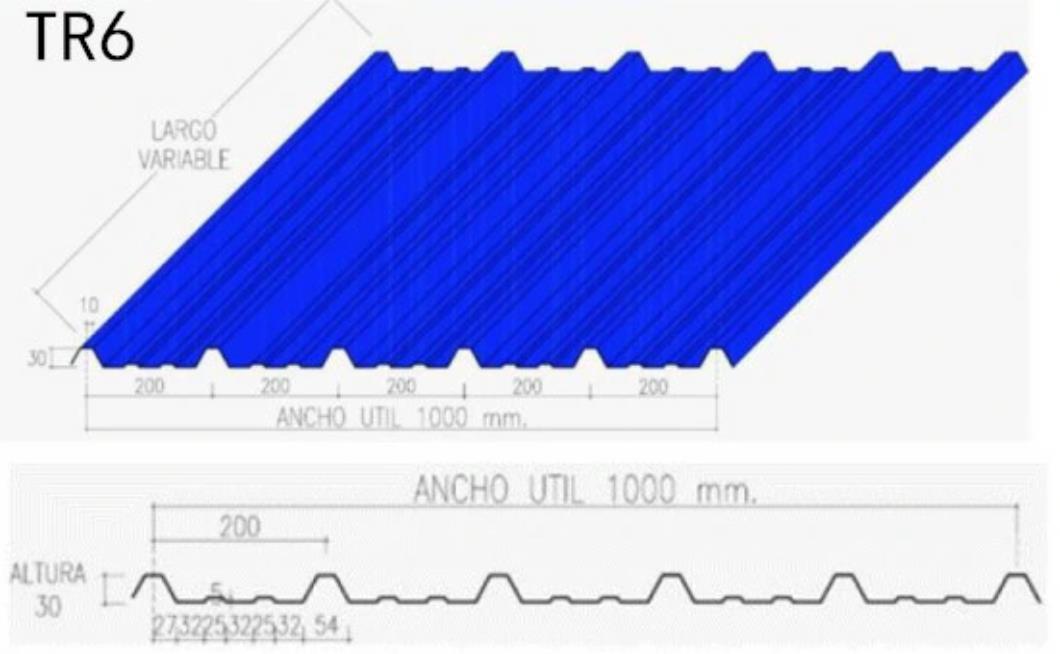

Siding panel roll forming machines are specialized equipment designed to create metal siding panels from metal coils. The process involves transforming flat metal sheets into specific profiles through a series of shaped rollers in a continuous process. This manufacturing technique allows for high-speed production while maintaining precision and uniformity in the final product.

The machines typically feature a robust construction, incorporating high-quality steel and advanced technology to ensure durability and efficiency. They can be customized to produce different profiles and sizes of siding panels, catering to the specific needs of builders and architects. As a result, these machines can accommodate a variety of materials, including steel, aluminum, and even other metals, making them versatile tools in modern construction.

Advantages of Using Siding Panel Roll Forming Machines

1. Cost Efficiency One of the primary advantages of utilizing siding panel roll forming machines is the significant reduction in labor and production costs. The automated nature of the machines means less manual intervention is needed, which helps to minimize labor costs and human errors. Additionally, producing siding panels in bulk can lead to decreased material costs over time, allowing manufacturers to maximize profitability.

siding panel roll forming machine

2. Speed and Productivity In the construction industry, time is a critical factor. Siding panel roll forming machines can produce panels at a rapid pace, dramatically increasing output compared to traditional methods. The ability to process continuous metal coils allows for the seamless production of siding materials without interruptions, facilitating quicker project timelines.

3. Customization With the capability to produce various profiles and design options, siding panel roll forming machines offer unmatched flexibility. Manufacturers can easily adjust the machine settings to create custom designs tailored to specific architectural requirements. This adaptability not only caters to the needs of individual clients but also enhances the aesthetic appeal of buildings.

4. Durability and Quality The materials used in siding panels (especially metal) are known for their longevity and resistance to environmental elements. The roll forming process ensures high-quality panels with consistent thickness and strength, which translates to enhanced durability. This longevity reduces maintenance needs and improves the overall lifecycle of the building.

5. Eco-Friendly Production The production of siding panels using roll forming machines aligns with sustainable practices. The process generates minimal waste compared to traditional cutting methods. Moreover, many metal siding materials are recyclable, further emphasizing the environmental benefits of using siding panel roll forming machines.

Conclusion

As the demand for efficient construction methods continues to rise, siding panel roll forming machines emerge as a vital asset in the industry. Their ability to produce high-quality siding panels rapidly and cost-effectively is a game changer for manufacturers and builders alike. With benefits such as customization, durability, and eco-friendliness, it is evident that siding panel roll forming machines will play a significant role in shaping the future of modern construction.

In a world where time and resources are precious, investing in advanced machinery like siding panel roll forming machines can lead to enhanced productivity and satisfaction in construction projects. Embracing this technology not only streamlines manufacturing processes but also aligns with the increasing demand for sustainable practices in the building industry. As we look ahead, the growth of siding panel roll forming technology will likely continue to influence how we approach and execute construction projects, paving the way for a more efficient and dynamic future in the field.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025