shutter strip making machine company

The Evolution of Shutter Strip Making Machines A Technological Perspective

In today's fast-paced manufacturing environment, the demand for efficient and precise production methods has never been higher. Among the key players in this transformation are shutter strip making machines, essential tools in the production of high-quality shutter strips used in various industries, including construction, automotive, and home security. This article delves into the technology behind these machines, their significance in modern production, and the future of shutter strip manufacturing.

Understanding Shutter Strip Making Machines

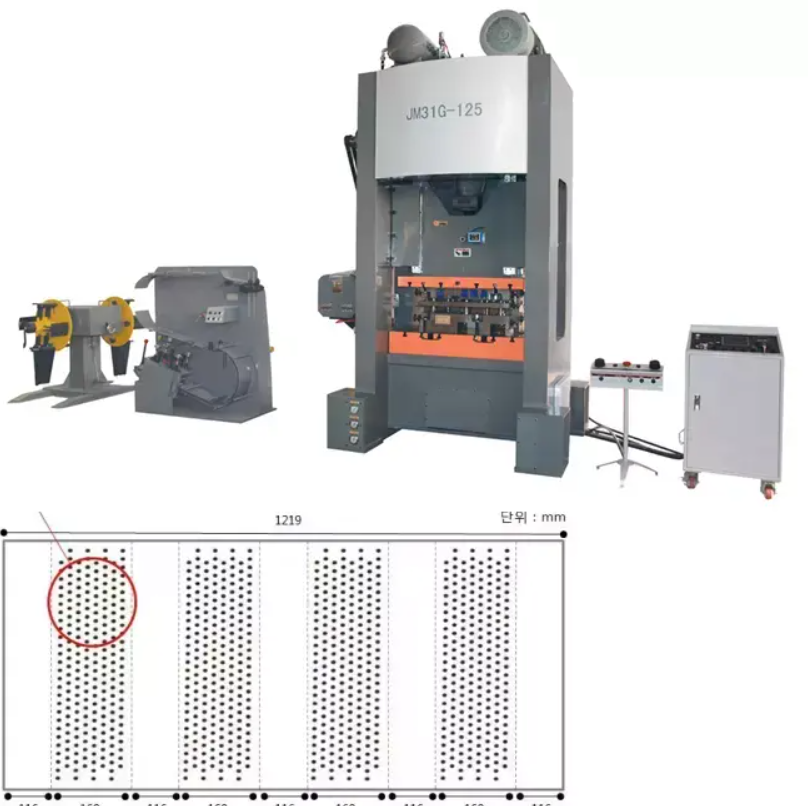

Shutter strip making machines are specialized equipment designed for the automated production of shutter strips. These strips are typically made from materials like aluminum, PVC, or composite materials, serving as integral components in roller shutters, security doors, and retractable screens. The manufacturing process generally involves cutting, shaping, and finishing the strips to ensure they meet specific quality and durability standards.

The machines themselves are marvels of engineering, incorporating advanced technology such as computer numerical control (CNC), automation, and even robotics. These innovations enhance precision, reduce waste, and improve production speed, allowing manufacturers to meet the growing demand for bespoke shutter solutions efficiently.

Key Features of Modern Machines

1. CNC Technology One of the most notable features of contemporary shutter strip making machines is their integration with CNC technology. This allows for high precision in cutting and shaping the strips according to exact specifications. The ability to program complex designs reduces human error and leads to improved product consistency.

2. Automation Automation plays a crucial role in increasing efficiency in production lines. Automated machines can operate continuously with minimal human intervention, drastically reducing labor costs and increasing output. Features such as automatic feeding and stacking systems further streamline the workflow.

3. Material Versatility Modern machines can handle different materials, allowing manufacturers to diversify their product offerings. Whether working with lightweight PVC for indoor applications or robust aluminum for outdoor use, these machines are adaptable to various needs.

shutter strip making machine company

4. Energy Efficiency With growing awareness of environmental issues, many manufacturers are focusing on energy-efficient machines. These models consume less power while maintaining high performance levels, helping companies reduce their carbon footprint and operating costs.

Significance in the Industry

The importance of shutter strip making machines extends beyond mere functionality. They are vital for ensuring that products meet strict safety and quality standards while offering customization options to clients. In the construction sector, for instance, the ability to create tailored shutter solutions for various architectural styles has become a selling point for many businesses.

Additionally, these machines contribute to the overall competitiveness of manufacturers. Companies that invest in advanced machinery can produce higher volumes at lower costs, enabling them to offer better pricing and quicker lead times to customers. This competitive edge is critical in today's global marketplace, where consumers are increasingly demanding and markets are becoming saturated.

Future Trends

Looking ahead, the future of shutter strip making machines appears promising, driven by advancements in technology and changing market demands. The integration of smart technologies such as the Internet of Things (IoT) and artificial intelligence (AI) could revolutionize the industry. IoT-equipped machines will enable real-time monitoring and predictive maintenance, reducing downtime and enhancing efficiency.

Furthermore, as sustainability becomes a priority for businesses worldwide, manufacturers of shutter strip making machines are expected to innovate toward greener solutions. This could include developing machines that utilize eco-friendly materials or implementing processes that produce less waste.

Conclusion

The evolution of shutter strip making machines reflects broader trends in manufacturing and technology. As these machines become more advanced and efficient, they will continue to play a vital role in meeting the demands of various industries. Companies that embrace these innovations will not only enhance their production capabilities but also set themselves up for success in an ever-evolving market. The future of shutter strip manufacturing looks bright, and it is a journey that is just beginning.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025