shutter roll forming machine

The Shutter Roll Forming Machine Revolutionizing the Manufacturing of Rolling Shutters

In recent years, the demand for security solutions in residential, commercial, and industrial applications has skyrocketed. One such solution that has gained immense popularity is the rolling shutter. Designed to provide protection against intruders and the elements, rolling shutters have become a staple in modern architecture. Behind the efficient production of these shutters lies an innovative machine known as the shutter roll forming machine.

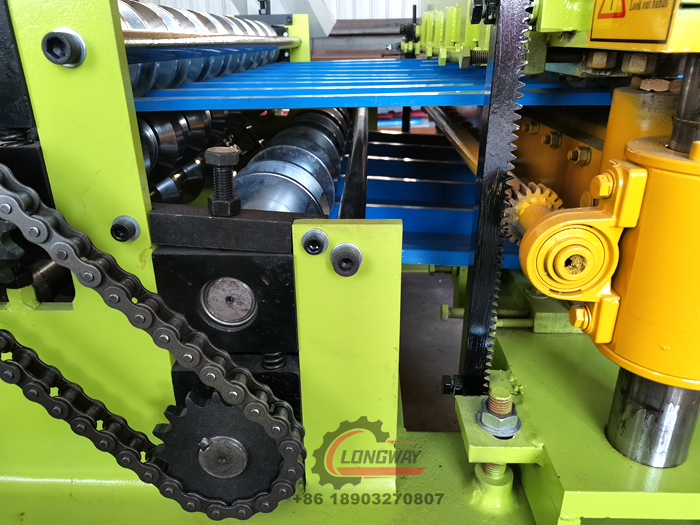

A shutter roll forming machine is specifically designed to manufacture rolling shutter profiles from metal strips, commonly made of galvanized steel, aluminum, or stainless steel. The machine operates through a continuous forming process, where flat metal sheets are fed into the machine and progressively shaped into the desired profile through a series of rollers. This method not only enhances production speed but also ensures uniformity and precision in the finished product.

Key Features and Functionalities

One of the key features of shutter roll forming machines is their robust construction and reliability. Typically made from high-quality materials, these machines are designed to withstand the rigors of continuous operation, ensuring longevity and minimal maintenance. Equipped with advanced technologies, modern machines come with CNC (Computer Numerical Control) systems that automate the forming process, allowing for increased accuracy and reduced labor costs.

Another significant advantage is the versatility of these machines. Shutter roll forming machines can produce a wide range of rolling shutter profiles, accommodating various thicknesses and sizes based on the needs of the customer. This flexibility has made them highly sought after in the market, allowing manufacturers to cater to different customer requirements without the need for extensive reconfiguration or downtime.

The Manufacturing Process

shutter roll forming machine

The production process begins with the selection of raw material sheets. Once the material is fed into the machine, it undergoes several stages of forming. Initially, the metal sheets are passed through a series of rollers that gradually bend and shape the material into the desired profile. Sensors and control systems monitor the entire process, ensuring precise dimensions are maintained.

After the shaping process, the metal profiles are cut to length based on specifications. Many shutter roll forming machines are equipped with automatic cutting systems that enhance efficiency and ensure smooth operation. The finished profiles are then stacked and prepared for dispatch to manufacturers who will assemble the rolling shutters.

Energy Efficiency and Sustainability

In today’s manufacturing landscape, energy efficiency and sustainability are crucial. Modern shutter roll forming machines are designed to minimize energy consumption while maximizing output. Innovations such as servo motor technology and regenerative braking systems have made it possible for manufacturers to reduce their carbon footprint while producing high-quality products.

Additionally, the use of recyclable materials in the production process further enhances sustainability. Manufacturers are increasingly choosing materials that can be reused or recycled at the end of their lifecycle, thus contributing to a more sustainable manufacturing model.

Conclusion

The shutter roll forming machine has revolutionized the production of rolling shutters, providing manufacturers with a reliable and efficient way to meet the growing demand for security products. With advancements in technology, these machines offer precision, versatility, and sustainability, making them an essential component in the modern manufacturing landscape. As the trend towards enhanced security and energy-efficient solutions continues to grow, the importance of shutter roll forming machines will only increase, ensuring they remain a pivotal part of the industry for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025