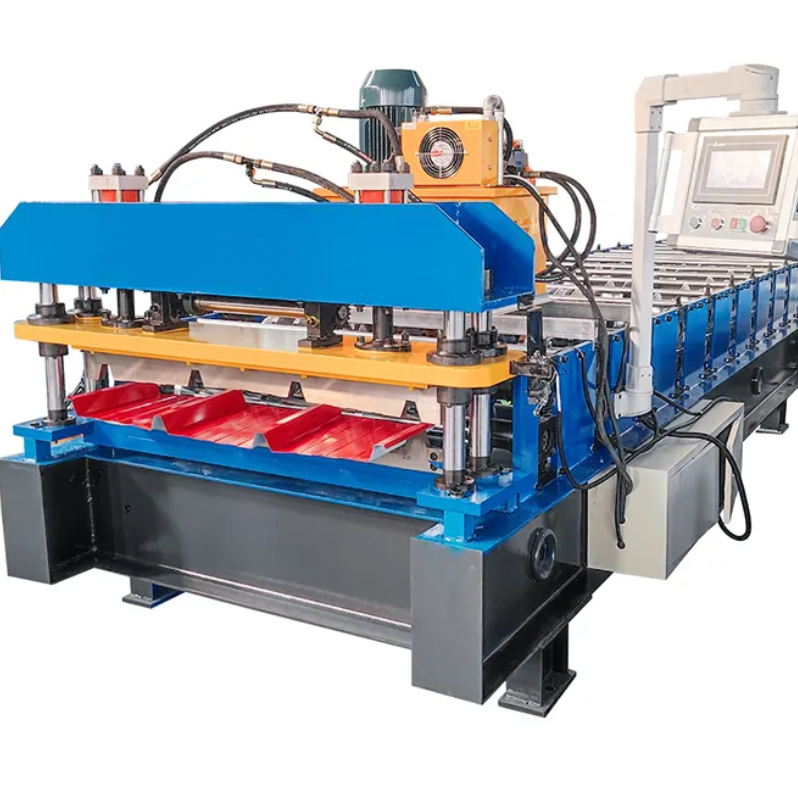

shutter roll forming machine

Understanding Shutter Roll Forming Machines Revolutionizing Industrial Production

In modern manufacturing, efficiency, precision, and versatility are paramount. One of the most significant innovations in this realm is the shutter roll forming machine. This specialized piece of equipment is designed to fabricate high-quality roller shutters and other similar products, making it a vital tool for industries that require durable and secure closures.

What is a Shutter Roll Forming Machine?

A shutter roll forming machine is a production system that transforms metal strips into roller shutter profiles through a series of sequential operations. The process involves feeding metal coils into the machine, where they are gradually shaped into the desired profile using a series of roller dies. This method not only ensures uniformity in the finished product but also allows for high-speed production, significantly reducing manufacturing time.

Key Components of the Machine

1. Uncoiler This component unwinds the metal coil and feeds it into the machine. It is crucial for maintaining an uninterrupted flow of material, which is essential for continuous production.

2. Roll Forming Station The heart of the machine, this station consists of a series of rollers that shape the metal into the desired profile. Each roller is meticulously designed to perform a specific part of the shaping process, ensuring precision and consistency.

3. Cutting Mechanism Once the metal has been formed into the required profile, it needs to be cut to the desired length. The cutting mechanism can be either a fly saw cut-off or a hydraulic cutter, depending on the machine’s specifications.

4. Control System Modern shutter roll forming machines are equipped with advanced control systems that enable operators to set parameters such as speed, temperature, and cutting length. These controls often come with digital displays and programmable functions, enhancing user-friendliness.

5. Stacker After cutting, the finished products are stacked for easy handling and storage. A well-designed stacker reduces the risk of damage and improves workflow efficiency.

Advantages of Using a Shutter Roll Forming Machine

shutter roll forming machine

1. Efficiency One of the primary advantages of using a shutter roll forming machine is its speed. These machines can produce large quantities of roller shutters in a fraction of the time it would take to manufacture them through traditional methods.

2. Cost-Effectiveness The automation and speed of the roll forming process significantly lower labor costs and reduce material waste. Companies can achieve economies of scale, enhancing profitability.

3. Customization With the flexibility to change the roller design, manufacturers can easily adapt to market demands by producing various sizes and shapes of shutters without necessitating drastic changes to the machine.

4. Durability of Products Products created with a shutter roll forming machine are known for their strength and resilience. The continuous profile design offers superior structural integrity compared to other manufacturing techniques.

5. Less Waste Generation The precision of the roll forming process means less material waste. Advanced control systems also help in optimizing material usage, further enhancing sustainability.

Applications of Shutter Roll Forming Machines

Shutter roll forming machines are widely used in several industries, including

- Construction For producing durable shutters for buildings and warehouses. - Automotive In manufacturing security shutters for vehicle storage. - Retail For fabricating storefront security closures that enhance both safety and aesthetics. - Industrial Sites Used for creating heavy-duty shutters that protect equipment and materials.

Conclusion

The shutter roll forming machine is a game-changer in the world of industrial manufacturing. With its ability to produce high-quality, durable products efficiently and cost-effectively, it meets the growing demands of various industries. As technology continues to evolve, these machines will undoubtedly become even more advanced, opening new possibilities for manufacturers and contributing to the growth of the global economy. Embracing innovations like shutter roll forming machines is essential for companies aiming to thrive in an increasingly competitive landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025