Shutter Profile Production Equipment Manufacturer and Solutions Provider

The Evolution and Significance of Shutter Profile Making Machines

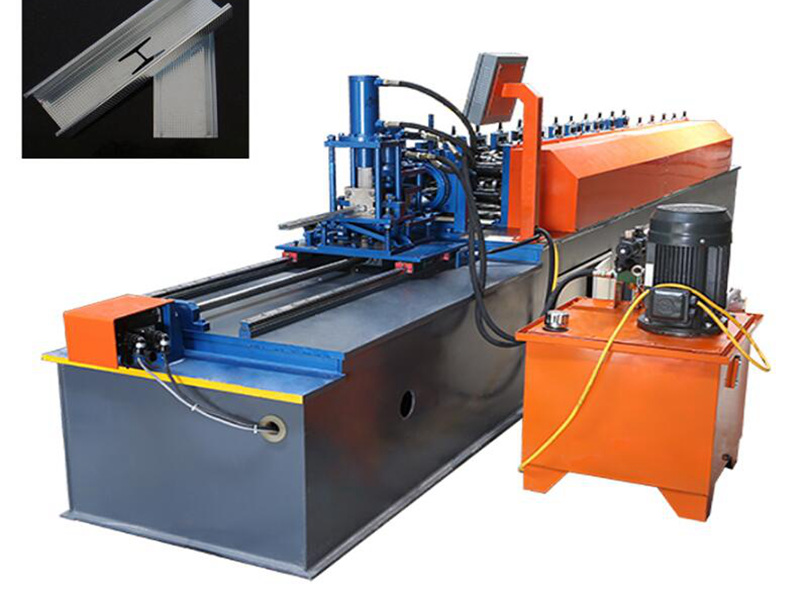

In the contemporary world of manufacturing, the production of architectural components has become increasingly sophisticated and efficient. Among the various machines that facilitate this process, shutter profile making machines play a crucial role. These machines are designed to manufacture high-quality shutter profiles that are used in various applications, such as rolling shutters for commercial and residential establishments. As urbanization continues to rise and security concerns become paramount, the demand for efficient and reliable shutter systems has surged, leading to advancements in shutter profile making technology.

The Evolution and Significance of Shutter Profile Making Machines

The importance of these machines extends beyond mere production; they significantly enhance operational efficiency. Traditionally, the manufacturing of shutter profiles involved labor-intensive methods that were not only time-consuming but also prone to errors. The automation introduced by shutter profile making machines minimizes human error, allowing companies to maintain consistent quality while increasing output rates. This automation is particularly valuable in meeting the growing demand for shutters in urban environments where safety and security are increasingly prioritized.

shutter profile making machine company

Moreover, the robustness of shutter profiles produced by these machines enhances the overall durability and lifespan of the products, further increasing their market appeal. High-quality profiles can withstand adverse weather conditions, impact, and wear over time, making them ideal for various applications, from storefronts to garages. Manufacturers are now able to offer warranties and assurances that were not feasible with traditional methods, thus enhancing customer trust and satisfaction.

In addition to their practical applications, shutter profile making machines have evolved to include environmental considerations. Many manufacturers are investing in sustainable practices by utilizing recyclable materials and implementing energy-efficient technologies in their machinery. This shift not only meets regulatory standards but also appeals to environmentally conscious consumers. As sustainability becomes a central theme in manufacturing, the integration of eco-friendly practices in shutter profile production is paving the way for a greener future in the construction industry.

The global market for shutter profile making machines is also on the rise, driven by infrastructure development and a booming construction sector. As cities expand, the demand for enhanced security solutions has never been greater. This trend offers various opportunities for manufacturers and suppliers alike, fostering innovation and competition in the industry.

In conclusion, the shutter profile making machine industry is a vital component of modern manufacturing with significant implications for construction and security. Its evolution reflects advancements in technology, efficiency, and sustainability, addressing the changing needs of consumers and the environment. As urban areas continue to grow and the importance of safety becomes ever more pronounced, the role of shutter profile making machines will undoubtedly expand, reinforcing their importance in both commercial and residential applications. These machines are not just tools for production; they represent the intersection of innovation and practicality in a rapidly evolving market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025