shutter profile machine factories

Shutter Profile Machine Factories An Overview

In the dynamic world of manufacturing, the production of shutters has evolved significantly, aided by technological advancements and the increasing demand for customizable building solutions. Shutter profile machine factories play a pivotal role in this industry, providing the equipment necessary to create different types of shutters used in residential, commercial, and industrial settings. This article explores the functions, importance, and future trends related to shutter profile machine factories.

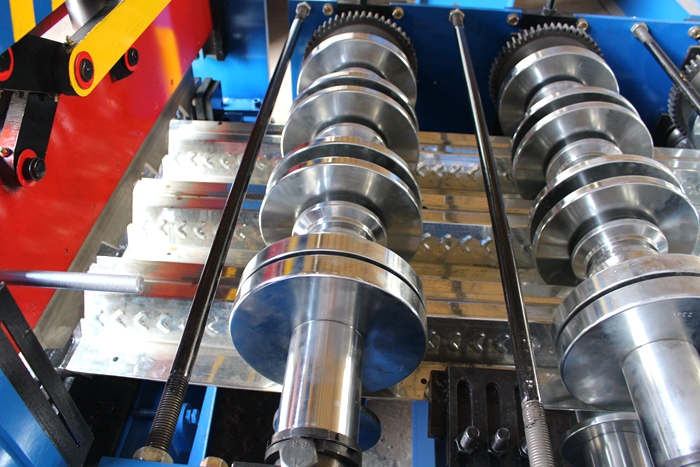

Shutters come in various forms, including roller shutters, security shutters, and decorative shutters. Each type requires specific manufacturing processes, which are primarily executed through specialized shutter profile machines. These machines are designed to cut, bend, and shape raw materials like aluminum or stainless steel into profiles that can be assembled into finished products. The primary advantage of using such machines is the level of precision and efficiency they bring to the production process.

Shutter profile machine factories are equipped with advanced technology, enabling them to produce high-quality components while minimizing waste. The incorporation of computer numerical control (CNC) technology has transformed the manufacturing landscape, allowing for greater automation and consistency. This transition from manual operations to automated processes not only speeds up production rates but also significantly reduces the risk of human error. As a result, manufacturers can fulfill large orders with a high degree of reliability and accuracy.

Sustainability has become a cornerstone of modern manufacturing, and shutter profile machine factories are no exception. Many factories integrate eco-friendly practices into their production processes. This includes using recyclable materials, energy-efficient machines, and waste reduction techniques. As customers become more environmentally conscious, factories that prioritize sustainability may have a competitive edge. Furthermore, local sourcing of materials can reduce the carbon footprint associated with transportation, making the production process even more sustainable.

shutter profile machine factories

The global market for shutters is on the rise, driven by urbanization and the need for security solutions. As more people move to urban areas, the demand for residential and commercial properties increases, leading to a greater need for effective window and door security. Shutter profile machine factories are crucial in meeting these demands, as they are capable of producing customizable shutters tailored to specific architectural styles and customer requirements. This adaptability is key for businesses that want to stay relevant and competitive in a crowded marketplace.

Looking ahead, the future of shutter profile machine factories is promising, buoyed by ongoing advancements in technology. The introduction of Industry 4.0 concepts—including the Internet of Things (IoT), artificial intelligence, and big data—enables factories to optimize their operations. For instance, IoT sensors can monitor machine performance in real time, helping to predict potential failures and reduce downtime. Additionally, data analytics can provide insights into production efficiency, enabling factories to refine their processes continuously.

Moreover, the integration of artificial intelligence can enhance the customization process. AI-driven design tools allow manufacturers to create complex shutter patterns that cater to individual customer preferences. This level of customization can lead to greater customer satisfaction and loyalty, as clients receive products that meet their specific needs.

In conclusion, shutter profile machine factories are essential players in the manufacturing industry, driving innovation and providing high-quality products to meet the growing demand for shutters. By embracing technological advancements and sustainable practices, these factories can enhance their production capabilities and remain competitive in a changing marketplace. As we move into the future, it is clear that the role of technology in optimizing manufacturing processes will continue to expand, presenting new opportunities for growth and efficiency in the shutter production industry. The evolution of shutter profile machine factories signals not just progress in manufacturing, but also a commitment to sustainability and customization, aligning with contemporary consumer expectations.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025