Shutter Patti Production Machine Manufacturing Facility Overview and Insights

The Shutter Patti Making Machine Factory Revolutionizing the Manufacturing Process

In today's fast-paced world, the demand for innovative machinery stands at an all-time high, particularly in industries such as construction, interior design, and manufacturing. Among the many machines that have emerged in this sector is the shutter patti making machine, a revolutionary piece of equipment that has significantly changed how shutter patties are produced. This article delves into the intricacies of shutter patti making machine factories, their significance, and what to expect from the future developments in this field.

Understanding Shutter Patties

Before diving into the machinery, it is essential to understand what shutter patties are. Shutter patties are essential components used primarily in the construction of roller shutters, garage doors, and various types of fencing and barriers. These components are crucial for both security and aesthetics, providing durability and strength while also enhancing the visual appeal of buildings and establishments. The quality of shutter patties directly affects the overall efficacy and longevity of the roller shutter systems.

The Need for Automation

Traditionally, the production of shutter patties was a labor-intensive process that involved a lot of manual work. This not only increased production time but also opened the door to human error, ultimately affecting the quality of the final product. With advancements in technology, the introduction of shutter patti making machines has streamlined this process. A shutter patti making machine can efficiently automate the production line, ensuring consistent quality and significantly reducing the time taken to manufacture these essential components.

The Machinery Behind Production

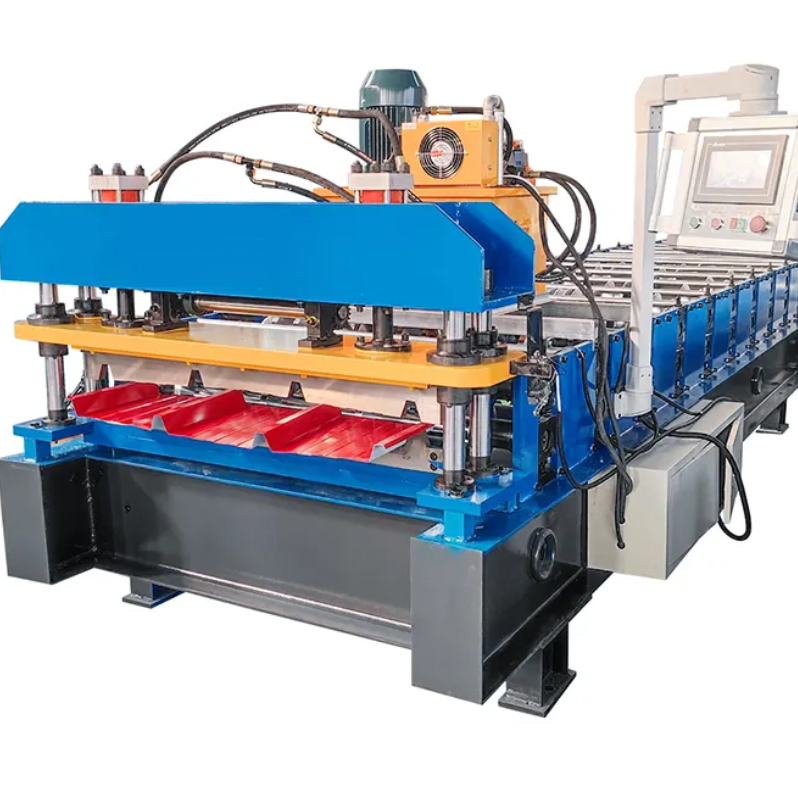

Shutter patti making machines operate on a variety of principles, primarily focusing on the processes of cutting, rolling, and assembling metals or composite materials. These machines are equipped with heavy-duty rollers and automated cutting tools that can adapt to the specific dimensions of the patties needed. For factories, this means they can produce patties in various sizes and designs with high precision and minimal waste.

The application of computerized controls in modern machines allows for easy customization. Operators can input specific requirements, and the machine adjusts to produce the desired output without the need for extensive manual intervention. This automation not only enhances productivity but also improves worker safety by minimizing exposure to potentially hazardous manual operations.

shutter patti making machine factory

Quality Control and Efficiency

Quality control remains a pivotal aspect of the manufacturing process. Established shutter patti making machine factories incorporate stringent quality assurance protocols. This may involve real-time monitoring systems that can spot defects during production, ensuring that only the highest quality patties are delivered. Efficient quality control translates to fewer returns, reduced costs, and enhanced customer satisfaction, making factories more competitive in a crowded market.

Sustainability in Manufacturing

As the world moves towards more sustainable manufacturing practices, shutter patti making machine factories are also embracing eco-friendly methods. Manufacturers are focusing on using recyclable materials and implementing energy-efficient processes to minimize their environmental footprint. Innovations in technology have led to the development of machines that utilize less energy while maintaining high productivity levels, merging efficiency with sustainability seamlessly.

The Future of Shutter Patti Manufacturing

Looking ahead, the future of shutter patti making machine factories appears promising. The industry is gradually integrating advanced technologies such as artificial intelligence and machine learning, which can further improve efficiency and reduce production costs. These technologies enable predictive maintenance of machines, ensuring they operate at optimal levels and reducing downtime.

Moreover, the increasing global emphasis on security and safety is expected to drive demand for roller shutters and high-quality shutter patties. As urbanization continues to expand, so too does the necessity for robust security solutions, placing shutter patti making machine factories in a pivotal position in the manufacturing landscape.

Conclusion

The shutter patti making machine factory stands as a testament to the advancements in manufacturing technology. By embracing automation, maintaining strict quality control, and focusing on sustainability, these factories are not only meeting the current demands of the market but are also laying the groundwork for future innovations. As technology continues to evolve, one can only anticipate further enhancements in the efficiency and quality of shutter patti production, benefitting industries and consumers alike.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025