shutter door strip roll forming machine

The Advancements and Importance of Shutter Door Strip Roll Forming Machines

In the ever-evolving landscape of manufacturing technology, the roll forming technique stands out for its efficiency and precision, particularly in the production of shutter door strips. Shutter door strip roll forming machines play a critical role in producing the essential components that comprise modern security systems for commercial and industrial buildings, as well as residential properties. This article delves into the significance, operation, and advancements of these machines in the manufacturing world.

Understanding Roll Forming Technology

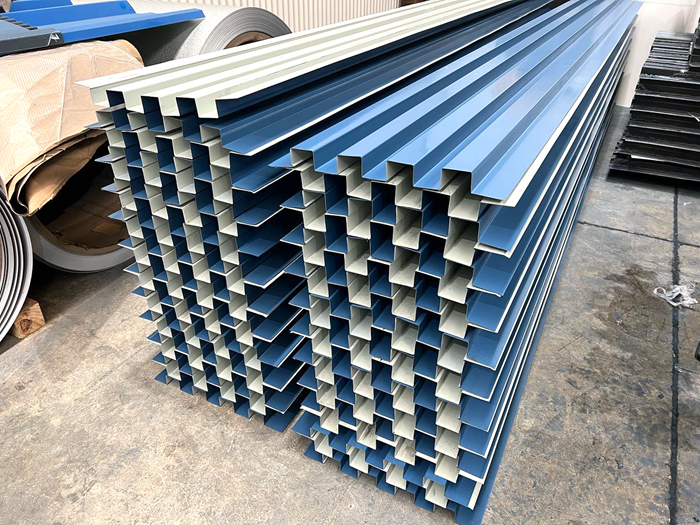

Roll forming is a continuous bending operation in which a long strip of metal, typically coiled steel or aluminum, is fed through a series of rollers. As the strip passes through, it is progressively shaped into a desired cross-section. This process allows for the mass production of uniform and high-quality components, which are essential in constructing sturdy and durable shutter doors.

Shutter doors, often used in warehouses, storefronts, and garages, require robust materials to withstand heavy use and potential break-ins. Therefore, the design and manufacturing process of the shutter door strips must prioritize strength without compromising aesthetics or functionality.

The Role of Shutter Door Strip Roll Forming Machines

Shutter door strip roll forming machines are specifically designed to produce the strips that form the slats of roller shutters. These machines consist of several crucial components decoilers, roll forming stations, cutting stations, and computerized control systems. The automation involved significantly enhances the speed and accuracy of the production process, allowing manufacturers to produce large quantities of shutter strips in a fraction of the time it would take using traditional methods.

One of the most significant advantages of these machines is their ability to create customized profiles. Manufacturers can adjust the roll forming setup to produce a wide variety of strip shapes and sizes, catering to different market needs. This versatility allows for the production of unique designs that can match client specifications, ensuring that window and door shutters not only provide security but also complement the building's aesthetic.

shutter door strip roll forming machine

Energy Efficiency and Sustainability

Modern shutter door strip roll forming machines are increasingly designed with energy efficiency in mind

. With a growing global emphasis on sustainability and reducing carbon footprints, manufacturers are looking for ways to minimize energy consumption during the production process. Advanced machines often include features such as energy-efficient motors and reduced material waste, which contribute to both cost savings and environmental benefits.Additionally, the materials used in the manufacturing of shutter door strips are becoming more eco-friendly, with many manufacturers shifting towards recycled metals. This trend not only supports sustainability but also aligns with consumer preferences, as more customers prioritize eco-conscious products.

The Future of Shutter Door Strip Roll Forming Machines

The future of shutter door strip roll forming machines looks promising, with ongoing advancements in technology such as Industry 4.0 and artificial intelligence. Integrating smart technology into these machines allows for real-time monitoring and predictive maintenance, ensuring maximum operational efficiency. Manufacturers will benefit from reduced downtime and improved production quality, leading to higher customer satisfaction.

Moreover, as urban development continues to surge, the demand for versatile and high-quality shutter door systems is expected to rise. This will place greater emphasis on the importance of efficient machinery capable of meeting large-scale production needs while offering customization options.

Conclusion

In conclusion, shutter door strip roll forming machines are vital components of the manufacturing landscape, particularly in the context of security solutions. Their ability to produce high-quality, customized strips efficiently underscores their significance in the production of roller shutters. With advancements in technology, energy efficiency, and environmental sustainability, these machines are not only keeping pace with modern manufacturing demands but are also paving the way for a more innovative and responsible future in the industry. As businesses continue to adapt to consumer needs and market trends, the role of roll forming in producing shutter door strips will only expand, promoting growth and offering enhanced security solutions for all types of buildings.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025