Shutter Door Roll Forming Machine Manufacturer for Durable and Efficient Solutions

The Rise of Shutter Door Roll Forming Machine Factories

In recent years, the demand for effective and efficient shutter door solutions has surged, leading to a significant rise in the establishment of shutter door roll forming machine factories

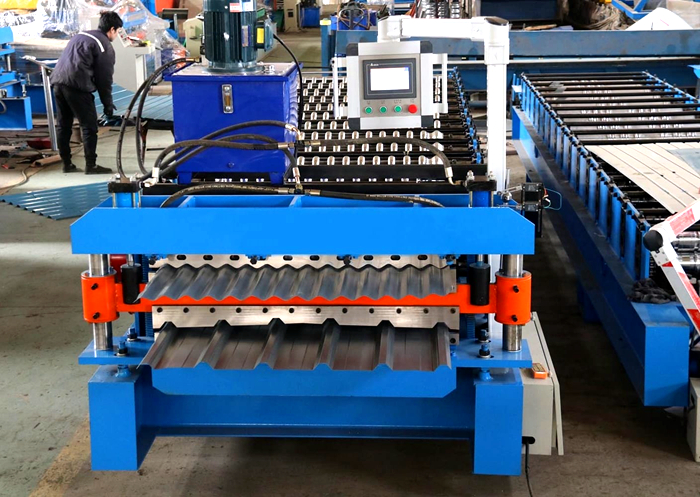

. These factories are pivotal in the manufacturing of high-quality roller shutters that cater to various sectors including residential, commercial, and industrial applications.Shutter door roll forming machines are designed to produce roller shutter doors that are not only functional but also aesthetically pleasing. They operate by rolling metal strips, typically galvanized steel or aluminum, into various profiles that form the slats of the shutter. This process involves several steps, including decoiling, feeding, rolling, and finally cutting the formed slats to the desired length. The automation involved in these machines ensures precision and consistency, which is crucial for meeting market standards and customer requirements.

One of the primary advantages of shutter door roll forming machine factories is their ability to produce customized solutions. Each client may have specific needs based on the intended use of the shutter door. Factories can easily adjust the machine settings to create different slat designs, sizes, and thicknesses. This flexibility not only enhances customer satisfaction but also allows manufacturers to tap into niche markets.

shutter door roll forming machine factory

Moreover, advancements in technology have revolutionized the manufacturing process. Modern machines are equipped with computer numerical control (CNC) systems that ensure high precision and reduce waste. Additionally, features such as automated cutting and stacking streamline production, leading to higher output rates and reduced labor costs. As a result, factories can meet the growing demand without compromising on quality.

Sustainability is another crucial aspect that has come to the forefront in recent years. Many shutter door roll forming machine factories are adopting eco-friendly practices by utilizing recyclable materials and minimizing waste during production. This not only appeals to environmentally conscious consumers but also aligns with global trends toward sustainability in manufacturing.

In conclusion, the emergence of shutter door roll forming machine factories is a response to the increasing demand for versatile and durable shutter solutions. With their ability to offer customized products, incorporate advanced technologies, and focus on sustainability, these factories are well-positioned to thrive in a competitive market. As the need for effective security and aesthetic solutions grows, the role of these factories will only become more significant, shaping the future of the shutter door industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025