Sheet Metal Roofing Roll Forming Equipment Manufacturer

The Sheet Roof Roll Forming Machine Factory Innovation in Metal Roofing Solutions

In the construction and architecture industry, the importance of quality roofing cannot be overstated. Roofing systems not only provide essential protection against the elements but also play a significant role in enhancing the aesthetic appeal of buildings. To meet the increasing demand for innovative, durable, and cost-effective roofing solutions, the sheet roof roll forming machine factory has emerged as a key player in modern manufacturing.

What is a Sheet Roof Roll Forming Machine?

A sheet roof roll forming machine is a specialized piece of equipment that converts flat sheets of metal into various roofing profiles and designs through a continuous rolling process. This machine typically consists of multiple rollers that shape the metal as it passes through, allowing for a variety of designs and thicknesses to be produced efficiently. The versatility of these machines enables manufacturers to create anything from simple corrugated sheets to more complex standing seam panels, catering to a diverse range of construction needs.

Key Features and Advantages

1. Efficiency and Speed One of the primary advantages of using roll forming technology is the speed of production. Once set up, these machines can produce large volumes of roofing materials in a fraction of the time that traditional manufacturing methods would require. This efficiency translates to lower labor costs and shorter project timelines.

2. Precision Engineering Roll forming machines are engineered for high precision. They can produce consistent, uniform products that meet strict tolerances. This is crucial in roofing applications, where even minor variations can lead to significant issues in installation and water drainage.

3. Versatility in Designs Manufacturers can customize the roll forming machines to produce specific profiles tailored to the needs of their clients. This flexibility allows them to cater to a wide range of architectural styles and requirements, ensuring that builders and architects have access to the materials they need for their projects.

4. Reduced Waste The roll forming process is highly efficient and minimizes material waste. As the flat sheets are continuously formed into desired shapes without significant cut-offs, manufacturers can maximize the use of raw materials, making the process more environmentally friendly.

5. Cost-Effective Solutions The combination of speed, efficiency, and reduced waste means that roll-formed roofing materials can be produced at lower costs compared to traditional methods. This cost-effectiveness is appealing to builders and developers who are often working within tight budget constraints.

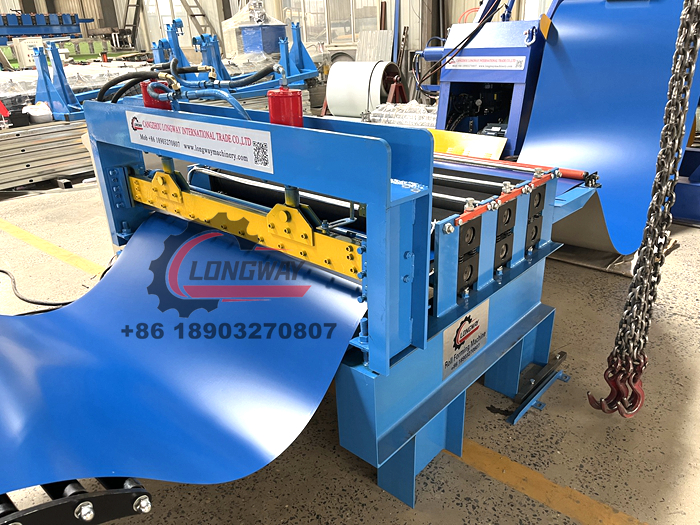

sheet roof roll forming machine factory

The Manufacturing Process

The manufacturing process at a sheet roof roll forming machine factory typically involves several key stages

1. Material Preparation High-quality metal sheets are procured, often made from steel or aluminum. These sheets may undergo a pre-treatment process to enhance their corrosion resistance and overall durability.

2. Roll Forming The metal sheets are fed into the roll forming machine, where they pass through a series of rollers that gradually shape the material into the desired profile. The machine can adjust the speed and pressure to accommodate different material thicknesses and profiles.

3. Cutting and Finishing Once the sheets have been formed, they are cut to length according to the specifications of the order. Additional finishing processes may include coating or painting to enhance aesthetics and protect against the elements.

4. Quality Control Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that the final products meet industry standards and customer expectations.

The Future of Roofing Solutions

With the ongoing advancements in technology, the sheet roof roll forming machine factory is poised for further innovation. Automation, artificial intelligence, and smart manufacturing technologies are beginning to revolutionize the industry, enhancing efficiency and precision even further. As sustainable building practices become increasingly important, the factory is also likely to focus on producing eco-friendly materials and exploring ways to reduce its carbon footprint.

In conclusion, the sheet roof roll forming machine factory represents a significant evolution in the roofing industry. By embracing modern technology and innovative manufacturing processes, these factories are not only meeting the current demand for high-quality roofing materials but also paving the way for sustainable building solutions in the future. With such advancements in place, the skyline of tomorrow will undoubtedly be crafted with precision and care.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025