sheet roll forming machine factories

The Evolution of Sheet Roll Forming Machines Transforming the Metal Fabrication Industry

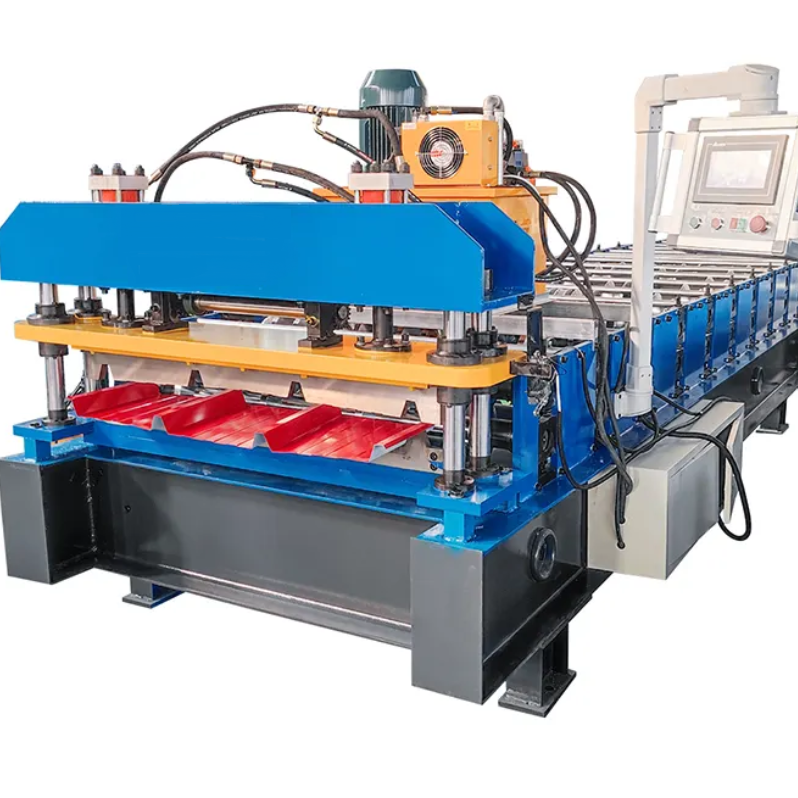

In today’s rapidly evolving manufacturing landscape, the demand for precision and efficiency has driven innovations across various sectors. Among these advancements, sheet roll forming machines have emerged as pivotal players in the metal fabrication industry. These machines are specifically designed to convert flat metal sheets into complex shapes and profiles, catering to a plethora of applications, including construction, automotive, and general manufacturing.

Understanding Sheet Roll Forming Machines

At its core, a sheet roll forming machine works by feeding a continuous strip of metal, which is progressively shaped into desired configurations through a series of rollers. This technique offers significant advantages over traditional methods, primarily due to its ability to produce high volumes of consistent products with minimal material waste. The automated nature of these machines also enhances productivity, thereby reducing labor costs and lead times in production processes.

The versatility of sheet roll forming machines is one of their most remarkable attributes. They can create a wide range of profiles such as roofing sheets, wall panels, C and Z purlins, and even specialized components for the automotive sector. Moreover, advancements in technology have allowed manufacturers to customize these machines to meet specific production needs, making them indispensable tools in modern fabrication processes.

Key Features and Innovations

Contemporary sheet roll forming machines are equipped with state-of-the-art technology that ensures precision, reliability, and efficiency. Features such as Computer Numerical Control (CNC) systems allow operators to program intricate designs with accuracy, significantly reducing the chances of error. Additionally, some machines now incorporate automatic feeding and stacking systems that streamline workflow, further enhancing productivity.

Recent innovations have also led to the development of hybrid machines capable of combining roll forming with additional processes, such as cutting and welding. This integration not only saves time but also ensures that components are engineered to the highest standards of quality. As industries continue to pursue lean manufacturing principles, the role of these versatile machines becomes increasingly critical.

The Impact on Various Industries

sheet roll forming machine factories

The influence of sheet roll forming machines transcends just manufacturing; their impact can be felt across multiple sectors. In the construction industry, for example, the capacity to produce lightweight yet robust metal components has revolutionized modern building techniques. Roofs, panels, and frames created using roll forming technology offer enhanced durability and aesthetic appeal, meeting the demands of contemporary architecture.

In the automotive sector, where lightweight materials are crucial for fuel efficiency without compromising safety, sheet roll forming machines play an integral role. By producing high-strength components that are also lightweight, manufacturers can create vehicles that abide by stringent regulatory standards while optimizing performance.

Furthermore, the ongoing trend towards sustainability in manufacturing has prompted many factories to adopt roll forming technology. By minimizing material waste and energy consumption, these machines align with eco-friendly practices, promoting a greener industry.

Challenges and Future Prospects

While the advantages of sheet roll forming machines are evident, there are challenges that manufacturers must navigate. The initial investment and maintenance costs can be significant, especially for small to medium-sized enterprises. Additionally, as technology advances, staying updated with the latest innovations can be demanding.

However, the future for sheet roll forming technology looks promising. With the integration of Industry 4.0 concepts such as IoT and AI, factories are evolving into smart manufacturing units. Predictive maintenance, enhanced monitoring systems, and data analytics will further optimize the performance and longevity of sheet roll forming machines.

Conclusion

In summary, sheet roll forming machines are at the forefront of the metal fabrication industry, driving efficiency, precision, and quality across numerous applications. As technology continues to advance, these machines will undoubtedly play a crucial role in shaping the future of manufacturing. Embracing innovation while addressing existing challenges will be essential for factories aiming to remain competitive and sustainable in an ever-changing market landscape. Whether in construction, automotive, or manufacturing, the versatility and efficiency of sheet roll forming machines will continue to transform the way we approach metal fabrication, paving the way for future innovations.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025