Sheet Metal Roll Forming Machine Manufacturers and Suppliers

The Rise of Sheet Roll Forming Machine Factories A Comprehensive Overview

In the modern manufacturing landscape, the demand for precision and efficiency has led to significant advancements in production technology. One of the standout innovations in this field is the sheet roll forming machine. These specialized machines are designed for the continuous shaping of metal sheets into various profiles, making them invaluable in numerous industries, from construction to automotive manufacturing.

Understanding Sheet Roll Forming Machines

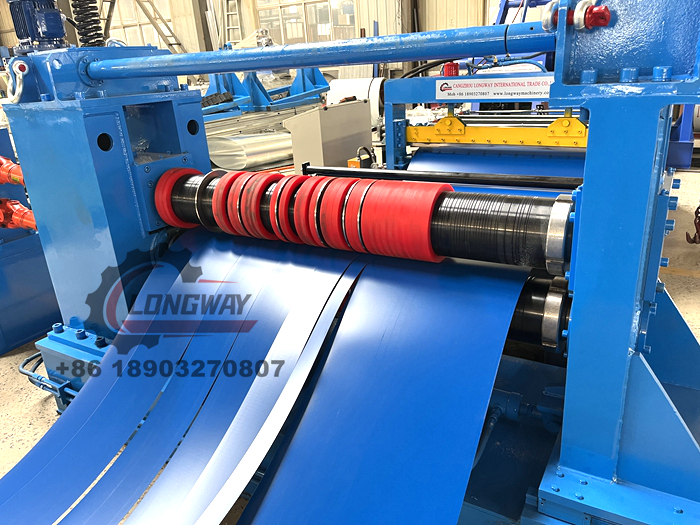

Sheet roll forming machines operate by feeding metal sheets through a series of rollers that gradually shape the material into the desired configuration. This process, often referred to as cold forming, allows manufacturers to create complex profiles with tight tolerances and high repeatability. Common applications include the production of roofing panels, purlins, gutters, and other structural components essential in construction, as well as parts for appliances and vehicles.

The versatility of roll forming technology is a key driver of its adoption. Factories can customize setups to produce specific profiles and adapt to different material types, including steel, aluminum, and even copper. This flexibility not only streamlines production but also reduces waste, as the process often requires less material than traditional methods like stamping or bending.

The Growing Demand for Factory Automation

As the global market continues to evolve, the push for factory automation is becoming increasingly prominent. Sheet roll forming machine factories are at the forefront of this trend. By implementing automated systems, manufacturers can enhance precision, reduce labor costs, and increase production speeds. Automated roll forming lines equipped with advanced robotics and computer numerical control (CNC) technologies can produce high-quality components with minimal human intervention.

Furthermore, Industry 4.0—characterized by the integration of smart technology into manufacturing—has had a profound impact on the operation of sheet roll forming machine factories. Sensors and IoT devices enable real-time monitoring of machine performance, while sophisticated software provides insights for predictive maintenance. This shift not only improves efficiency but also extends the lifespan of equipment, resulting in lower overall operational costs.

sheet roll forming machine factories

Challenges in the Sheet Roll Forming Industry

Despite the numerous advantages, sheet roll forming machine factories face several challenges. One significant issue is the need for skilled labor. While automation reduces the requirement for manual labor, skilled technicians and engineers are essential to operate and maintain complex machinery. There is a growing concern over the availability of such talent in many regions, prompting factories to invest in training and development programs.

Additionally, fluctuations in raw material prices can impact production costs. With the recent disruptions in global supply chains, manufacturers must remain agile and prepared to adapt to changes in material availability and pricing. Diversifying suppliers and maintaining inventory can mitigate some of these risks, yet it requires careful planning and management.

The Future of Sheet Roll Forming Machine Factories

Looking ahead, the future of sheet roll forming machine factories appears promising. The relentless quest for efficiency, sustainability, and innovation means that this sector will likely continue to thrive. The rise in construction and infrastructural projects globally, coupled with an increasing focus on lightweight materials, positions roll forming technology as a pivotal solution for modern manufacturing needs.

Moreover, as environmental concerns gain prominence, there is an encouraging shift toward more sustainable manufacturing practices. Factories are now exploring ways to use recycled materials and implement greener processes, reducing the overall environmental footprint of production. Innovations in machine design and energy-efficient technologies will further support this transition.

In conclusion, sheet roll forming machine factories play a crucial role in the contemporary manufacturing world. Their ability to produce high-quality components efficiently positions them as leaders in industrial production. As they navigate challenges and embrace modern technologies, these factories will remain vital to various industries, driving innovation and sustainable practices in the years to come. The continuous evolution of this sector not only addresses current market needs but also sets the stage for a resilient and adaptive manufacturing future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025