sheet roll forming machine companies

The Evolution and Importance of Sheet Roll Forming Machines

In the world of manufacturing, the demand for high-quality and precision-engineered products continues to rise. Among the technologies that are reshaping various industries, sheet roll forming machines have emerged as essential equipment in the metal fabrication process. This innovation enables the production of complex shapes and profiles from sheet metal, making it a vital component in sectors ranging from construction to automotive manufacturing.

Understanding Sheet Roll Forming

Sheet roll forming is a continuous manufacturing process that transforms flat sheets of metal into desired shapes by passing them through a series of rollers. Each pair of rollers progressively alters the metal’s shape, resulting in a wide variety of products such as roofing panels, wall systems, and structural components. The efficiency and precision of roll forming machines significantly reduce production time and material waste.

The machines are typically designed to handle various materials, including aluminum, steel, and copper. They can produce parts in different thicknesses and lengths, tailored to specific applications. The versatility of roll forming makes it invaluable in creating products that meet industry standards and customer specifications.

The Mechanism of Roll Forming Machines

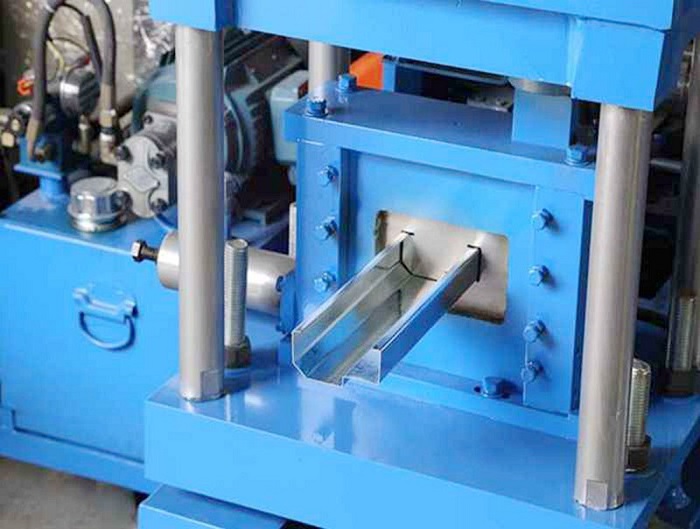

A typical sheet roll forming machine consists of several critical components, including a decoiler, feed mechanism, roll forming section, and cutoff unit. The process begins with the decoiler, which unwinds the metal sheet and feeds it into the roller system. Here, the sheet is guided through multiple rollers that reshape it as it passes through. The final stage involves a cutoff unit that slices the profiled metal into the required lengths.

Modern roll forming machines are equipped with advanced technologies, ensuring better control over the manufacturing process. Computer Numerical Control (CNC) systems allow manufacturers to fine-tune machine parameters, enhancing precision and reducing human error. Furthermore, improvements in automation and robotics have led to increased production speeds and reduced labor costs.

Benefits of Using Roll Forming Machines

sheet roll forming machine companies

The advantages of utilizing sheet roll forming machines are considerable. One of the primary benefits is the ability to produce parts with complex geometries consistently. The process facilitates high-volume production and enables manufacturers to achieve tight tolerances, which is crucial for applications where precision is paramount.

Another significant advantage is material efficiency. Roll forming produces minimal scrap metal, optimizing material usage and reducing production costs. Additionally, the strength-to-weight ratio of roll-formed products is often superior, contributing to the durability of finished goods. This characteristic is particularly beneficial in the construction and automotive industries, where structural integrity is a priority.

Major Sheet Roll Forming Machine Companies

Several companies have established themselves as leaders in the sheet roll forming machine industry. Firms such as Formtek, Grasselli, and B & B Manufacturing offer a range of solutions tailored to different manufacturing needs. These companies focus on innovation, providing advanced machinery that incorporates the latest technological advancements.

Formtek, for instance, is renowned for its customizable roll forming machines that accommodate various production requirements. Grasselli specializes in high-precision machinery designed for intricate profiles, while B & B Manufacturing focuses on providing robust solutions for heavy-duty applications.

Future Trends in Roll Forming Technology

As industries evolve, the future of sheet roll forming machines looks promising. A significant trend is the increased integration of automation and artificial intelligence, allowing for smarter manufacturing processes. This not only enhances operational efficiency but also enables predictive maintenance, reducing downtime and costs associated with repairs.

Sustainability is another trend influencing the development of roll forming machines. As manufacturers strive to reduce their environmental footprint, the focus is shifting towards equipment that minimizes energy consumption and optimizes material reuse.

In conclusion, sheet roll forming machines play a pivotal role in modern manufacturing. Their ability to produce consistent, high-quality products while optimizing material use positions them as essential tools in various industries. As technology continues to advance, the capabilities and efficiencies of these machines are likely to expand, further solidifying their importance in the manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025